Method for preparing two-dimension single layer plumbago alkene

A single-layer graphene and catalyst technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve problems such as limitations, high raw material cost or equipment cost, unsuitable for industrial scale production, etc., and achieves easy operation and raw material cost. Inexpensive, reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

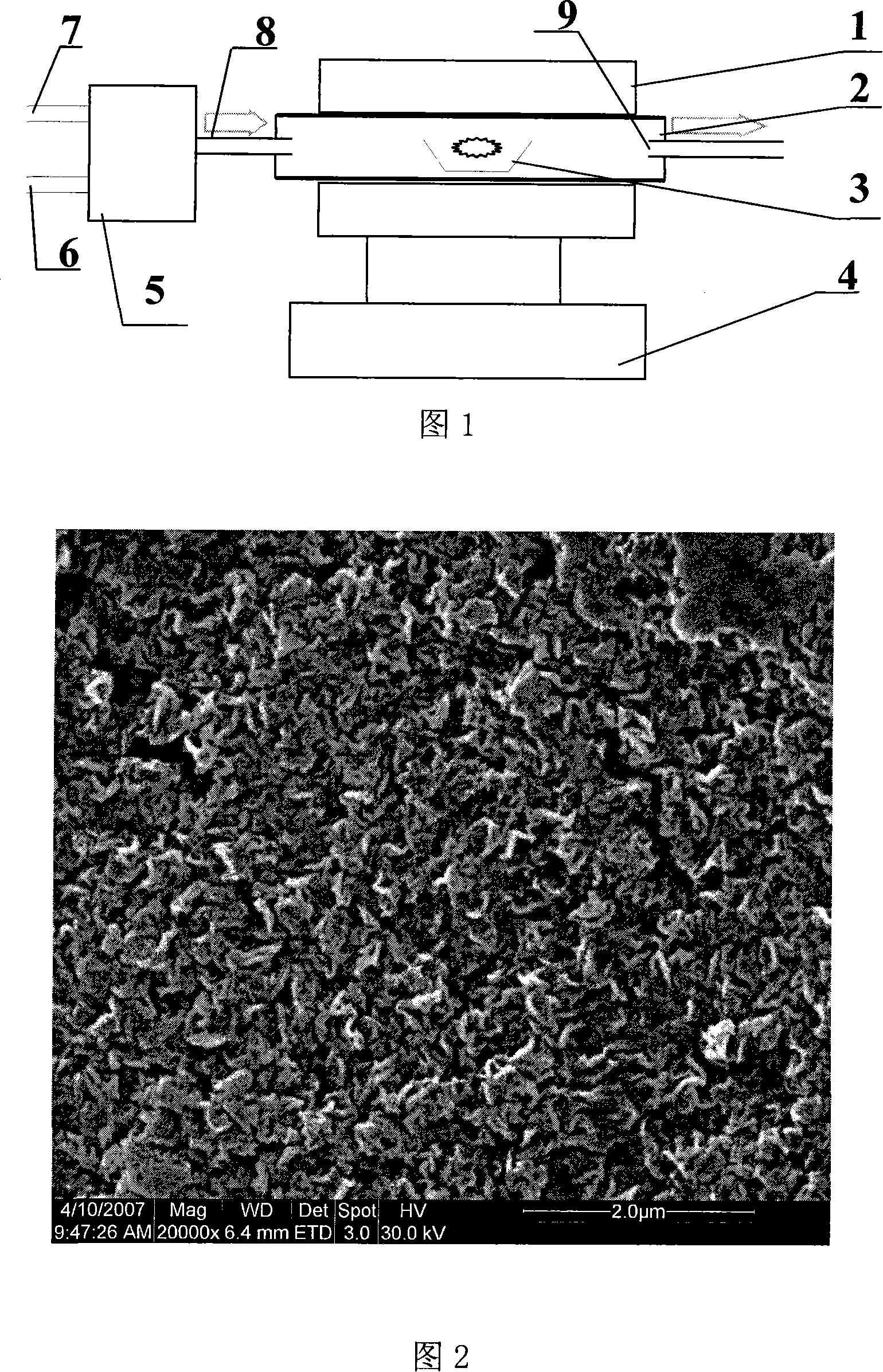

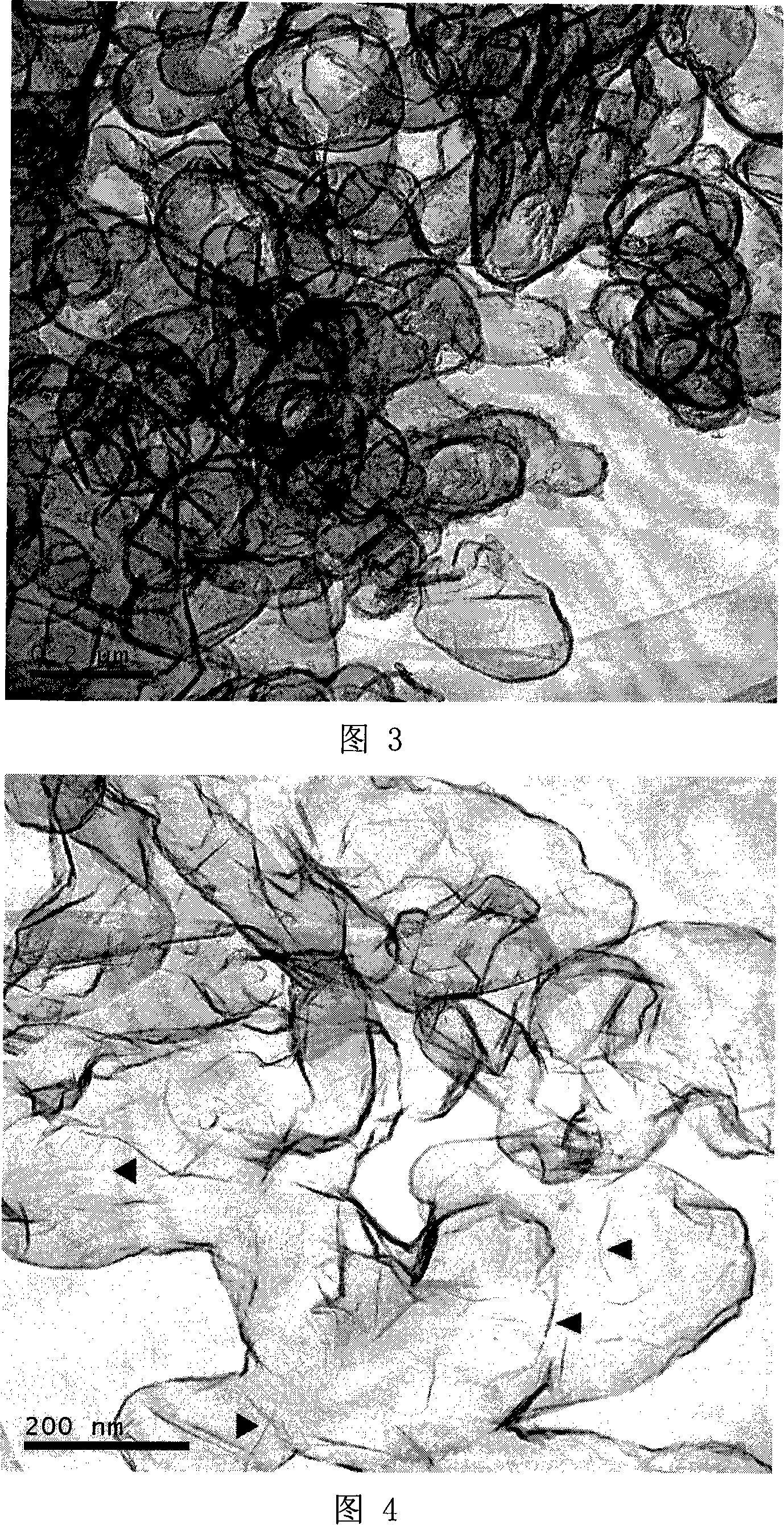

[0021] Example 1 Dispersed and dissolved 0.5 g of cobalt nitrate into 100 ml of ethanol, then added 5 g of magnesium oxide nanopowder, stirred and ultrasonicated at 40 Hz for 30 minutes, evaporated the ethanol solvent to dryness, and dried in vacuum at 100°C After 5 hours, it is finally ground into a fine powder with a particle size of 0.5-2 microns, which is the catalyst for preparing single-layer graphene. Then, put 0.5 gram of above-mentioned catalyzers into the reactor that is formed by quartz tube 2 and electric tube furnace 1 as shown in Fig. Argon gas is passed into the interior, and then the temperature of the electric furnace is raised to 850°C. After constant temperature, methane is passed into the quartz tube 2 for high-temperature cracking at a flow rate of 50 milliliters per minute. After cooling, a small-sized single-layer graphene with an area of about 0.02 square microns is prepared. The field emission scanning electron microscope photo is shown in Figure 2, ...

