Method for manufacturing glass-ceramics

A manufacturing method and technology for glass-ceramic, applied in glass production and other directions, can solve the problems of secondary pollution and high production cost, and achieve the effects of eliminating pollution, shortening processing time, and reducing tax

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

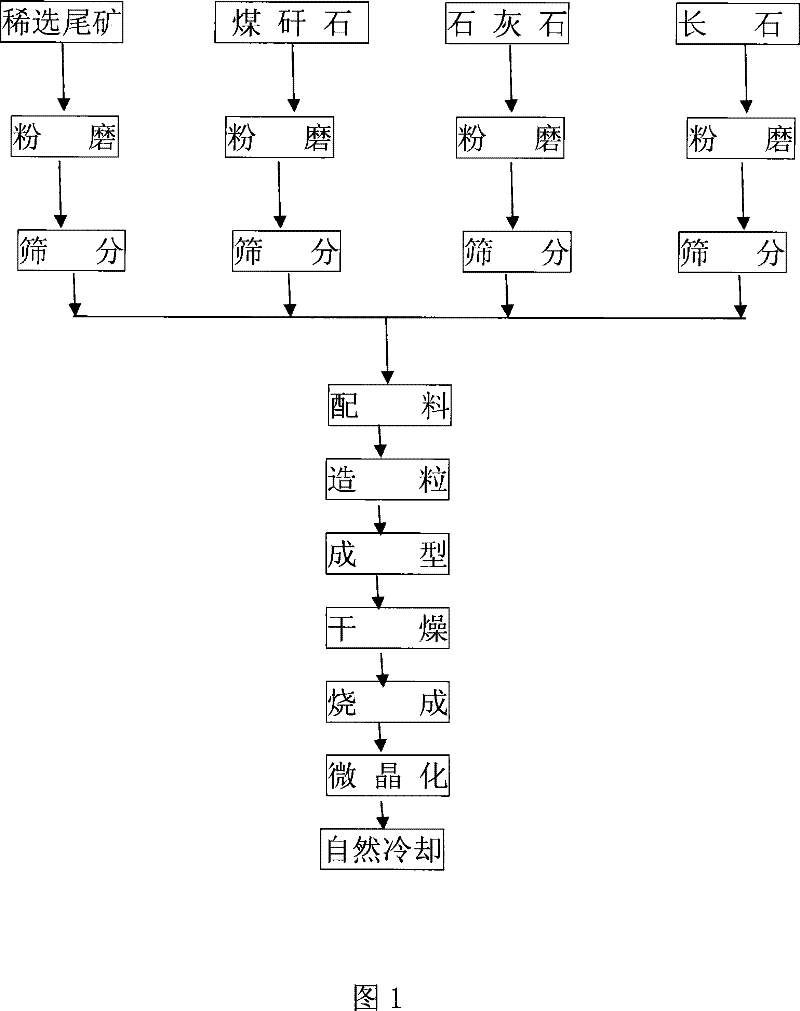

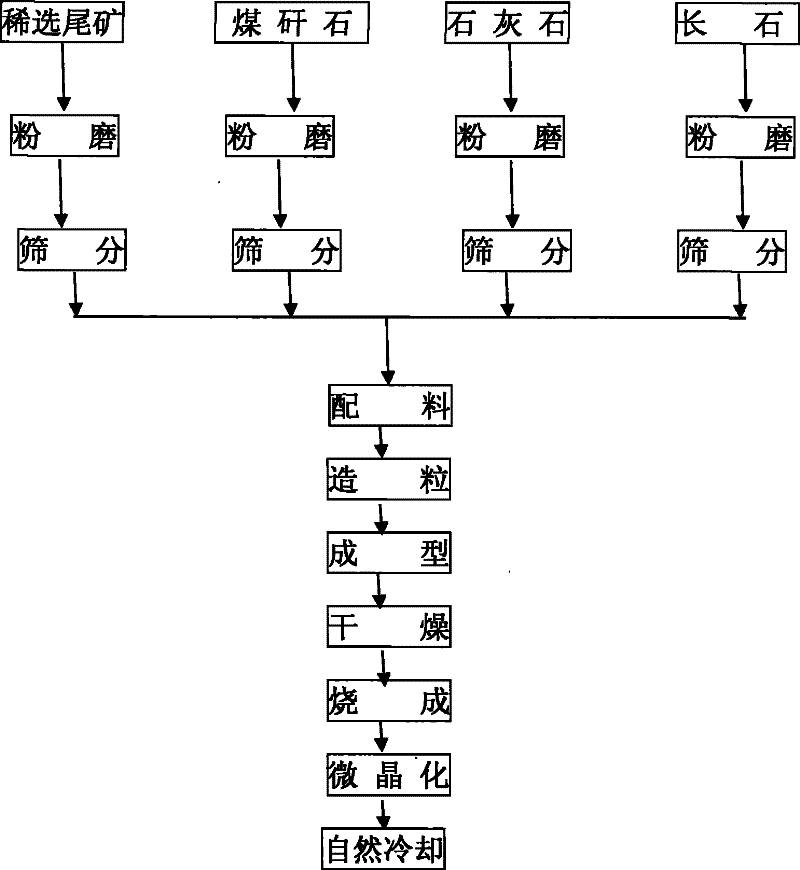

[0025] For its process, see figure 1 ,

[0026] 1. Powder preparation

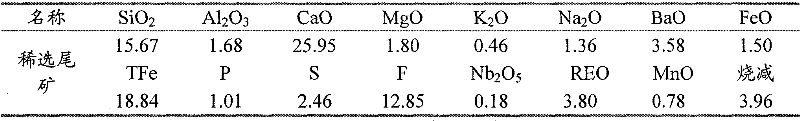

[0027] The rare earth tailings used were taken from Baotou Steel Rare Earth Plant. The chemical composition of rare earth tailings is shown in Table 1; the chemical composition of coal gangue is shown in Table 2; the chemical composition of feldspar is shown in Table 3. Weigh the rare earth tailings, coal gangue, and feldspar according to the ratio of raw materials:balls 1:2, and put them into ball milling tanks (the total volume of the materials should be less than 2 / 3 of the volume of the ball milling tank), and ball mill for 24 hours.

[0028] 2. Screening

[0029] The rare earth tailings powder, coal gangue, and feldspar powder raw materials after ball milling are respectively passed through a 325-mesh sieve, and the prepared powder is put into a powder bag for later use.

[0030] 3. Ingredients

[0031] Rare earth tailings powder: feldspar: coal gangue were weighed in a weight ratio of 100:48:12, ...

Embodiment 2

[0042] For its process, see figure 1 ,

[0043] 1. Powder preparation

