Method for vapour-exploding stalk enzymolysis coupling ferment for hydrogen production by using immobilized cell

A technology of immobilized cells and steam-exploded straw, which is applied in the field of fermentation technology, can solve the problems that cellulase activity is difficult to develop normally and fermentation efficiency is difficult to improve, and achieves high resistance, easy separation, and the effect of releasing product inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

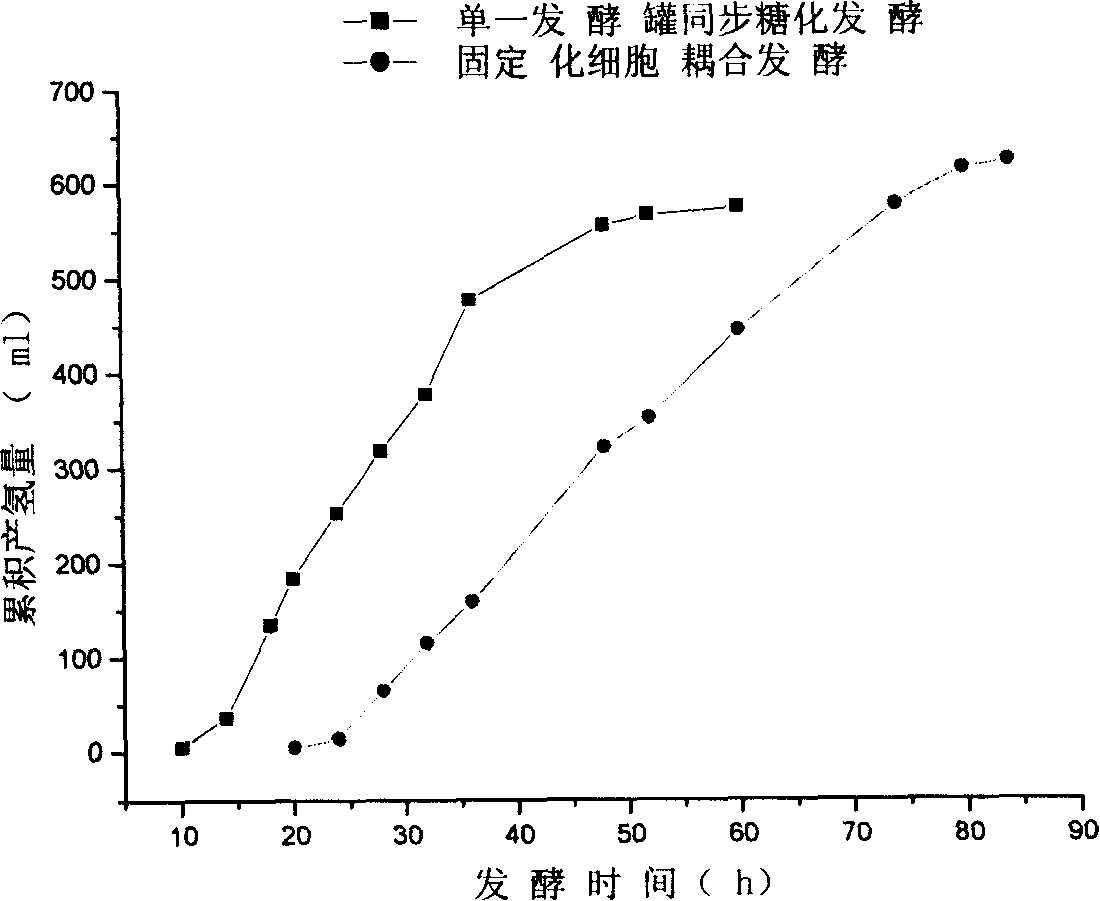

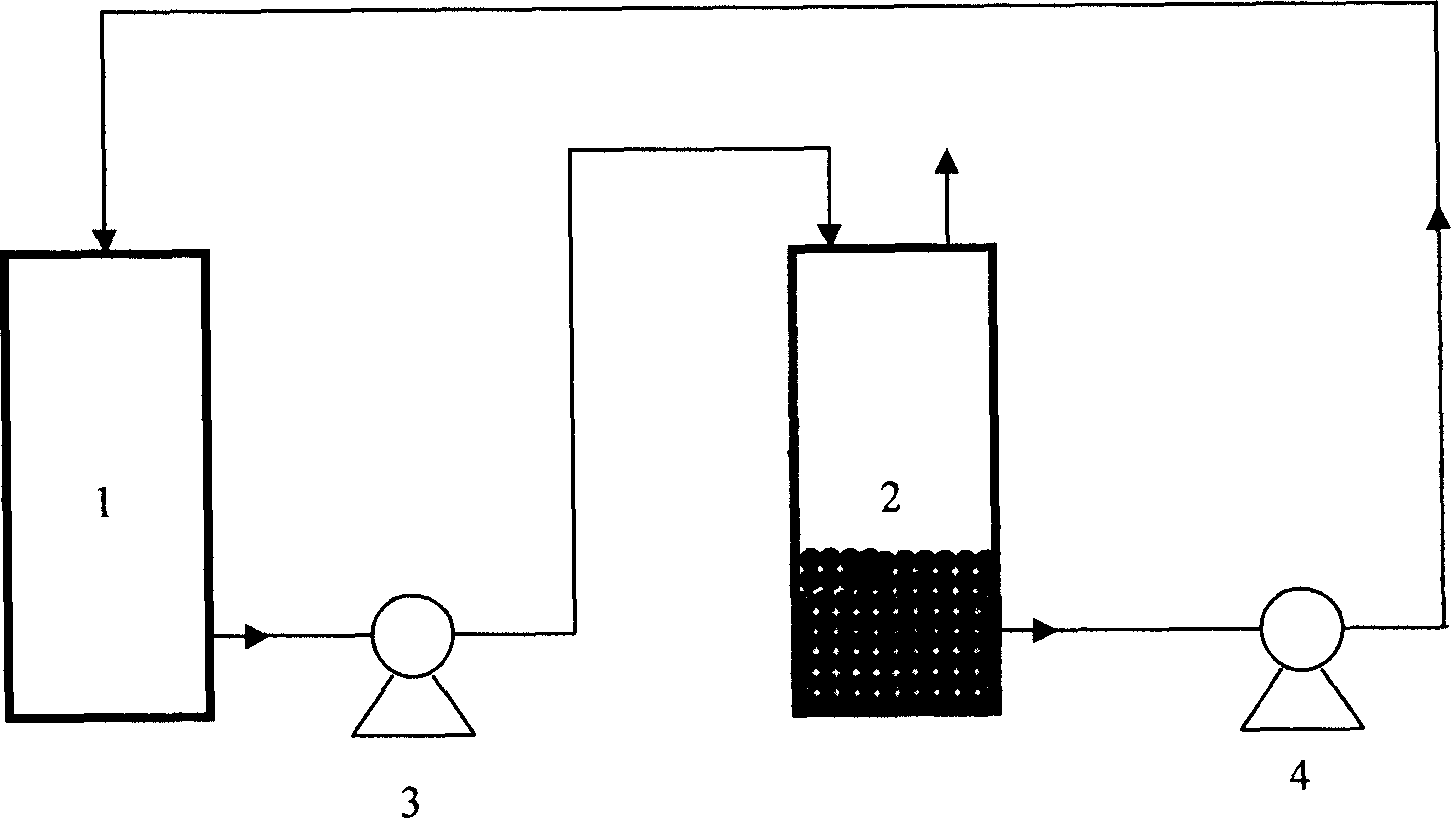

[0031] Embodiment 1. Using the method provided by the present invention to use steam-exploded corn stalks as raw material to carry out enzymatic hydrolysis coupled fermentation hydrogen production,

[0032] Specific steps are as follows:

[0033] 1. Put the raw material of steam-exploded corn stalks in an enzymolysis tank, add 25 IU / g-substrate of cellulase and tap water with pH 4.8 adjusted with sulfuric acid, the water contains urea 2g / l, KH 2 PO 4 0.51g / l, MgSO 4 0.31g / l, the solid-liquid ratio of steam-exploded straw and aqueous solution is 1:8 (w / v), enzymatically hydrolyzed at 50°C;

[0034] 2. Preparation of Clostridium butyricum (C.butylicum AS1.209) seed culture:

[0035] Each liter of seed medium includes the following components: glucose 20g, yeast extract 3g, KH 2 PO 4 0.2g, K 2 HPO 4 1.6g, MgSO 4 ·7H 2 O 0.2g, NaCl 0.1g, CaCl 2 0.01g, Na 2 S·9H 2 O 0.25g, NaMoO 4 2H 2 O 0.01g, NaHCO 3 0.2g and (NH 4 ) 2 SO 4 3.0g; Clostridium butyricum was...

Embodiment 2

[0039] Example 2. Using the method provided by the present invention to use steam-exploded wheat straw as raw material to carry out enzymatic hydrolysis coupled fermentation hydrogen production

[0040] Specific steps are as follows:

