Middle and high pressure oil-resisting rubber semiconduction shielded cable material and preparation

A technology of oil-resistant rubber and shielded cables, applied in the direction of magnetic/electric field shielding, insulated cables, cables, etc., can solve the problems of high Mooney viscosity, difficulty in fully mixing, poor workmanship, etc., and achieve high tensile strength, excellent electrical conductivity, Effect of low insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

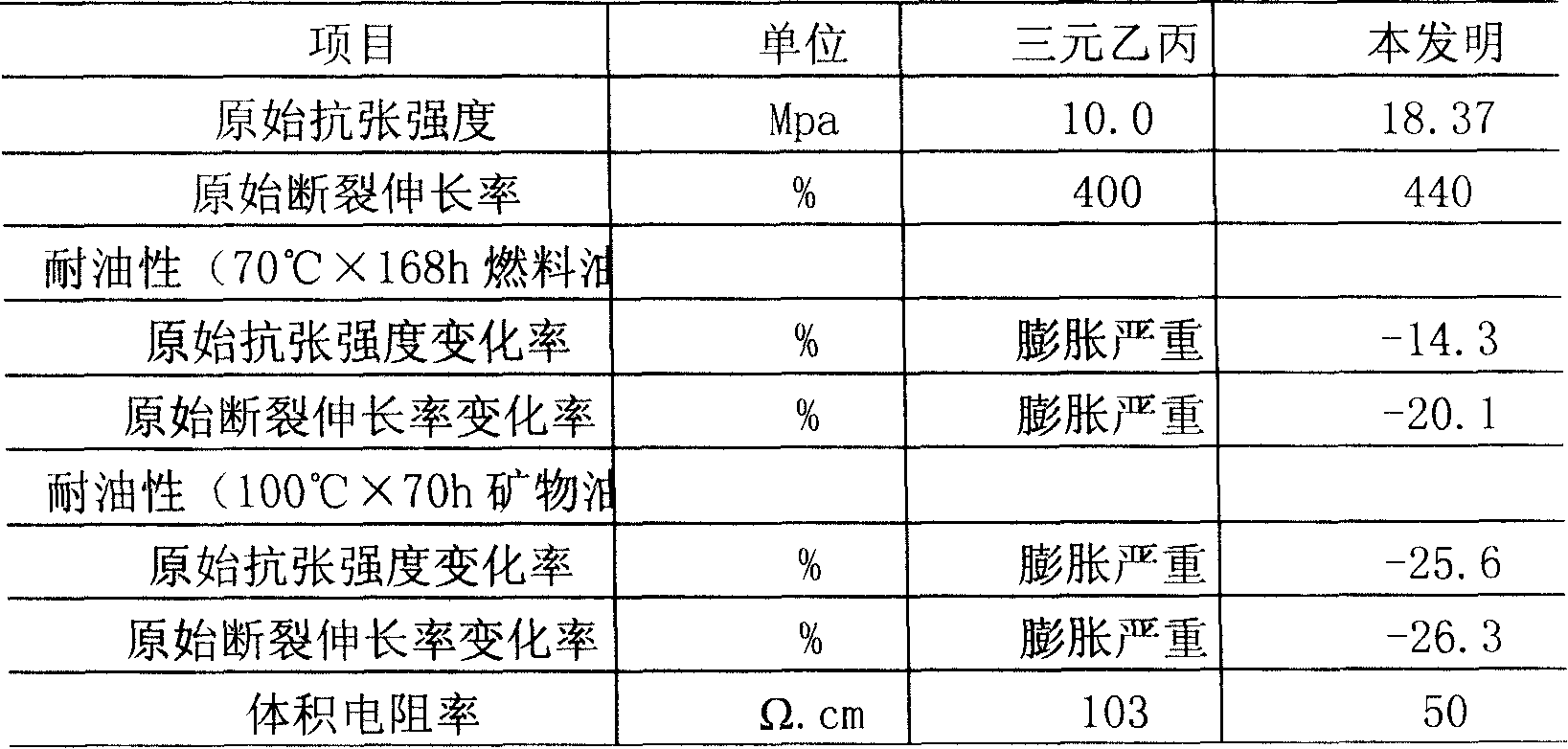

Examples

Embodiment

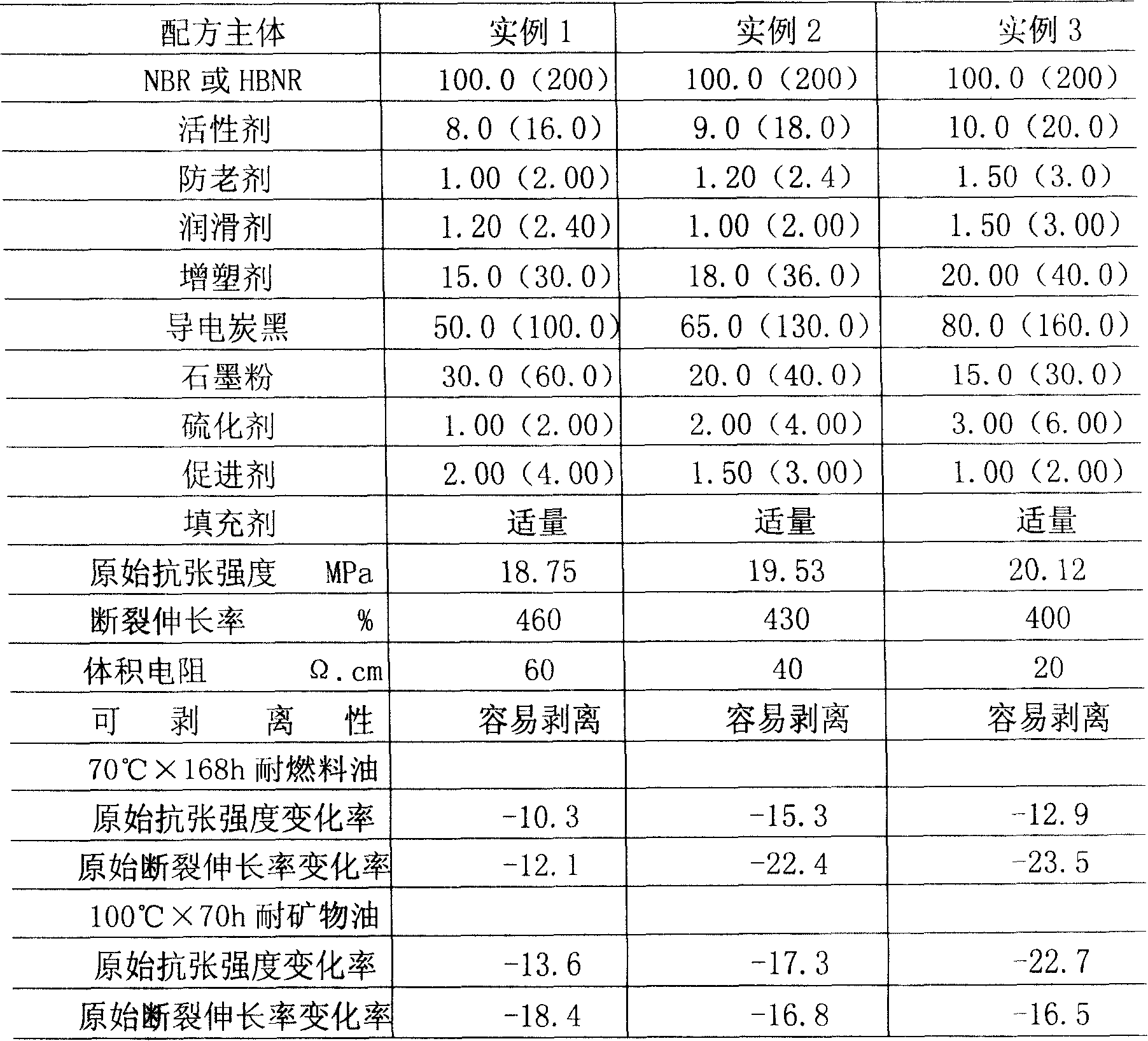

[0040]Embodiment: embodiment proportioning sees table two. Preparation, weigh each material according to the ratio of the embodiment in Table 2, first masticate the base rubber on a small open mill, the temperature of the drum is less than 60°C, masticate twice, each time masticate and stretch the thin cylinder 8-10 times, two times The second masticating interval is more than 4 hours, and the plasticity value of the rubber after masticating is 0.4-0.5. Put it aside for more than 8 hours, then knead the masticated rubber on an open mill or knead it in an internal mixer for 1-2 minutes, add conductive carbon black, graphite powder, active agent (also can be added later), and Slowly add plasticizer, lubricant, anti-aging agent and knead for 4-5 minutes. The kneading temperature is less than 90°C. Finally, add vulcanizing agent and accelerator. After kneading for 1-1.5 minutes, pull it into a thickness of 1.00mm Tablets or 4mm3 cubic grains for later use.

[0041] Take a certai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com