[0044] The rare earth tailings used were taken from Baotou Steel Rare Earth Plant. The chemical composition of rare earth tailings is shown in Table 1; the chemical composition of coal gangue is shown in Table 2; the chemical composition of feldspar is shown in Table 3. Weigh the rare earth tailings, coal gangue, and feldspar according to the ratio of raw materials:balls 1:2, and put them into ball milling tanks (the total volume of the materials should be less than 2 / 3 of the volume of the ball milling tank), and ball mill for 24 hours.

[0045] 2. Screening

[0046] The rare earth tailings powder, coal gangue, and feldspar powder raw materials after ball milling are respectively passed through a 325-mesh sieve, and the prepared powder is put into a powder bag for later use.

[0047] 3. Ingredients

[0048] Rare earth tailings powder: feldspar: coal gangue were weighed in a weight ratio of 100:26:17, ...

Embodiment 3

[0059] For its process, see figure 1 ,

[0060] 1. Powder preparation

[0061] The rare earth tailings used were taken from Baotou Steel Rare Earth Plant. The chemical composition of rare earth tailings is shown in Table 1; the chemical composition of coal gangue is shown in Table 2; the chemical composition of feldspar is shown in Table 3; the chemical composition of limestone is shown in Table 4. Weigh the rare earth tailings, coal gangue, feldspar, and limestone according to the ratio of raw materials:balls 1:2, and put them into ball milling tanks (the total volume of the materials should be less than 2 / 3 of the volume of the ball milling tank), and mill for 24 hours.

[0062] 2. Screening

[0063] After the ball milling, the rare earth tailings powder, limestone, coal gangue, and feldspar powder raw materials are respectively passed through a 325-mesh sieve, and the prepared powder is put into a powder bag for later use.

[0064] 3. Ingredients

[0065] Weigh rare ear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com