[0041] 1. Put the raw material of steam-exploded wheat straw in an enzymolysis tank, add 25IU / g-substrate of cellulase and tap water with pH 4.8 adjusted with sulfuric acid, the water contains 2g / l of yeast extract, KH 2 PO 4 0.51g / l, MgSO 4 0.31g / l, the solid-liquid ratio of steam-exploded straw and aqueous solution is 1:10 (w / v), enzymatically hydrolyzed at 50°C;

[0042] Step 2 is the same as embodiment 1;

[0043] 3. Mix the seed liquid of Clostridium butyricum (C. butyricum AS1.209) in the logarithmic growth phase with a sterile 3% sodium alginate solution, and the volume ratio of the seed liquid to the sodium alginate solution is 1:4. Use a sterile syringe to draw the mixture, slowly drop the mixture into sterile 0.05mol / l CaCl 2 so...

Embodiment 3

[0046] Example 3. Using the method provided by the present invention to use steam-exploded rice straw as raw material to carry out enzymatic hydrolysis coupled fermentation hydrogen production, the specific steps are as follows:

[0047] 1. Put the raw material of steam-exploded rice straw in an enzymolysis tank, add 25 IU / g-substrate of cellulase and tap water with pH 4.8 adjusted with sulfuric acid, the water contains urea 2g / l, KH 2 PO 4 0.51g / l, MgSO 4 0.31h / l, the solid-liquid ratio of the steam-exploded straw and the aqueous solution is 1:12 (w / v), and the enzyme is hydrolyzed at 50°C.

[0048] Step 2 is the same as in Example 1.

[0049] 3. Mix the seed liquid of Clostridium butyricum (C. butyricum AS1.209) in the logarithmic growth phase with a sterile 4% sodium alginate solution, and the volume ratio of the seed liquid to the sodium alginate solution is 1:5. Use a sterile syringe to draw the mixture, slowly drop the mixture into sterile 0.05mol / l CaCl 2 solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com