Embodiment 2

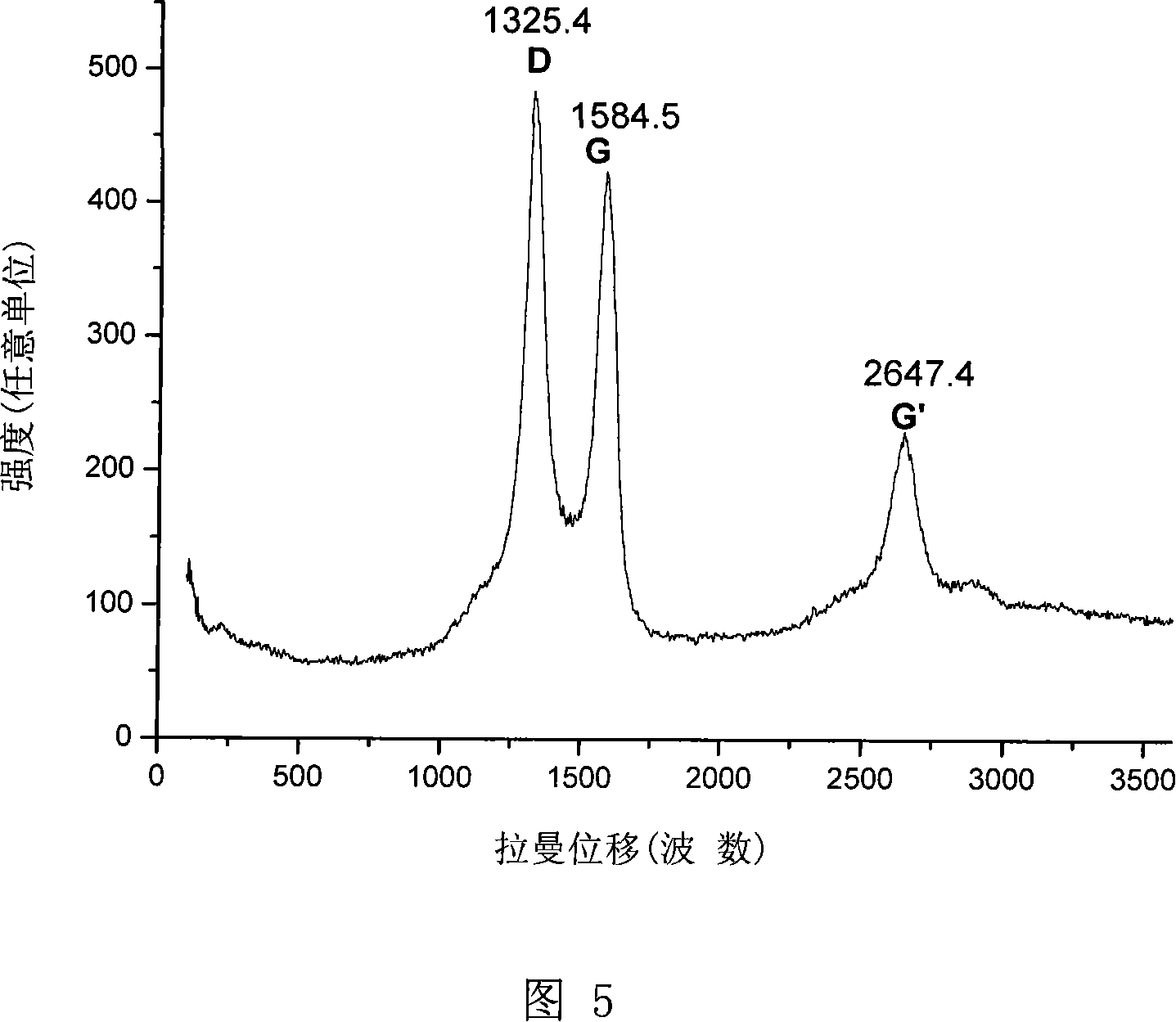

[0022] Embodiment 2 is by the preparation method of embodiment 1, just changes described cobalt nitrate into nickel nitrate, and electric furnace temperature rises to 850 DEG C and changes to rise to 1000 DEG C, obtains that the area of large piece is about 1 square micron single-layer graphene, There are some wrinkles locally, as shown in Figure 4.

Embodiment 3

[0023] Embodiment 3 is by the preparation method of embodiment 1, just changes described ethanol into acetone, and the consumption of cobalt nitrate is increased to 2 grams from 0.5 gram, and in the product obtained, except single-layer graphene, also has many multi-walled carbon nanometers Tubes and other by-products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com