Separator for lithium ion secondary battery and lithium ion secondary battery

A secondary battery and lithium ion technology, applied in the direction of secondary batteries, battery electrodes, battery components, etc., can solve the problems of difficult to form electrode/separator interface, difficult to form holes continuously, impractical, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] PET staple fibers with a fineness of 0.11dtex (average fiber diameter about 3.2μm) were bonded with PET staple fibers with a fineness of 0.33dtex (average fiber diameter about 5.5μm) and PET staple fibers with a fineness of 0.22dtex (average fiber diameter about 4.5μm). Mixture with PET staple fiber, blending with the weight ratio of 3 / 2 / 5, by wet papermaking method with a basis weight of 12.6g / m 2 A film was formed and calendered at 140° C. to obtain a PET nonwoven fabric with a film thickness of 18 μm.

[0085] Polym-phenylene isophthalamide (manufactured by Teijin Technology Corporation, trade name "Conex") was dissolved in a mixed solvent of dimethylacetamide:tripropylene glycol=85:15 (weight ratio) The concentration was 9% by weight, and a polymer solution was prepared. Apply the polymer solution to both sides of the PET nonwoven fabric, and immerse the coated material in a 30° C. coagulation bath composed of dimethylacetamide:water=55:45 (weight ratio) for 60 sec...

Embodiment 2

[0088] Use polym-phenylene isophthalamide short fibers with a fineness of 0.9dtex (average fiber diameter about 10μm), and use a dry method with a basis weight of 15.0g / m 2 A film was formed and calendered at 320° C. to obtain a nonwoven fabric with a film thickness of 30 μm.

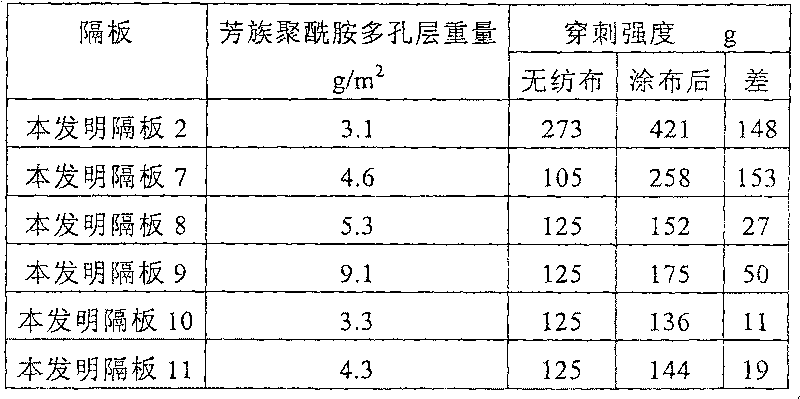

[0089]Using this nonwoven fabric and the same polymer solution as in Example 1, the separator for lithium ion secondary batteries of the present invention was obtained in the same manner. This separator is referred to as the separator 2 of the present invention. The film thickness of the separator 2 of the present invention is 34 μm, and the basis weight is 18.1 g / m 2 , Gurley value (JIS P8117) is 35 seconds / 100cc.

Embodiment 3

[0102] Lithium cobaltate (LiCoO 2 ; Nippon Chemical Industry Co., Ltd.) powder 89.5 parts by weight, 4.5 parts by weight of acetylene black and 6 parts by weight of polyvinylidene fluoride were kneaded to prepare a slurry. The obtained slurry was coated on an aluminum foil with a thickness of 20 μm, dried and then pressed to obtain a positive electrode with a thickness of 100 μm.

[0103] A slurry was prepared by kneading 87 parts by weight of mesocarbon microspheres (MCMB: manufactured by Osaka Gas Chemical Co., Ltd.) powder, 3 parts by weight of acetylene black, and 10 parts by weight of polyvinylidene fluoride using N-methyl-2-pyrrolidone solvent. . The obtained slurry was coated on a copper foil having a thickness of 18 μm, dried and then pressed to obtain a negative electrode of 90 μm.

