High-effective composite filter aid for sludge dehydration and method of use thereof

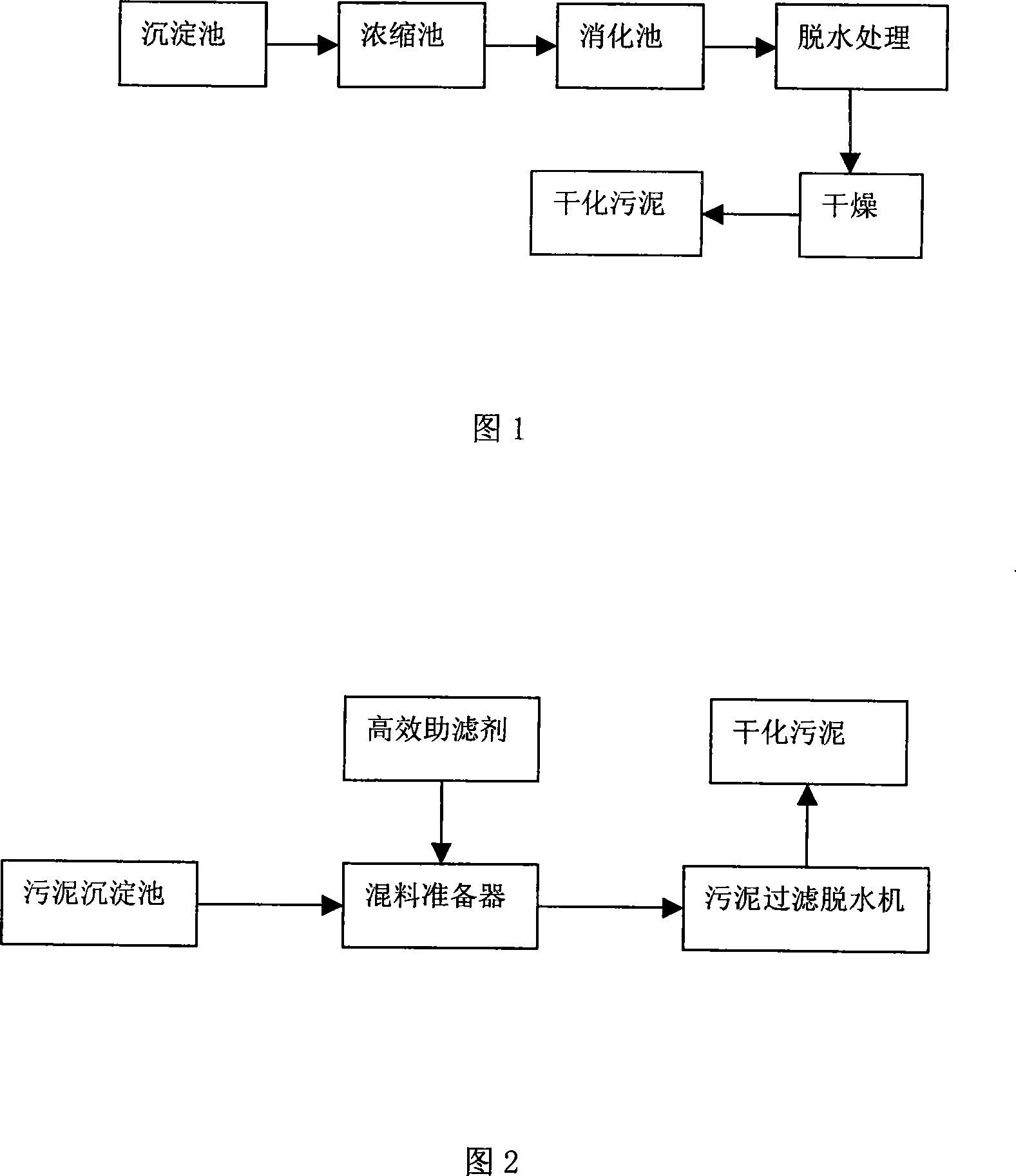

A sludge dehydration and filter aid technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of reducing to about 70%, secondary pollution, complex process, etc., to achieve improved dehydration performance, no secondary Pollution, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The sludge without adding high-efficiency composite filter aid was dehydrated by a belt filter press with a moisture content of 77.8% and a specific resistance of 2.0×10 13 m / kg.

[0030] Add 2% high-efficiency composite filter aid (Al 2 o 3 30%, SiO 2 55%, CaO 2%, bentonite 3%, iron powder 10%), stir evenly to destabilize the sludge. Adjust the sludge supply of the sludge pump, the filter belt speed is 2m / min, and the dehydration tension is 0.3MPa. The washing quality of the filter belt has a great influence on the dehydration effect, and the pressure of the washing water selected in the present invention is 0.7MPa. After dehydration, the moisture content of the sludge is 48%, and the specific resistance is 0.6×10 11 m / kg.

Embodiment 2

[0032] The moisture content of the sludge without adding high-efficiency composite filter aid is 76.5% after dehydration with a centrifugal dehydrator, and the specific resistance is 1.7×10 13 m / kg.

[0033] Add 5% high-efficiency composite filter aid (Al 2 o 3 20%, SiO 2 55%, CaO 8%, bentonite 13%, iron powder 4%), using a centrifugal dehydrator, the centrifuge speed is 2800rpm, and the speed difference is 13rpm. After being dehydrated by a centrifugal dehydrator, the moisture content is 49.5%, and the specific resistance is 0.71×10 11 m / kg.

Embodiment 3

[0035] The moisture content of the sludge without adding high-efficiency composite filter aid is 79.3% after dehydration with a plate and frame filter press, and the specific resistance is 2.1×10 13 m / kg.

[0036] Add 6% high-efficiency composite filter aid (Al 2 o 3 30%, SiO 2 40%, CaO 8%, bentonite 12%, iron powder 10%), using a plate and frame filter press for dehydration, the pressure is 1.2MPa. μXL (distributed control) system. The sludge discharge tank, lifting pump room, thickening tank, dehydration machine room equipment and instrument status are all manually operated and monitored by the CRT (industrial control system) operating station. After dehydration, the moisture content of the sludge is 49.6%, and the specific resistance is 0.89×10 11 m / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific resistance | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com