Making method for organic thin film transistor

A manufacturing method and organic thin film technology, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve problems such as poor stability, difficult to reach, difficult to dissolve, etc., and achieve the effect of device performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

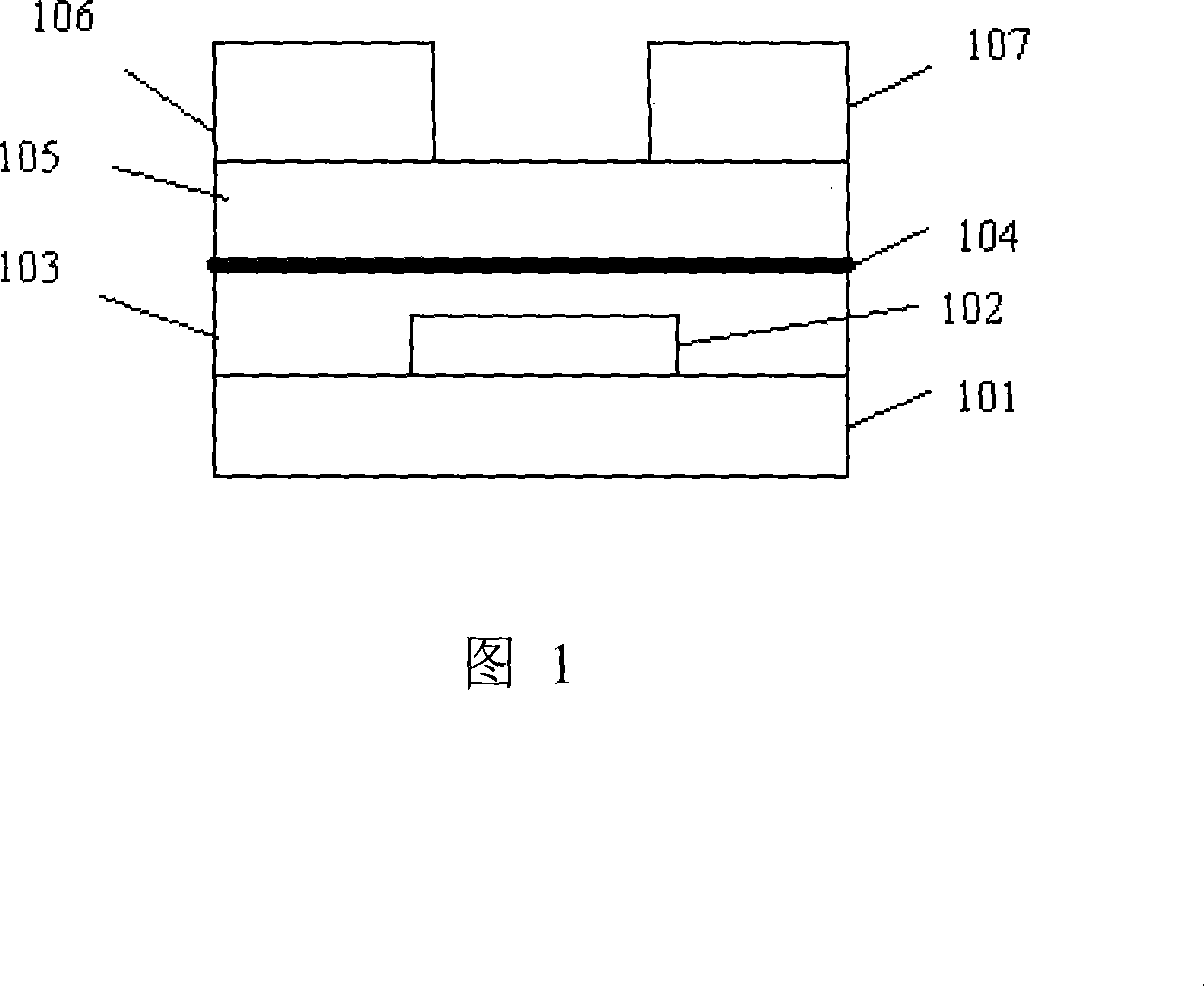

[0027] Step 1, cleaning the ITO glass sheet corroded with hydrochloric acid, the glass sheet is used as the substrate 101, and the ITO is used as the grid 102;

[0028] Step 2, plating silicon dioxide with a thickness of 250 nanometers on the ITO as the gate insulating layer 103;

