Fast synthetic method for phosphorus-silicon-aluminum molecular sieve

A technology of SAPO-34 and synthesis method, applied in the field of molecular sieves, can solve the problems of long crystallization time, large energy consumption, and use of template agents, etc., and achieve the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A kind of rapid synthesis method of phosphorus silicon aluminum SAPO-34 molecular sieve of the present invention, concrete steps are:

[0035] a) template agent, phosphorus source, aluminum source, silicon source and water are formulated into the initial gel mixture of SAPO-34 molecular sieve in proportion;

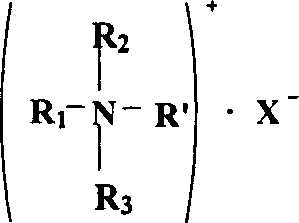

[0036] b) adding a metered organic amine accelerator to the initial gel mixture obtained in step a), and stirring to obtain a uniform initial gel mixture;

[0037] c) Put the homogeneous initial gel mixture obtained in step b) into a polytetrafluoroethylene-lined stainless steel synthesis kettle, seal it, and perform aging at room temperature to 180°C for 1 to 12 hours.

[0038] d) Further heat the aging mixture obtained in step c) to the crystallization temperature in a closed manner, and carry out constant temperature crystallization under autogenous pressure. The crystallization temperature is 180-250° C., and the crystallization time is 0.5-12 hours, preferably...

Embodiment 1

[0043] Embodiment 1 (SAPO-34 molecular sieve synthesis)

[0044] In the initial gel ratio 3.0TEA:0.6SiO 2 :P 2 o 5 : Al 2 o 3 :50H 2 O (TEA is a triethylamine template agent) Mix the measured raw materials in a certain order, stir well to form a gel, age at 80°C for 5 hours, then put it into a stainless steel autoclave lined with polytetrafluoroethylene, and heat it in a closed To 200°C, under autogenous pressure, constant temperature crystallization for 5 hours. The solid product was separated by centrifugation, washed with deionized water until neutral, and dried in air at 120°C. The XRD analysis is shown in Table 1. The synthesized product is the original powder of SAPO-34 molecular sieve.

[0045] Table 1 Example 1 synthetic sample X-ray diffraction analysis result

[0046] 2θ

[0047] 20.52

Embodiment 2

[0048] Embodiment 2 (SAPO-34 molecular sieve synthesis)

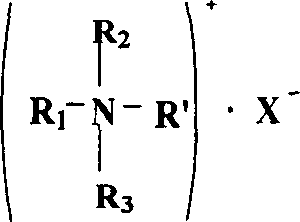

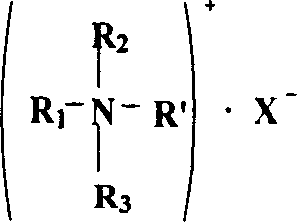

[0049] At the initial gel ratio 2.5TEA:0.6SiO 2 :P 2 o 5 : Al 2 o 3 :50H 2 O: 0.1CTAB (TEA is a triethylamine template, CTAB is hexadecyltrimethylammonium bromide) Mix the measured raw materials in a certain order, fully stir to form a gel, age at 100°C for 8 hours, and then Put it into a stainless steel autoclave lined with polytetrafluoroethylene, seal it and heat it to 180°C, and crystallize at constant temperature for 2 hours under autogenous pressure. The solid product was separated by centrifugation, washed with deionized water until neutral, and dried in air at 120°C. The XRD analysis is shown in Table 2. The synthesized product is the original powder of SAPO-34 molecular sieve.

[0050] Table 2 Example 2 synthetic sample X-ray diffraction analysis results

[0051] 2θ

[0052] 12.76

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com