Cracking method for hydrocarbon oil

A hydrocarbon oil and cracking reaction technology, applied in the field of hydrocarbon oil cracking, can solve the problems of low yield of liquid, low yield of dry gas and coke, and high yield of dry gas and coke, so as to reduce the yield of coke and reduce the yield of dry gas. Gas and coke yield, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

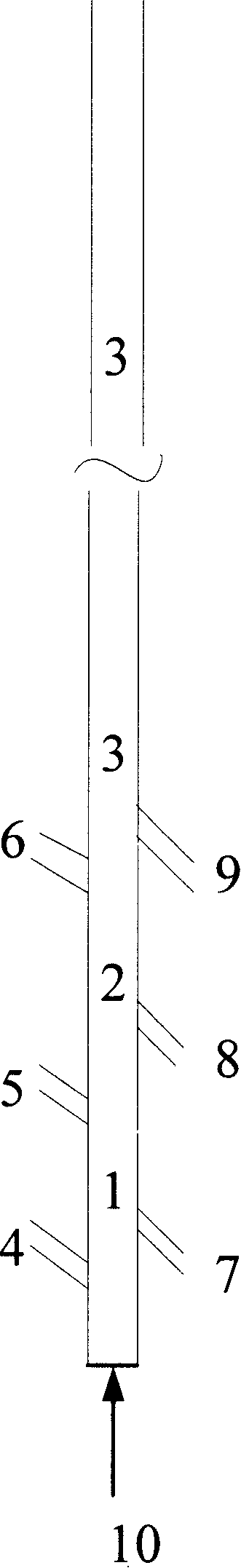

[0046] This embodiment adopts a medium-sized riser reactor, which is a cylindrical structure with a total height of 10 meters and a diameter of 25 centimeters, wherein the height ratio of the lower, middle and upper reaction zones is 0.67:1:7.5. The lowermost part of the riser is the pre-lift section.

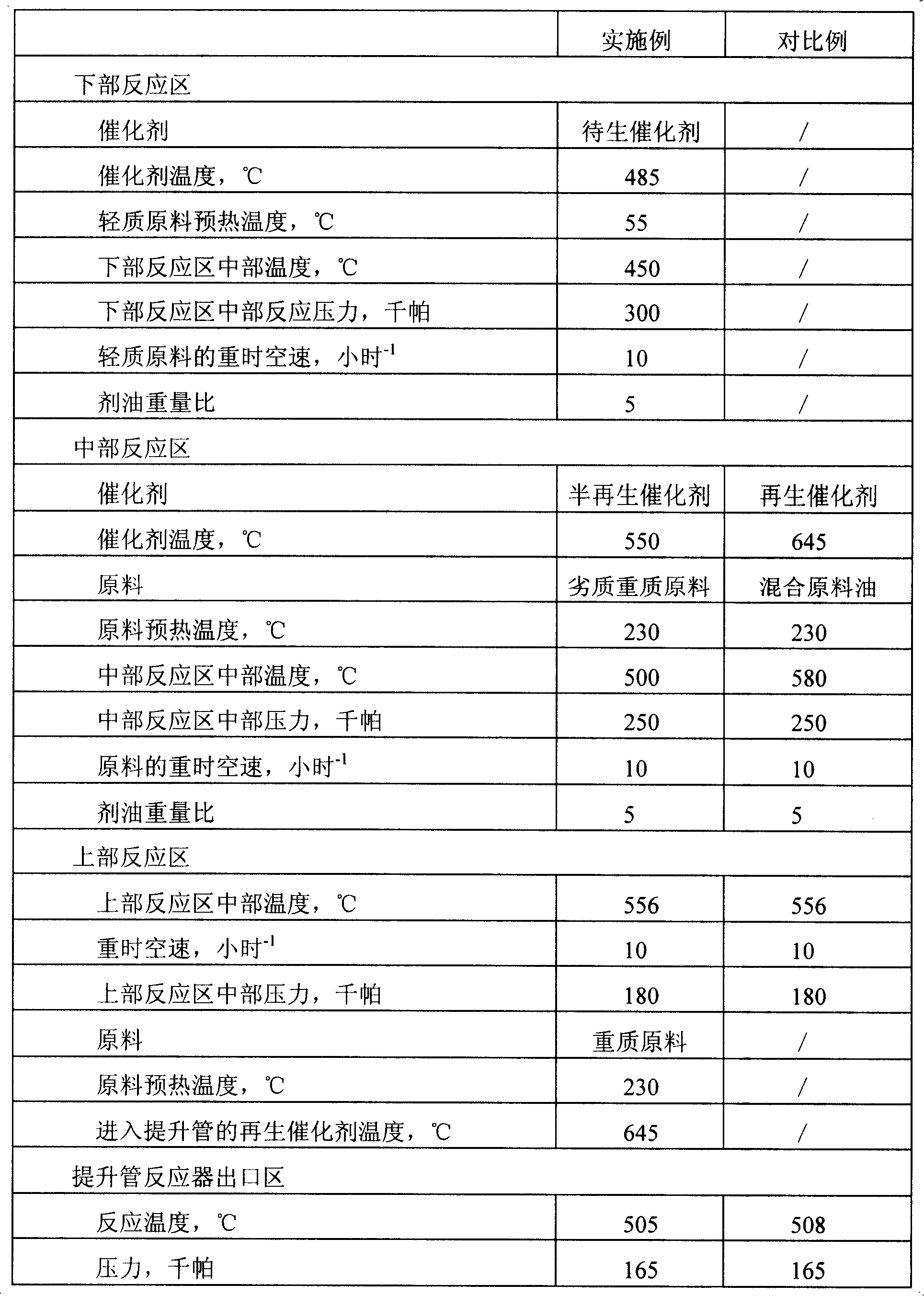

[0047] The raw material oil processed by the device is that the light raw material introduced from the lower reaction zone is catalytic cracking gasoline; the inferior heavy raw material introduced from the middle reaction zone is vacuum residue; the heavy raw material introduced from the upper reaction zone is wax oil ( vacuum gas oil). The feed amount of the catalytic cracking gasoline is 15% by weight of the gas oil, and the feed amount of the vacuum residue is 20% by weight of the gas oil. The properties of various feedstock oils are listed in Table 1. The brand name of the catalyst is LV-23, which is produced by Qilu Catalyst Factory of China Petrochemical Corporation. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com