[0029] The SD400M-MULTISOURCE ORGANICMOLECULAR VAPOR DEPOSITION SYSTEM inorganic coating equipment and NG-3 electron beam evaporation power supply produced by Shenyang Star Vacuum Technology Application Research Institute were used to prepare silicon dioxide films; coating conditions: system vacuum degree 9.8E-4Pa, Foreline vacuum degree 1.OEOPa, growth rate 1 Ȧ / S, deposition time 45 minutes;

[0030] Step 3, transfer the sample treated in step 2 to 2wt% OTS solution (octadecyltrichlorosilane Acros-14740, octadecyltrichlorosilane, molecular formula is C 18 h 37 SiCl 3 , prepared with hexadecane) for 4 hours to form a self-assembled monolayer 104 on the gate insulating layer 103;

[0031] Step 4,...

Embodiment 2

[0038] The other steps are the same as in Example 1, except that the method of forming the self-assembled monolayer 104 on the gate insulating layer 103 is different; using a DEL multifunctional high vacuum system, it is prepared by thermal evaporation, and a few drops of 2wt% The OTS solution is pre-pumped so that the vacuum degree of the chamber is less than 3E-3Pa, and the vapor phase is deposited on the plated silicon dioxide. After 15 minutes of deposition, a self-assembled monolayer 104 is formed on the gate insulating layer 103 .

Embodiment 3

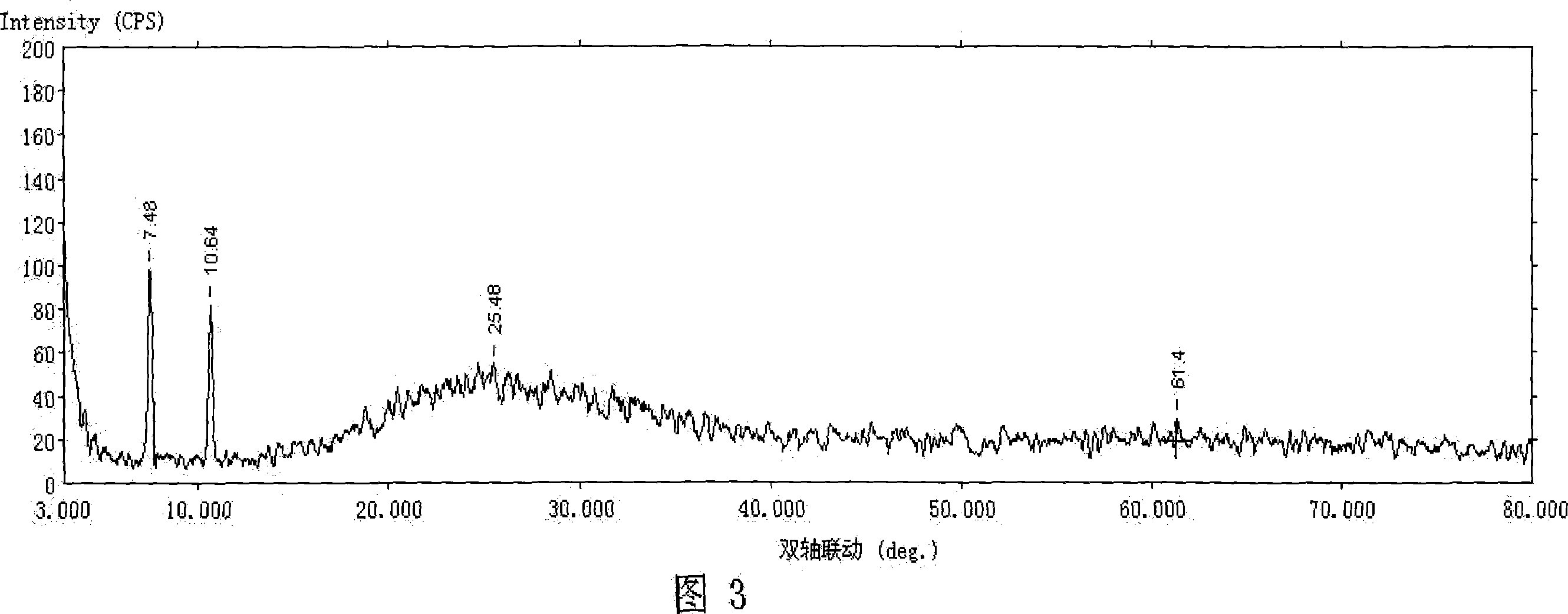

[0040] Other steps are the same as in Embodiment 1, the difference is that the material and formation method of the organic semiconductor layer 105 are different; the coating process of the organic semiconductor layer is carried out, and the pentacene derivative TES thienyl pentacene of the 6,13-substituent is used. Benzene, with the formula

[0041]

[0042] Prepare a 4wt% toluene solution, spin-coat at 2000rpm for 60 seconds and deposit on the sheet, then anneal in air at 90°C for 2 minutes, the precursor of the pentacene derivative is converted into a pentacene film, and the organic semiconductor layer 105 is obtained. .

