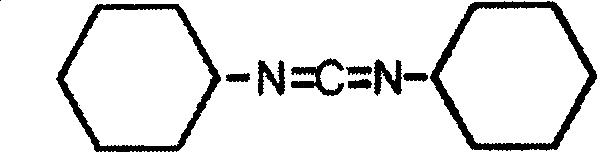

Production technique of N,N'-dicyclo hexylcar bodiimide

A dicyclohexylcarbodiimide, production process technology, applied in the field of polypeptide dehydration condensation agent N, can solve difficult desulfurization and other problems, achieve the effect of reducing production cost and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

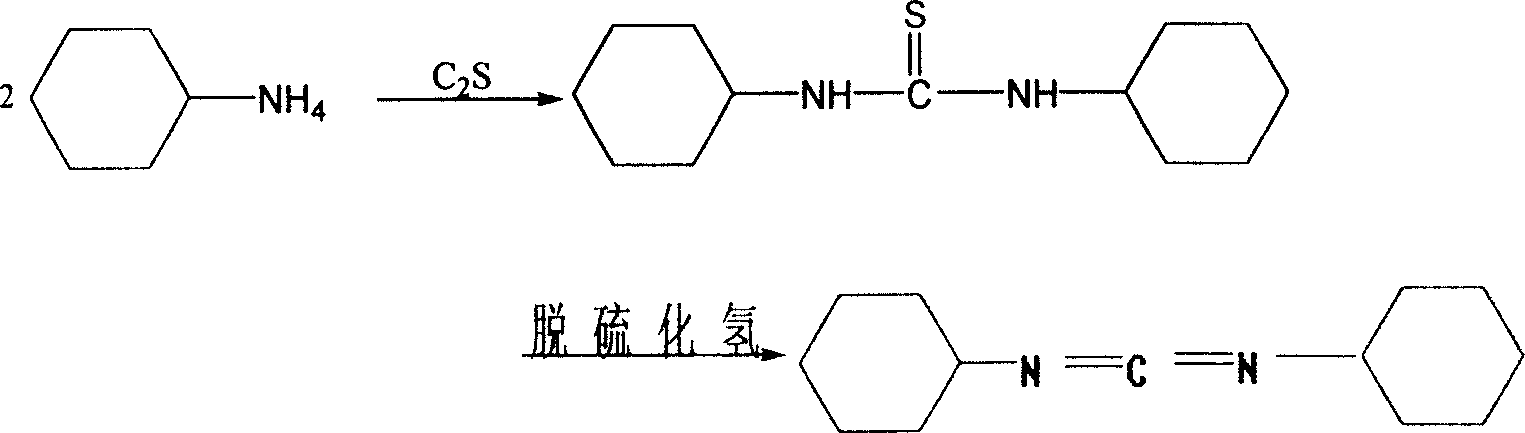

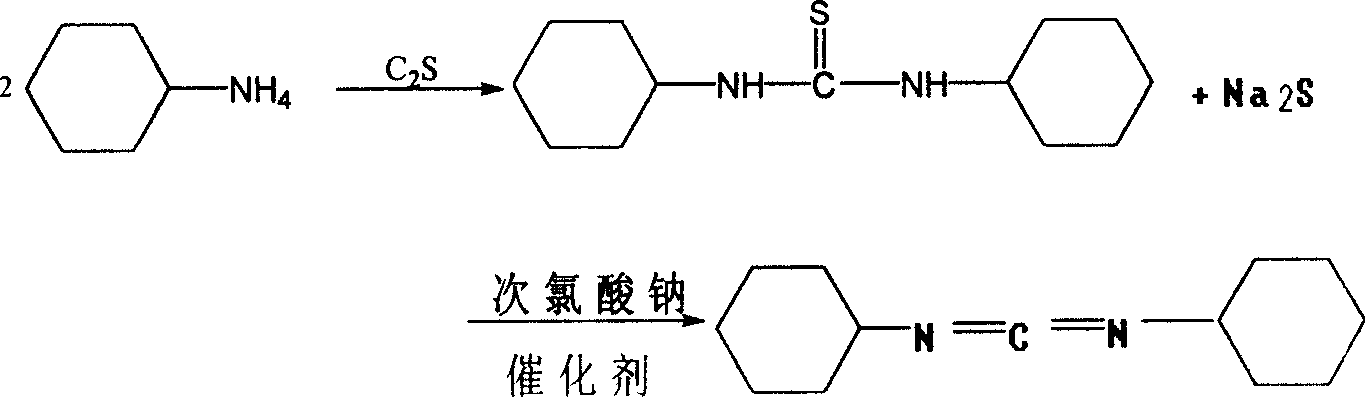

Method used

Image

Examples

Embodiment 1

[0032] Add 30g of cyclohexylamine to 200ml of xylene, stir and add 10g of carbon disulfide dropwise, control the temperature at 50°C, reflux for 3 hours, heat filter, filter out the alkali sulfide, cool down the crystal and suction filter, dry to obtain white crystal N,N-di Cyclohexylurea, yield 98%.

[0033] Add 30 g of N, N-dicyclohexylurea to 300 ml of benzene, add 1 g of catalyst (TEBA), stir and heat, add dropwise 100 ml of sodium hypochlorite solution (concentration 30%) at 70 ° C, stir for 2 hours, extract with water, and then use the same The sodium hypochlorite and catalyzer carry out secondary oxidation, and step is the same as above.

[0034] Add 20 g of the by-product sodium sulfide in the first step to the extract, under alkaline conditions, control the pH value to 9, stir and react for 2 hours, filter and extract with water separation, remove sulfur, and carry out distillation and rectification of the organic phase to obtain the product. The yield is 92%, and th...

Embodiment 2

[0036] Add 80 kg of cyclohexylamine to 400 kg of xylene, stir and add 40 kg of carbon disulfide dropwise, control the reaction temperature at 60° C., reflux for 3 hours, heat filter, filter out alkali sulfide (for standby), cool down the crystal and suction filter, and dry to obtain white crystal N. N-Dicyclohexylurea.

[0037] Add N,N-dicyclohexyl urea 700kg in 500kg benzene. Add 30 kg of catalyst polyethylene glycol, stir and heat, add dropwise 800 kg of sodium hypochlorite solution (concentration 30%) at 70 ° C, stir for 2 hours, and extract with water. Then use 800 kg of sodium hypochlorite solution (concentration 30%) and 3 kg of polyethylene glycol Secondary oxidation, the steps are the same as above.

[0038] Add 200 kg of the by-product sodium sulfide in the first step into the extract (organic phase), under alkaline conditions, control the pH value to 8, stir and react for 2 hours, filter and extract with water separation, remove sulfur, and carry out distillation an...

Embodiment 3

[0040] With embodiment 1, difference is that the consumption of catalyst TEBA is 1.5kg. The product yield is 93%, and the product purity is above 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com