Method for preparing amphipathic nature block polymer decorated nanometer-carbon tube

An amphiphilic block, carbon nanotube technology, applied in the field of materials, can solve problems such as affecting the performance of carbon nanotubes, destroying carbon nanotubes, etc., achieving good application value and avoiding complex steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

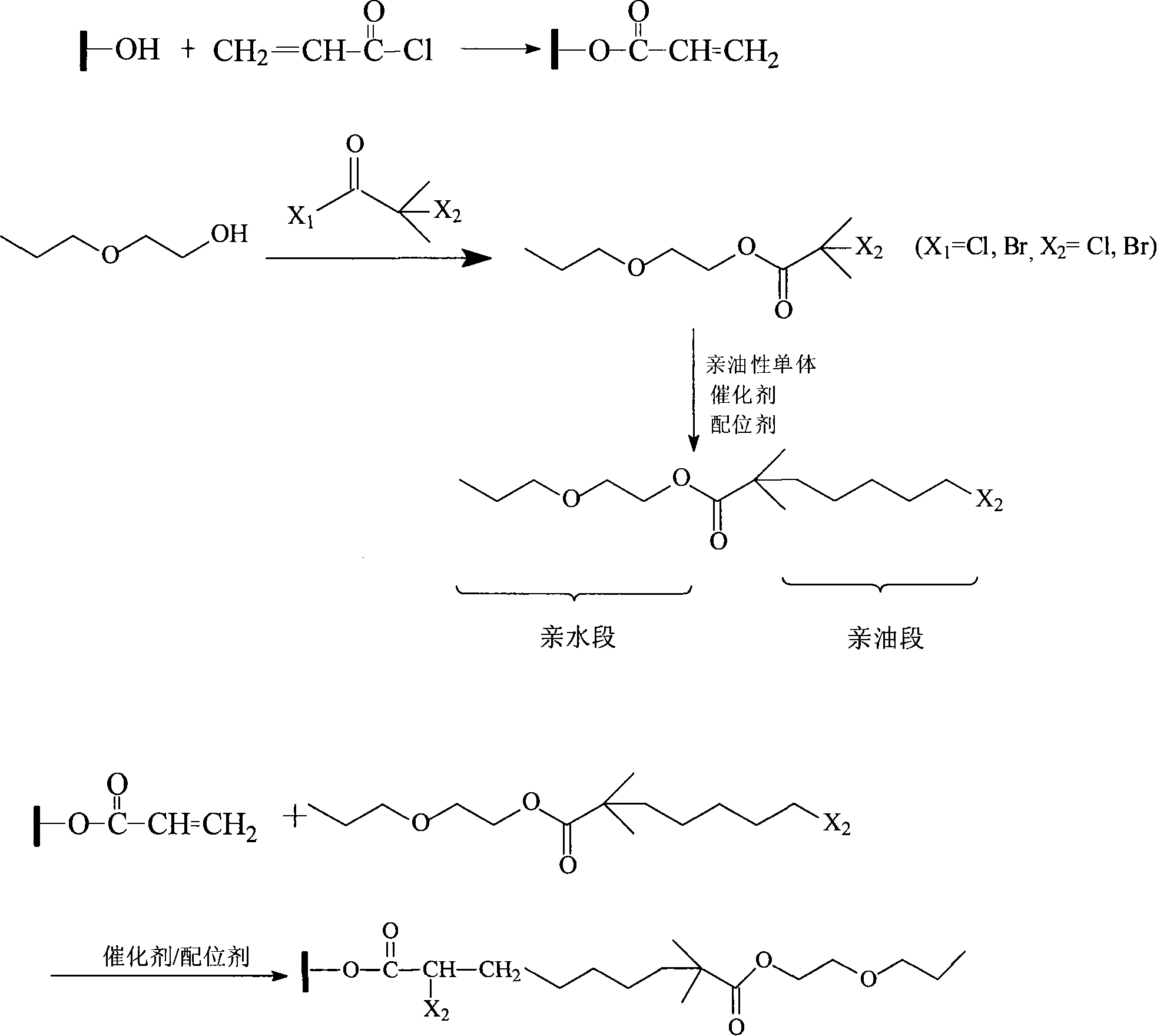

Method used

Image

Examples

Embodiment 1

[0050] MWNT-g-polyethylene glycol monomethyl ether 750 (PEG 750 ,M n =750)-b-polystyrene (PS, M n =3400) preparation

[0051] a) Preparation of vinyl functionalized multi-walled carbon nanotubes

[0052] With 100mg hydroxylated multi-walled carbon nanotubes (produced by Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, pipe diameter less than 8nm, purity ≥ 95%, directly used), 30ml acetone, 30ml chloroform and 0.5g inhibitor hydroquinone Add it into a 250ml three-neck flask, ultrasonically oscillate for 1 hour, add 5ml of acryloyl chloride, then place the flask in a 40°C constant temperature water bath, magnetically stir, condense and reflux for 24 hours, then add 25ml of absolute ethanol, and react for 3 hours. After the reaction, add 200ml Dilute the reaction solution with anhydrous ethanol, oscillate ultrasonically for 5 minutes, filter it with a polyvinylidene fluoride membrane with a pore size of 0.22 μm, and wash it repeatedly with anhydrous ethanol, a...

Embodiment 2

[0060] MWNT-g-polyethylene glycol monomethyl ether 750 (PEG 750 ,M n =750)-b-polymethyl methacrylate (PMMA, M n =4500) preparation

[0061] a) Preparation of vinyl functionalized multi-walled carbon nanotubes

[0062] With 100mg hydroxylated multi-walled carbon nanotubes (produced by Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, diameter less than 8nm, purity ≥ 95%, directly used), 1g acrylic acid, 0.12g p-toluenesulfonic acid, 0.5g p-benzoquinone and 50ml Add cyclohexanone to a 250ml three-neck flask, ultrasonically oscillate at 20°C for 2h, then place the flask in a constant temperature oil bath at 100°C, magnetically stir, condense and reflux for 18h, after the reaction is complete, add 200ml of absolute ethanol to dilute the reaction solution , after ultrasonic oscillation for 5 minutes, filter with a polyvinylidene fluoride membrane with a pore size of 0.45 μm, and wash repeatedly with absolute ethanol and deionized water, and dry the finally obtain...

Embodiment 3

[0070] SWNT-g-polyethylene glycol monomethyl ether 750 (PEG 750 ,M n =750)-b-poly tert-butyl methacrylate (PtBMA, Mn =4600) preparation

[0071] a) Preparation of vinyl-functionalized single-walled carbon nanotubes

[0072] 100mg of hydroxylated single-walled carbon nanotubes (produced by Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, diameter 0.8 ~ 1.6nm, purity ≥ 90%, used directly), 3g maleic anhydride, 0.12g p-toluenesulfonic acid, 0.5 Add g hydroquinone and 60ml cyclohexanone into a 250ml three-neck flask, ultrasonically oscillate at 25°C for 3h, then place the flask in a constant temperature oil bath at 110°C, magnetic stirring, condensing and reflux for 12h, after the reaction, add Dilute the reaction solution with 300ml of absolute ethanol, oscillate ultrasonically for 5 minutes, filter it with a polyvinylidene fluoride membrane with a pore size of 0.3 μm, and wash it repeatedly with absolute ethanol and deionized water, and dry the finally obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com