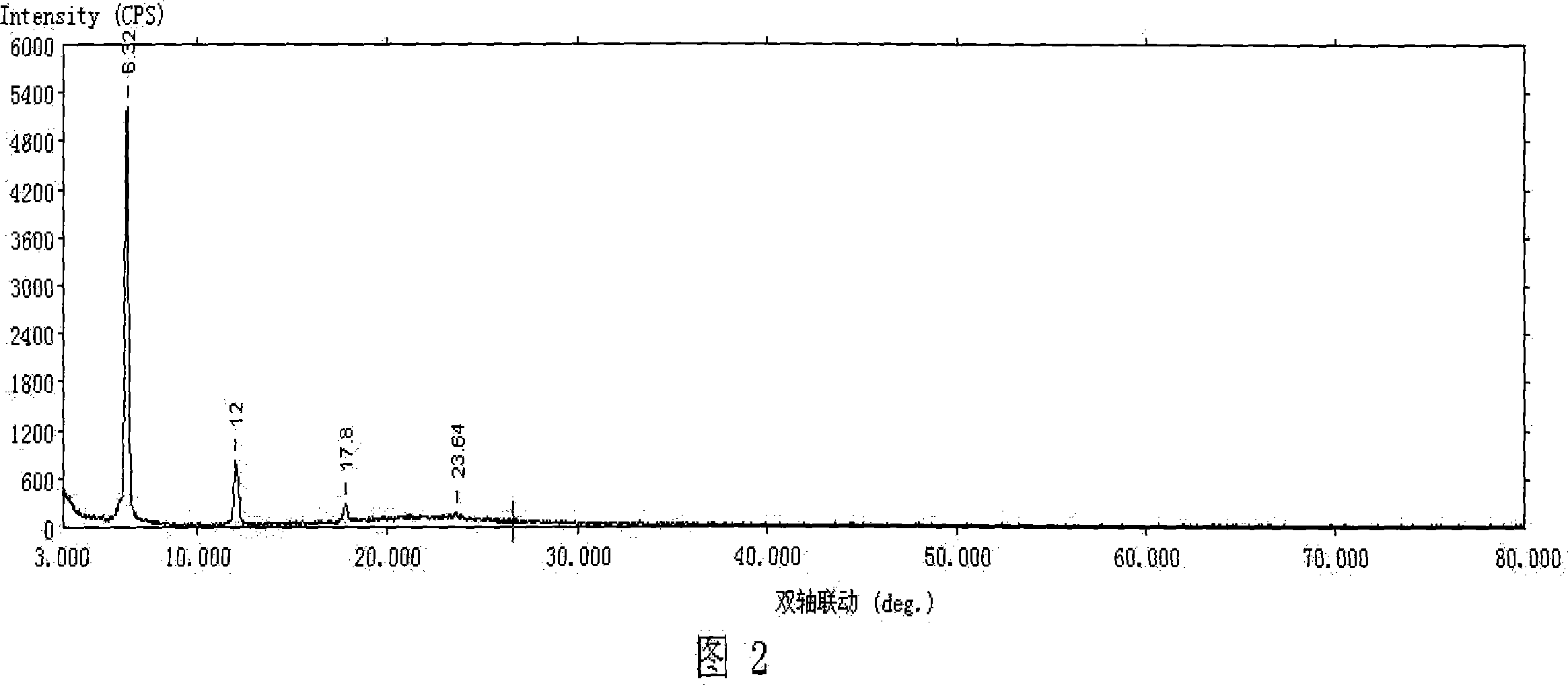

[0043] Using the KEITHLEY 2410 source unit I-V test system to measure the I-V characteristic curve of organic thin film transistor devices, it is obtained that at different gate voltages V GS Next, the source-drain current I DS vs. source-drain voltage V DS The I-V relationship map, and then calculate the mobility in the saturation region according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com