High-capacity dewatering electric charge inducing color chromatogram medium and preparation method

A chromatographic medium and hydrophobic electricity technology, applied in the field of biochemical engineering, can solve the problems of low adsorption capacity and harsh elution conditions of hydrophobic charge-induced chromatography, and achieve the effect of ensuring activity, good stability and convenient regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Rinse the Sepharose CL-6B soaked in 20% ethanol with an average particle size of 87 μm with deionized water, and drain it with a water pump in an hour glass for 5 minutes; weigh 1 g of the drained Sepharose CL-6B and set Into a 50ml Erlenmeyer flask, add 1.5mL sodium hydroxide (0.8mol / L), 0.5mL epichlorohydrin, 2mL dimethyl sulfoxide, shake and react at 40°C and 170rpm for 3h. The epoxy-activated Sepharose CL-6B agarose gel medium can be obtained. After the activation medium was washed repeatedly in the hourglass to remove free epichlorohydrin, the epoxy modification density of the gel medium was determined to be 120 μmol / mL of the activation medium.

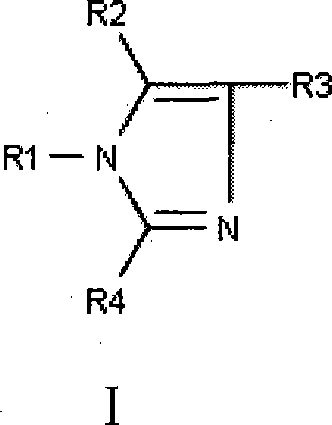

[0025] Weigh 1.0 g of the activation medium and place it in 5 mL of disodium hydrogen phosphate, which contains 0.6 mmol of histamine; place it in a constant temperature water bath at 60°C for 10 hours; After thoroughly rinsing with % ethanol and distilled water, add 0.5g / L sodium borohydride solution to reduce the epoxy...

Embodiment 2

[0027] The volumetric dosage of epichlorohydrin in embodiment 1 is 1.5mL, the volumetric dosage of 1.4mol / L sodium hydroxide is 5.0mL, other conditions are constant, and the epoxy group modification density in the obtained activation medium is 158.6 μ mol / mL activation medium. The concentration of 3-methylhistamine added to the coupling reaction was 2.0 mmol / L, and the coupling density of the ligand in the chromatographic medium was 114 μmol / mL.

Embodiment 3

[0029] Rinse the Sepharose CL-6B soaked in 20% ethanol with an average particle size of 87 μm with deionized water, and drain it with a water pump in an hour glass for 5 minutes; weigh 1 g of the drained Sepharose CL-6B and set Into a 50mL Erlenmeyer flask, add 1.5mL sodium hydroxide (0.5mol / L), 0.3mL epichlorohydrin, 2mL dimethyl sulfoxide, shake and react at 25°C and 170rpm for 3h. The epoxy-activated Sepharose CL-6B agarose gel medium can be obtained. After the activation medium was washed repeatedly in the hourglass to remove free epichlorohydrin, the epoxy modification density of the gel medium was determined to be 70 μmol / mL of the activation medium.

[0030] Weigh 1.0 g of the activation medium and place it in 5 mL of disodium hydrogen phosphate, the solution contains 0.5 mmol 4-aminomethylimidazole; place it in a constant temperature water bath at 60°C for 10 hours; , volume concentration 20% ethanol and distilled water, after thoroughly rinsing, add 0.5g / L sodium bor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com