Method for synthesizing CdTe semiconductor fluorescence nanocrystalline material and synthesizing system thereof

A technology of fluorescent nano and crystal materials, which is applied in the field of preparation of nano crystal materials, can solve the problems of complex synthesis process, high toxicity, and harsh conditions, and achieve the effects of low preparation cost, good fluorescent properties, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

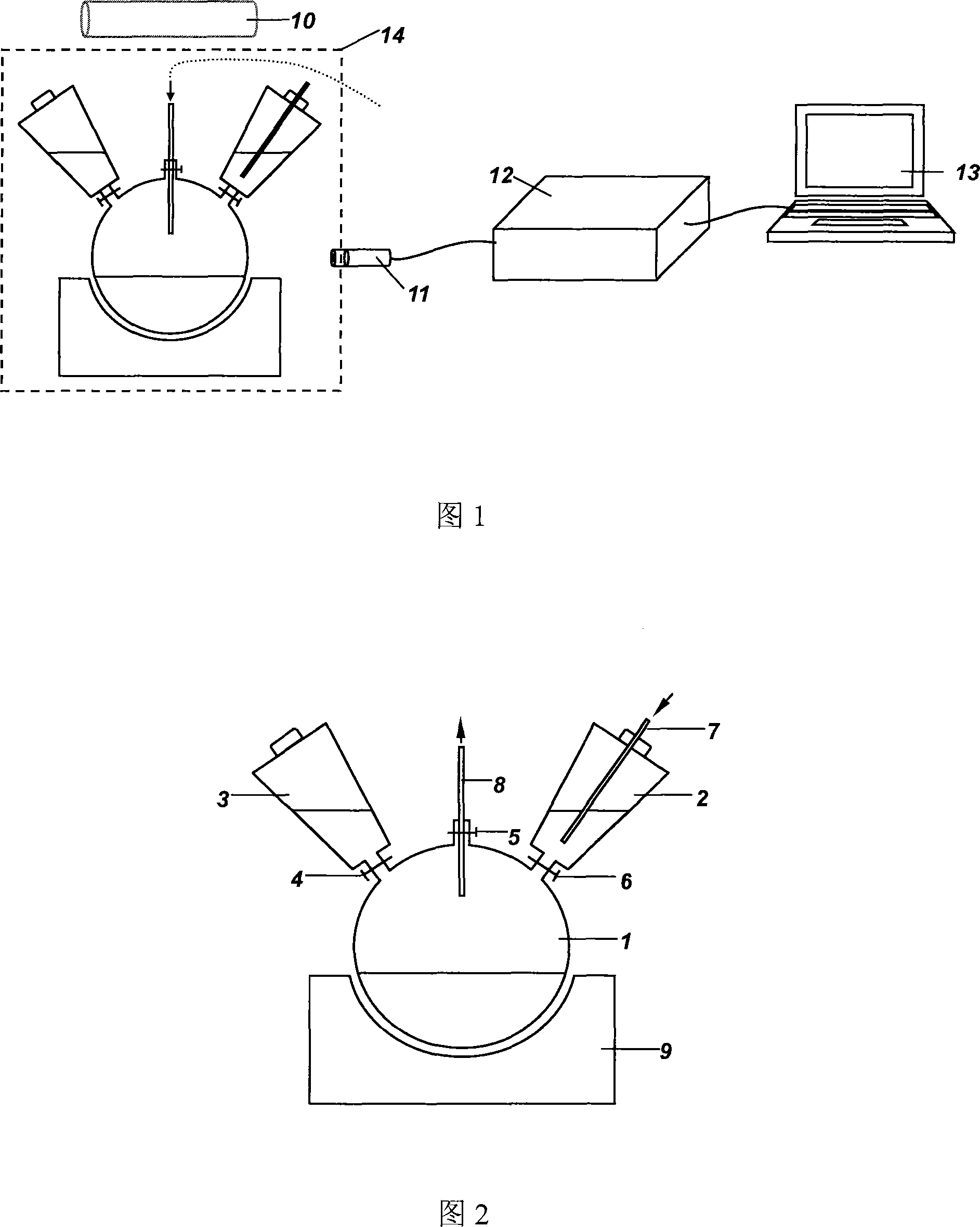

[0029] 1) Preparation of tellurium source

[0030] The process is: take 90ml of water and put it into the three-necked flask 1, then add 2.4mg of NaBH 4 and 4 mg tellurium powder, NaBH 4 The molar ratio of tellurium powder and tellurium powder is 2:1, and high-purity argon gas is introduced through the feeding pipe 8 directly above the three-necked flask 1, and the air in the three-necked flask 1 is evacuated, and the magnetic stirring device 9 is evenly stirred at room temperature, and the NaBH 4 React with tellurium powder for 60 minutes, the reaction equation is: Te+NaBH 4 +H 2 O→NaHTe+Na 2 B 4 o 7 +H 2 ↑, the products included in the solution after the reaction are NaHTe, NaHTe 2 B 4 o 7 and H 2 , the NaHTe content in the solution is 0.32mmol / l. If the hydrogen produced increases the pressure in the three-necked flask 1 and affects the addition of other substances, it can be decompressed by opening the discharge valve 5 .

[0031] 2) Preparation of cadmium sour...

Embodiment 2

[0039] 1) Preparation of tellurium source

[0040] The process is: take 90ml of water and put it into the three-neck flask 1, then add 240mgNaBH4 and 90mg tellurium powder, NaBH 4 The molar ratio of tellurium powder to tellurium powder is 9.2:1. High-purity argon gas is introduced through the feeding pipe 8 directly above the three-necked flask 1, and the air in the three-necked flask 1 is evacuated. At room temperature, the magnetic stirring device 9 stirs evenly, and NaBH 4 React with tellurium powder for 90 minutes, the reaction equation is: Te+NaBH 4 +H 2 O→NaHTe+Na 2 B 4 o 7 +H 2 ↑, the products included in the solution after the reaction are NaHTe, NaHTe 2 B 4 o 7 and H 2 , the NaHTe content in the solution is 7.0mmol / l. If the hydrogen produced increases the pressure in the three-necked flask 1 and affects the addition of other substances, it can be decompressed by opening the discharge valve 5 .

[0041] 2) Preparation of cadmium source

[0042] The process...

Embodiment 3

[0049] 1) Preparation of tellurium source

[0050] The process is: take 90ml of water and put it into the three-neck flask 1, then add 120mg of NaBH 4 and 90 mg tellurium powder, NaBH 4 The molar ratio of tellurium powder and tellurium powder is 4.6:1, and high-purity argon gas is introduced through the feeding pipe 8 directly above the three-necked flask 1, and the air in the three-necked flask 1 is evacuated, and the magnetic stirring device 9 is evenly stirred at room temperature, and the NaBH 4 React with tellurium powder for 90 minutes, the reaction equation is: Te+NaBH 4 +H 2 O→NaHTe+Na 2 B 4 o 7 +H 2 ↑, the products included in the solution after the reaction are NaHTe, NaHTe 2 B 4 o 7 and H 2 , the NaHTe content in the solution was 3.9mmol / l. If the hydrogen produced increases the pressure in the three-necked flask 1 and affects the addition of other substances, it can be decompressed by opening the discharge valve 5 .

[0051] 2) Preparation of cadmium sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com