Solid base catalyst for biological diesel oil synthesis, preparation method and uses thereof

A solid base catalyst, biodiesel technology, applied in the preparation of liquid hydrocarbon mixtures, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of prolonged reaction time, complex preparation process, catalytic Ineffective and other problems, to achieve the effect of high catalytic efficiency, simple equipment, rich raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

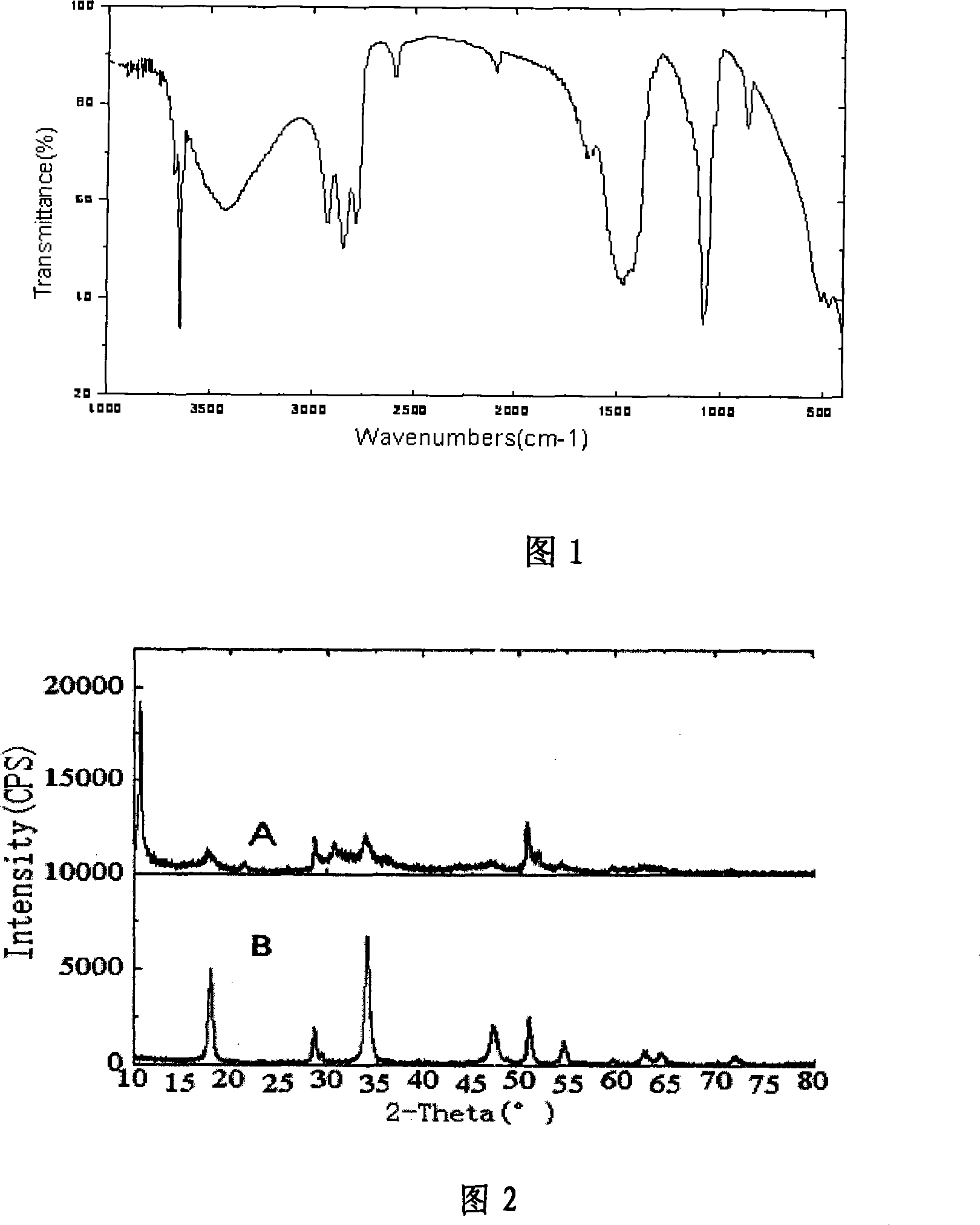

Image

Examples

Embodiment 1

[0028] Weigh CaO 10g, (NH 4 ) 2 CO 3 25g into an 800ml beaker, add 200ml of water, add 2g of emulsifier (Tween), put it in a cold water bath to cool, and stir at high speed for 1 hour at the same time to generate CaCO 3 . Suction filter the prepared calcium carbonate, then put it into an oven to dry, keep it at 105°C for 2 hours, grind it until it is completely dry, put it into a desiccator and save it for later use. Weigh 1.786gCaCO 3 In a crucible, heat up to 900°C in a high-temperature resistance furnace, calcinate for 2 hours, cool down to 650°C, take it out and cool it with anhydrous methanol to prepare the catalyst.

[0029] With 50g soybean oil (density is 0.92g / cm 3 ), 1g of the above catalyst and 21.5ml of methanol (density 0.792g / cm 3 ) mixed solution was put into a 250ml triangular grinding neck flask, placed on a constant temperature magnetic stirrer, stirred and heated to 67-68°C, and after 2 hours of reaction, the stirring and heating were stopped. Move t...

Embodiment 2

[0031] Weigh 3 g of calcium carbonate reagent (analytically pure) in a crucible, heat up to 900°C in a high-temperature resistance furnace, calcinate for 2 hours, cool down to 650°C, take it out and cool it with anhydrous methanol to prepare the catalyst.

[0032] With 50g soybean oil (density is 0.92g / cm 3 ), 1g of the above catalyst and 21.5ml of methanol (density 0.792g / cm 3 ) mixed solution was put into a 250ml triangular grinding neck flask, placed on a constant temperature magnetic stirrer, stirred and heated to 67-68°C, and after 2 hours of reaction, the stirring and heating were stopped. Move the reaction solution to a centrifuge to separate the catalyst, then pour it into a separatory funnel, let it stand, and separate it into upper and lower layers. After methanol was distilled off in the upper layer water bath, the conversion rate was measured to be 95.6%.

Embodiment 3

[0034] Weigh Ca(Ac) 2 40g, (NH4) 2 CO 3 30g into an 800ml beaker, add 300ml of water, add 3g of emulsifier (Tween), put it in a cold water bath to cool, and stir at high speed for 1 hour at the same time to generate CaCO 3 . The prepared calcium carbonate was suction filtered, then dried in an oven, kept at 105°C for 2 hours, ground into fine pieces after drying, and stored in a desiccator for later use. Weigh 1.786gCaCO 3 In a crucible, heat up to 900°C in a high-temperature resistance furnace, calcinate for 2 hours, cool down to 500°C, take it out and cool it with anhydrous methanol to prepare the catalyst.

[0035] 50g soybean oil (density is 0.92g / cm3), 1g above-mentioned catalyzer and 21.5ml methanol (density is 0.792g / cm3) mixed solution is put into 250ml triangular grinding mouth flask, is placed on the constant temperature magnetic stirrer and is stirred and heated to 67 -68°C, after 2 hours of reaction, stop stirring and heating. Move the reaction solution to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com