A milling enriched technics for celestine ore

A celestite, enrichment technology, applied in the direction of process efficiency improvement, flotation, solid separation, etc., can solve the problems of reduced flotation speed, high sludge grade, low recovery rate, etc., to achieve easy operation control, celestite The effect of high yield and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

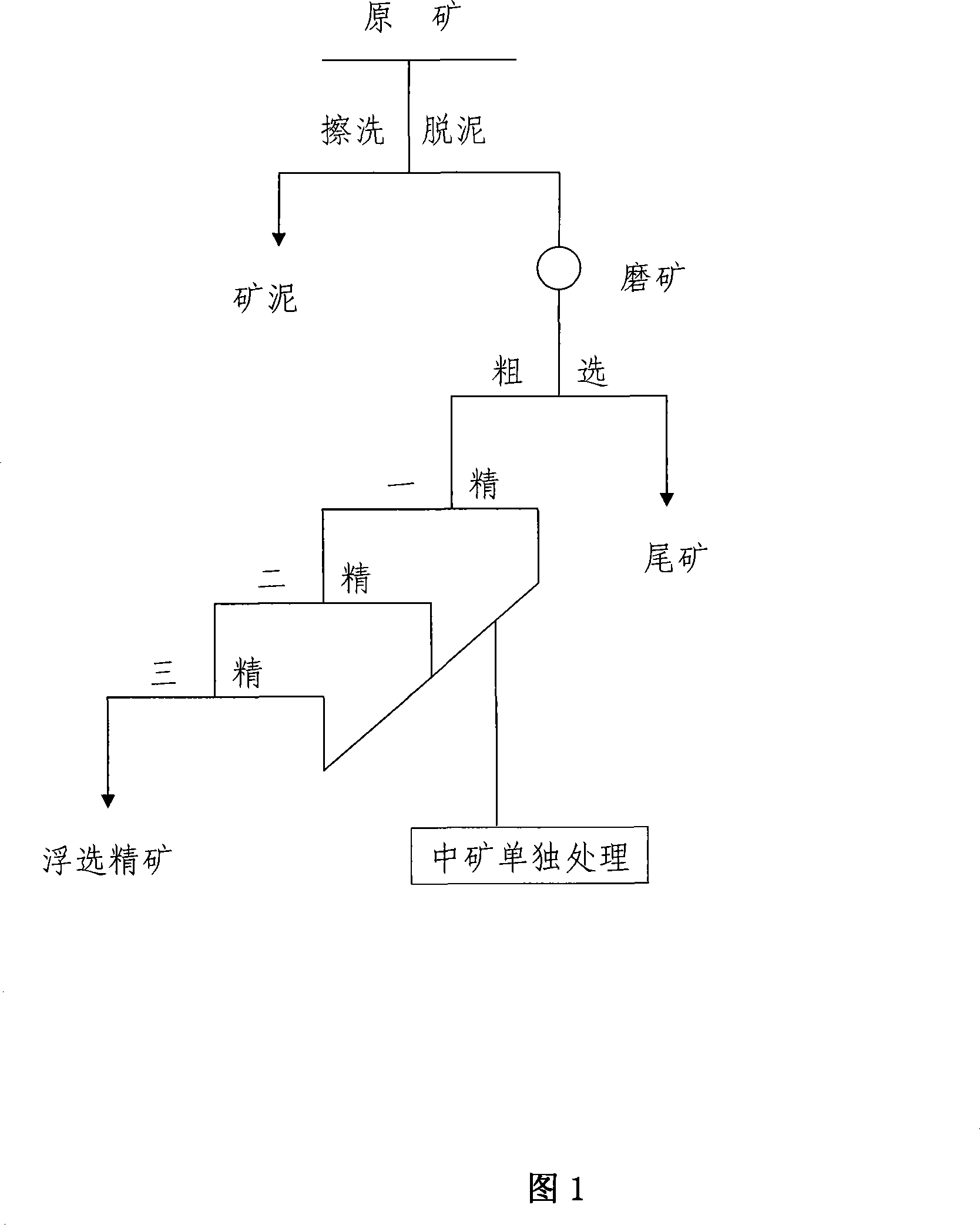

[0017] Example 1. Refer to Figure 1. A lapis lazuli beneficiation and enrichment process, the steps of which are as follows: after the lapis lazuli ore is crushed to less than 6 mm, it is sent to scrubbing and desliming equipment for desliming. The concentration of scrubbing and desliming is 40%, and the obtained slime is sent to the sludge pool After stockpiling, the obtained deslimed products enter the grinding system for grinding. The grinding concentration is 60%, so that the constituent minerals reach the basic monomer dissociation, and the slurry is adjusted to 25% of the slurry concentration, and flows into the stirring tank for chemical adjustment. Slurry, the material after pulping enters the flotation system for flotation, the product in the roughing tank is flotation tailings and is discharged and stacked, the roughing foam product is selected for 3 times, and the final selected foam product is the flotation concentrate , after concentration, filtration and drying,...

Embodiment 2

[0018] Example 2. Refer to Figure 1. A lapis lazuli beneficiation and enrichment process, the steps of which are as follows: after the lapis lazuli ore is crushed to less than 6 mm, it is sent to scrubbing and desliming equipment for desliming. The concentration of scrubbing and desliming is 50%, and the obtained slime is sent to the sludge pool After stockpiling, the obtained deslimed products enter the grinding system for grinding. The grinding concentration is 70%, so that the constituent minerals reach the basic monomer dissociation, and the slurry is adjusted to 35% of the slurry concentration, and flows into the stirring tank for chemical adjustment. Slurry, the material after pulping enters the flotation system for flotation, the product in the roughing tank is flotation tailings and is discharged and stacked, the roughing foam product is selected for 3 times, and the final selected foam product is the flotation concentrate , after concentration, filtration and drying,...

Embodiment 3

[0019] Example 3. Refer to Figure 1. A lapis lazuli beneficiation and enrichment process, the steps of which are as follows: after the lapis lazuli ore is crushed to less than 6 mm, it is sent to scrubbing and desliming equipment for desliming. The concentration of scrubbing and desliming is 45%, and the obtained slime is sent to the sludge pool After stockpiling, the obtained deslimed products enter the grinding system for grinding. The grinding concentration is 65%, so that the constituent minerals reach the basic monomer dissociation, and the slurry is adjusted to 30% of the slurry concentration, and flows into the stirring tank for chemical adjustment. Slurry, the material after pulping enters the flotation system for flotation, the product in the roughing tank is flotation tailings and is discharged and stacked, the roughing foam product is selected for 3 times, and the final selected foam product is the flotation concentrate , after concentration, filtration and drying,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com