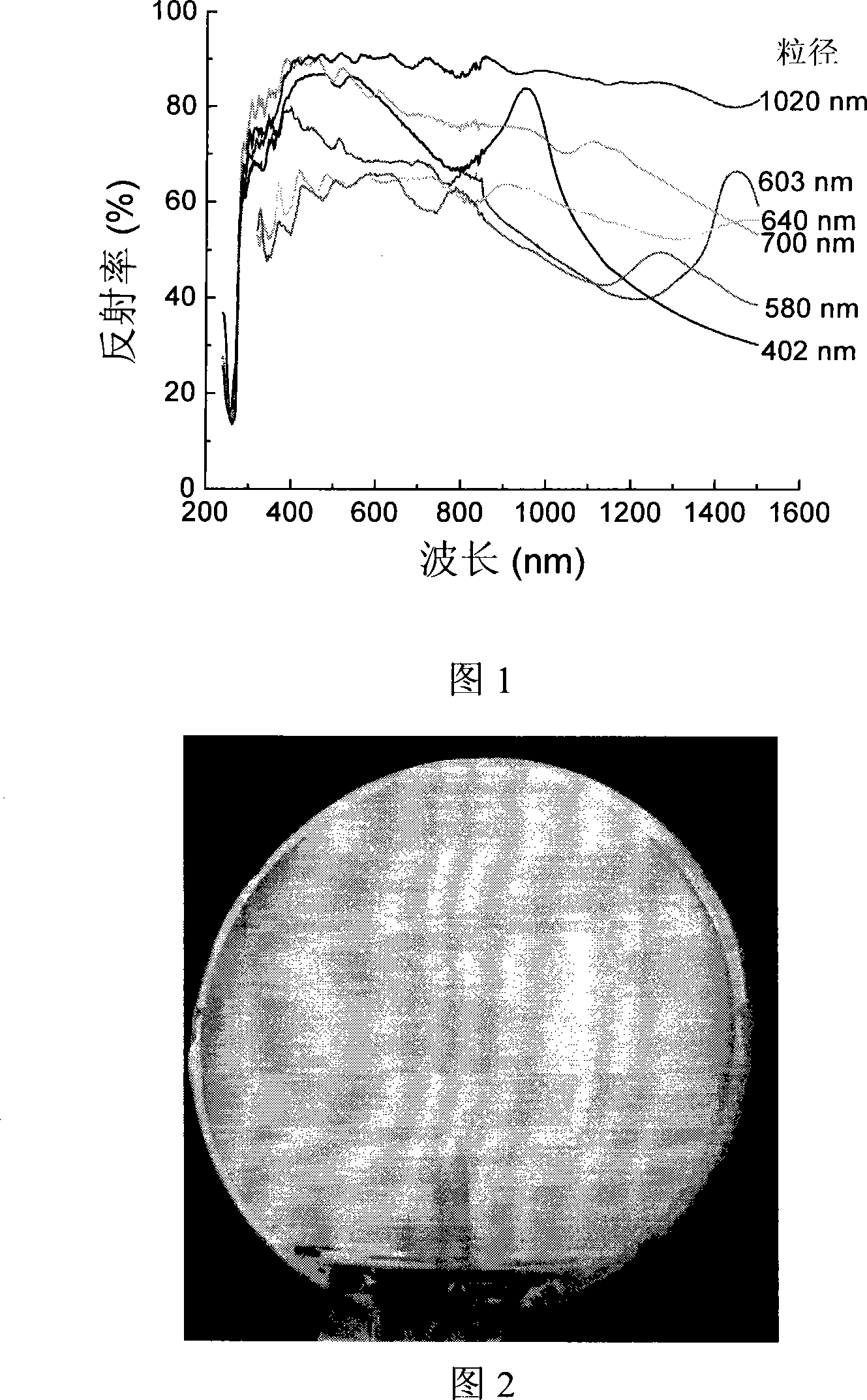

Preparation method of total visible light condenser containing curve surface photon crystal film structure

A photonic crystal and visible light technology, applied in the field of preparation of all-visible light concentrators, can solve the problems of complicated battery process and insignificant enhancement effect, and achieve the effects of improved photoelectric conversion efficiency, strong adhesion and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