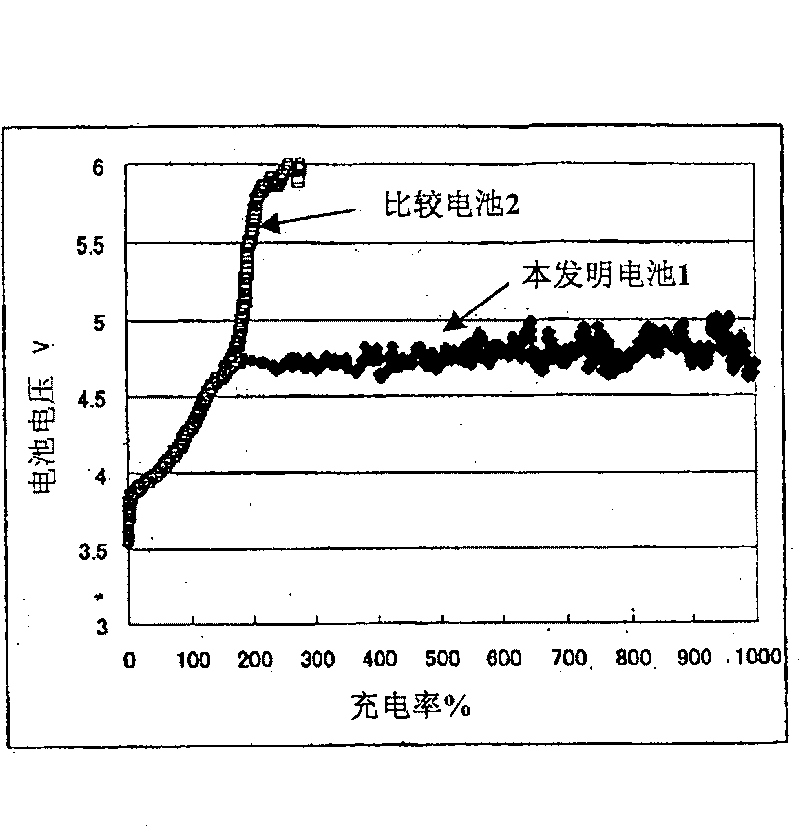

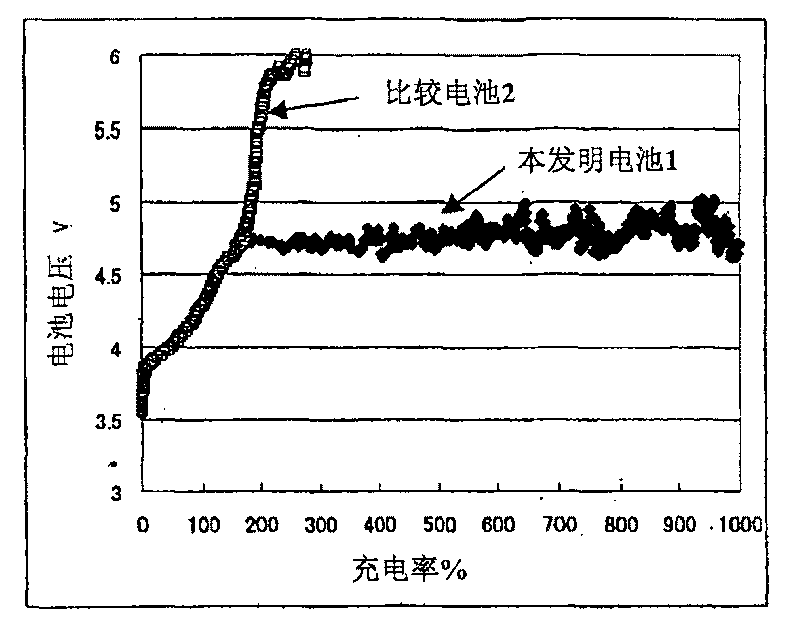

[0104] The above-mentioned positive electrode and negative electrode were opposed to each other with the separator 1 of the present invention produced in Example 1 interposed therebetwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Gurley value | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com