Method for preparing hard alloy containing slab-shaped tungsten carbide crystal grain

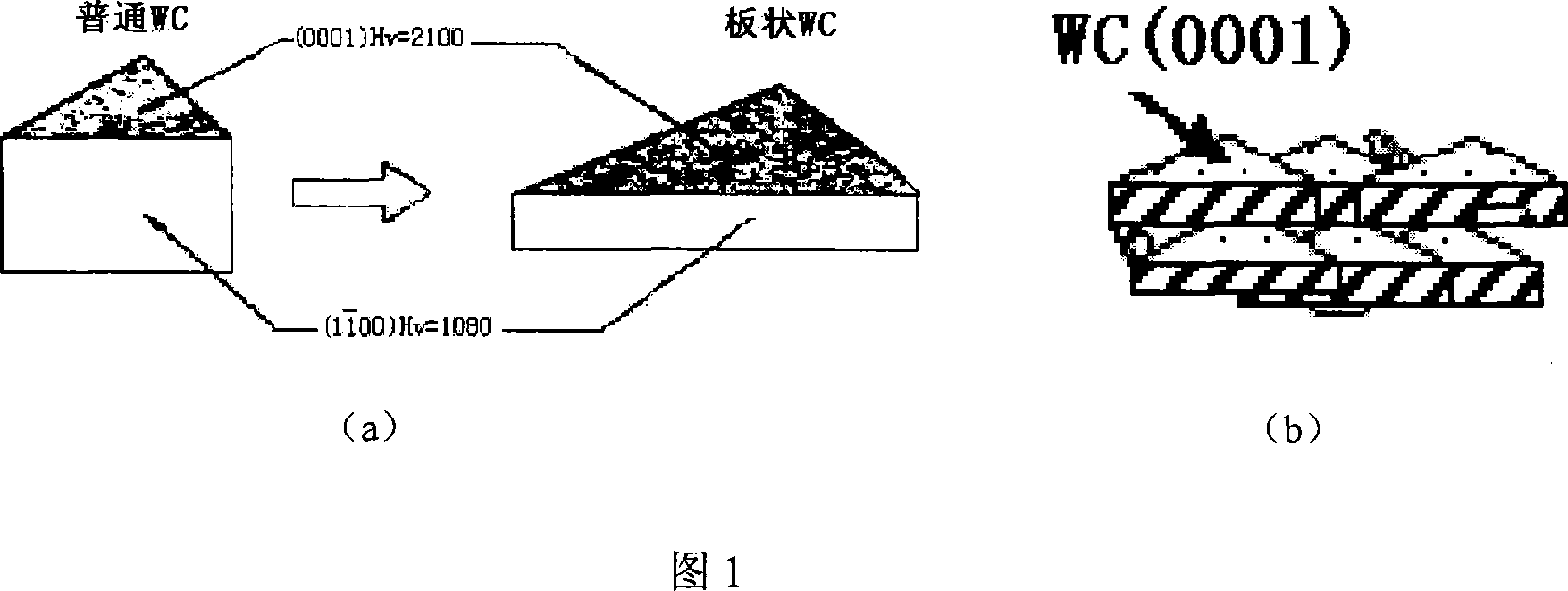

A cemented carbide, tungsten carbide single crystal technology, applied in the field of tungsten carbide cemented carbide preparation technology, can solve the problem that hardness, wear resistance, strength, toughness and fracture resistance cannot be effectively improved, the number and size of plate WC Difficult to control, damage the performance of cemented carbide and other problems, to achieve the effect of low input cost, good reproducibility and optimized performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The technological process and steps of the present embodiment are as follows:

[0024] (1) First prepare plate-shaped tungsten carbide single crystal particles as seed crystals: adopt WO with a purity of 99.5% 3 and spectroscopically pure C as raw materials, and the two are compounded at a molar ratio of 1:4, that is, WO 3 : C=1:4; after mixing it, add NaCl salt according to the ratio of salt to material 1.5:1, and use absolute ethanol as the dispersion medium, and then mix; then dry and sieve; put the above-mentioned uniformly mixed raw materials into Put it into a crucible, roast it at 1200°C in an argon atmosphere, and keep it warm at this temperature for 3 hours; the product after roasting is cooled to room temperature with the furnace; then rinse the synthesized product with distilled water three times to remove the residual molten salt particles, After drying, the plate-shaped tungsten carbide single crystal particles are obtained (for more detailed process metho...

Embodiment 2

[0029]The technological process and steps of the present embodiment are as follows:

[0030] (1) First prepare plate-shaped tungsten carbide single crystal particles as seed crystals, and its preparation method is exactly the same as the first step in the above-mentioned embodiment 1;

[0031] (2) Take a certain amount of commercial WC powder, commercial Co powder and the plate-shaped WC single crystal particles prepared above as raw materials; weigh the ingredients according to the specified weight ratio, weigh 17g of WC powder, 2g of Co powder and WC powder Seed crystal grain 1g; plate-shaped WC seed crystal grain size is 1-3μm, aspect ratio is 1:1-5:1; the above-mentioned WC powder and Co powder are put into a ball mill pot, and the ball mill medium is WC hard Alloy balls, the ball-to-material ratio is 20:1, the ball milling speed is 150 rpm, and the ball milling time is 20 hours; then add the above-mentioned plate-shaped WC seed crystal grains, and fully mix together;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com