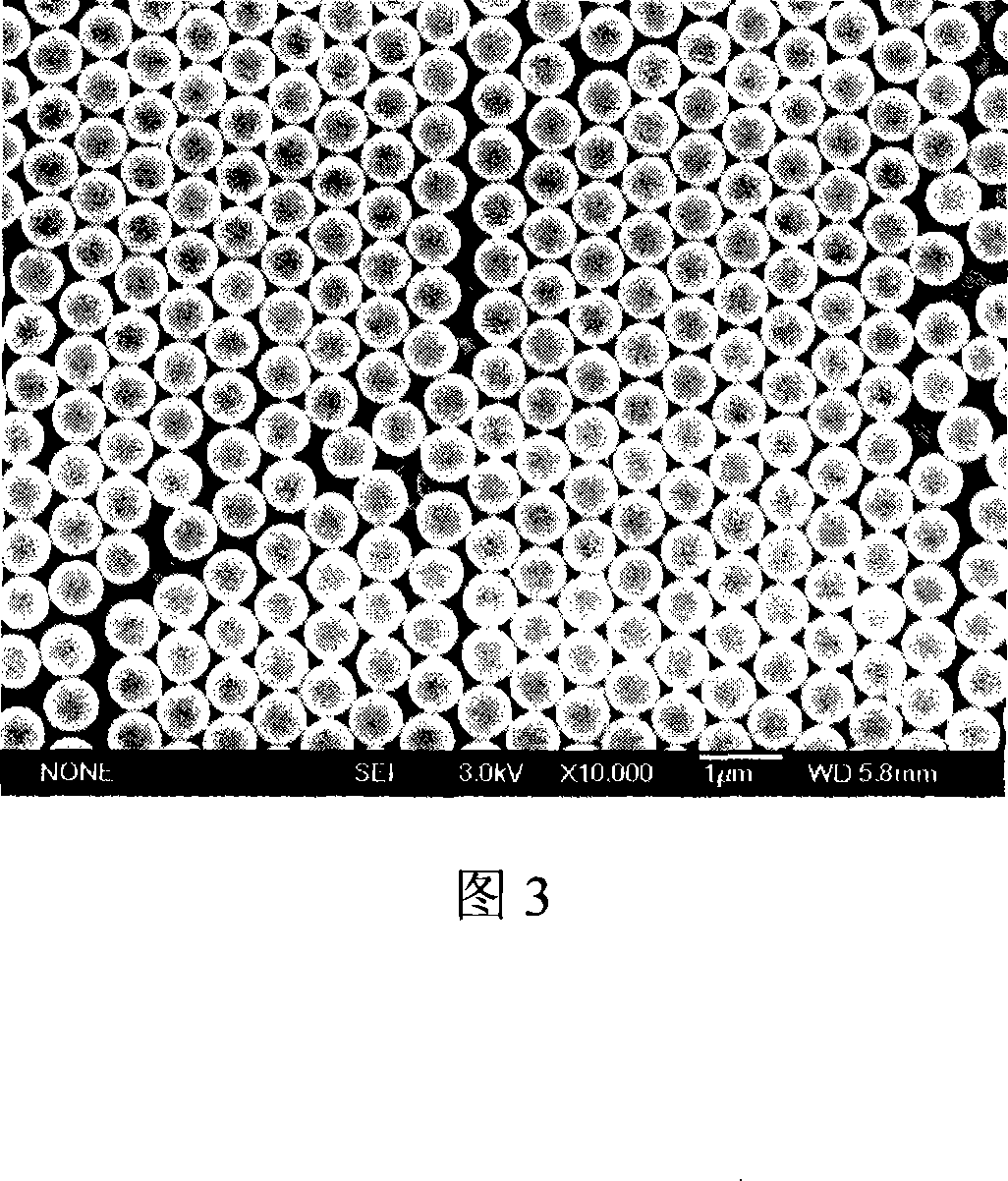

Embodiment 1

[0034] 1. Concave glass substrate treatment: After cleaning the concave glass substrate with detergent, rinse it with tap water, then soak it in lye (such as sodium hydroxide, pH 10-14) for 6 hours, take it out and rinse it with tap water After cleaning, soak in dilute hydrochloric acid solution (pH<5) for more than 10 minutes, rinse with secondary water and dry for later use.

[0035] 2. Prepare the emulsion containing monodisperse polymer latex particles: as previously mentioned, monomer mixture vinyl acetate (0.5 gram), butyl methacrylate (0.5 gram), methyl styrene (19 gram), and Acrylic acid (0.3 gram), pH buffering agent sodium bicarbonate (0.1 gram) and ammonium bicarbonate (0.1 gram) and sodium chloride (0.2g) are dispersed in water (95mL), the mixed system obtained is at 300rpm / min. Mix under stirring and heat to 70°C. Add 15 milliliters of initiator (obtained by dissolving 0.2 gram of ammonium persulfate and 0.1 gram of sodium persulfate in 25 milliliters of water) a...

Embodiment 2

[0040] 1. Concave glass substrate treatment: the same as the treatment method in step 1 in embodiment 1.

[0041] 2. Preparation of an emulsion containing monodisperse polymer latex particles: refer to the technology provided by the application number: 200510011219.2 to prepare an emulsion containing monodisperse polymer latex particles for assembling the membrane. The monomer mixture methyl methacrylate (1 g), styrene (19 g), and methacrylic acid (1 g), pH buffer ammonium bicarbonate (0.2 g) and sodium chloride (0.2 g) were dispersed in In water (95 mL), the obtained mixed system was stirred and mixed at 350 rpm / min, and heated to 70°C. Add 15 milliliters of ammonium persulfate (0.2 gram is dissolved in 25 milliliters of water) aqueous solution and start to react, react and add 5 milliliters of ammonium persulfate aqueous solution again after 2 hours, all the other ammonium persulfate aqueous solutions add after continuing reaction 2 hours, After the reaction continued for 2...

Embodiment 3

[0045] 1. Concave plexiglass substrate processing: with the processing method of step 1 among the embodiment 1.

[0046] 2. Preparation of an emulsion containing monodisperse polymer latex particles: refer to the technology provided by the application number: 200510011219.2 to prepare an emulsion containing monodisperse polymer latex particles for assembling the membrane. A monomer mixture of methyl methacrylate (1 g) and styrene (19 g) was dispersed in water (95 mL), and the resulting mixed system was stirred and mixed at 350 rpm / min, and heated to 70°C. Add 15 milliliters of ammonium persulfate (0.2 gram is dissolved in 25 milliliters of water) aqueous solution and start to react, react and add 5 milliliters of ammonium persulfate aqueous solution again after 2 hours, all the other ammonium persulfate aqueous solutions add after continuing reaction 2 hours, After the reaction continued for 2 hours, the temperature was raised to 80° C. and the reaction was completed for anoth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com