Bacillus circulans WZ-12 and its application in microorganism resolving treatment of dichloromethane

A technology of Bacillus circulans, methylene chloride, applied in the directions of microorganism-based methods, methods of using microorganisms, microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

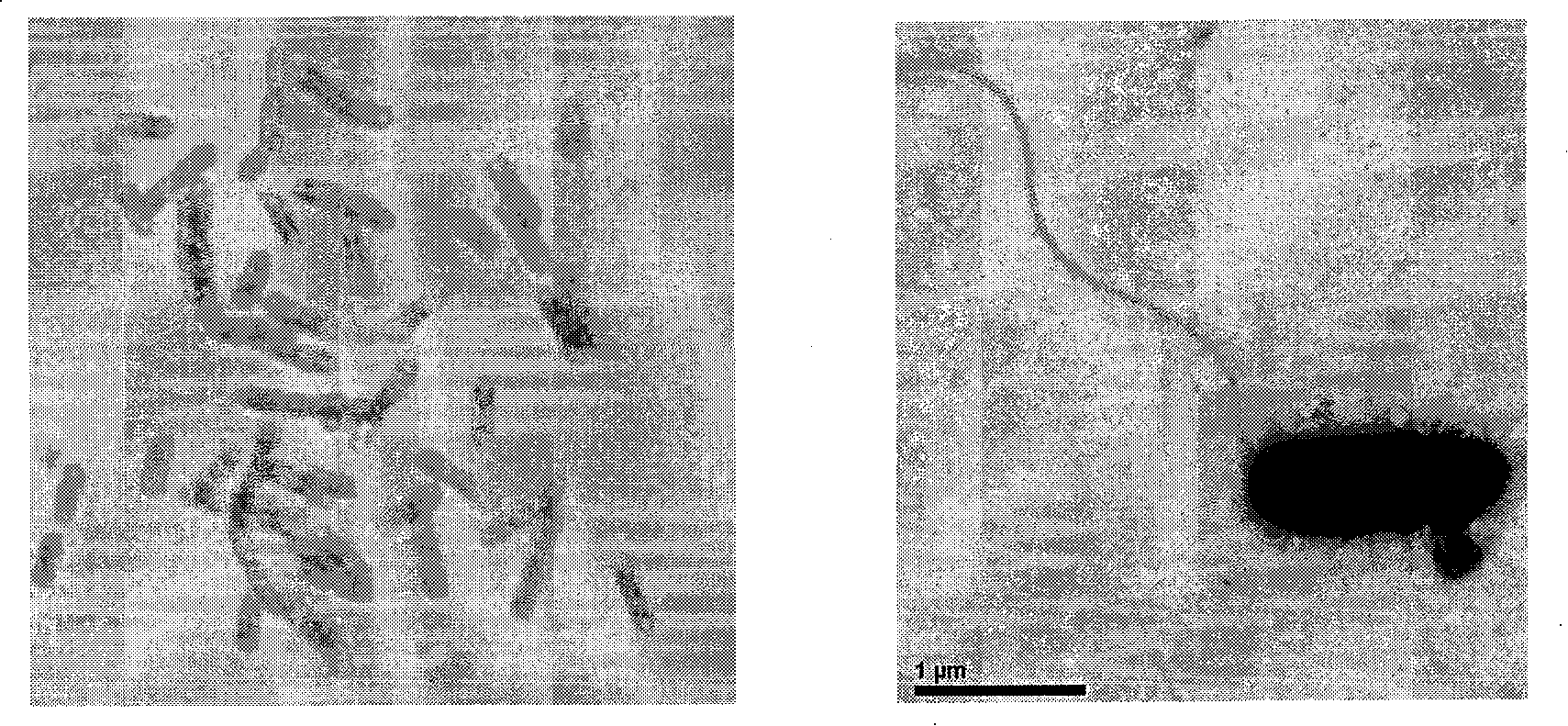

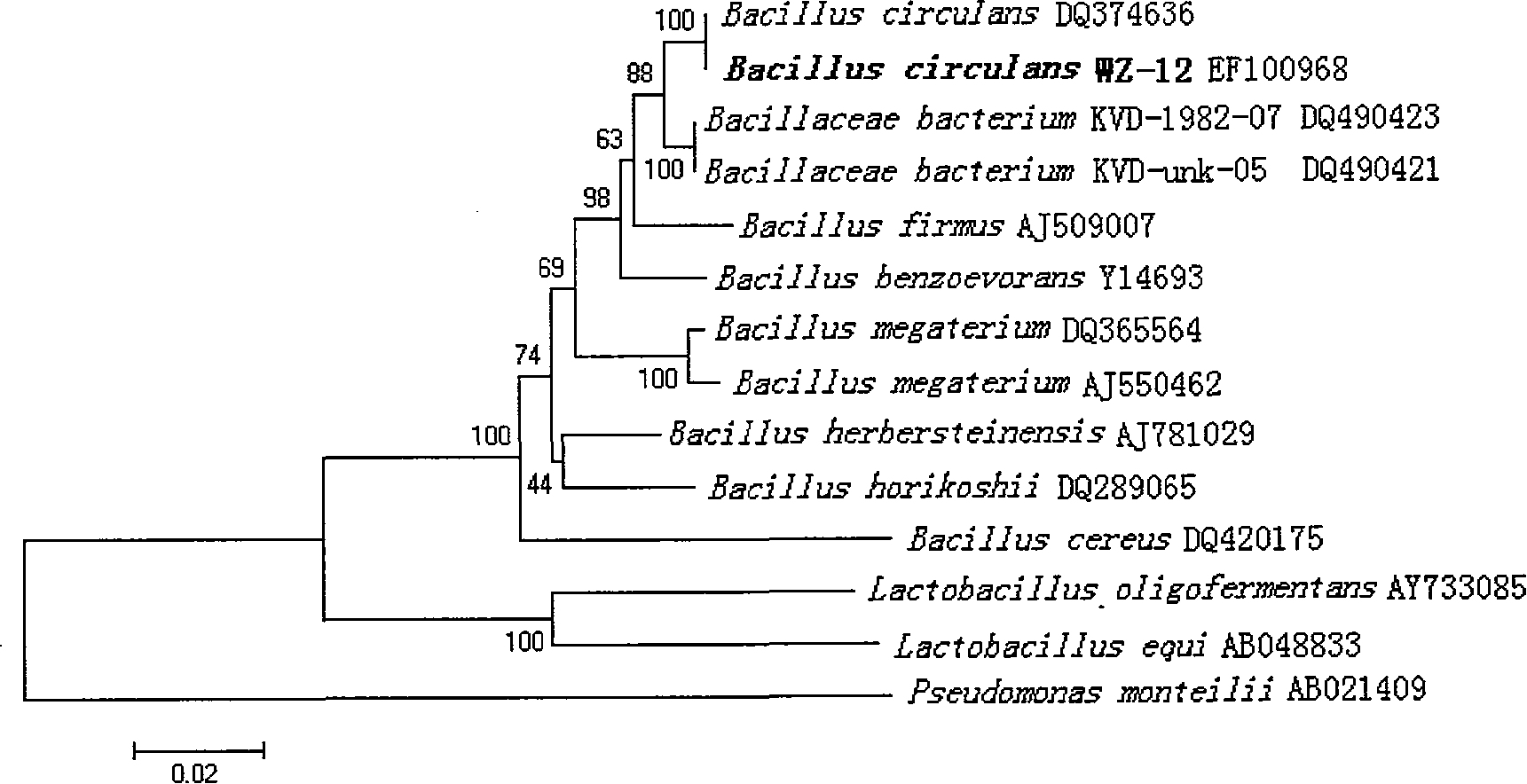

Embodiment 1

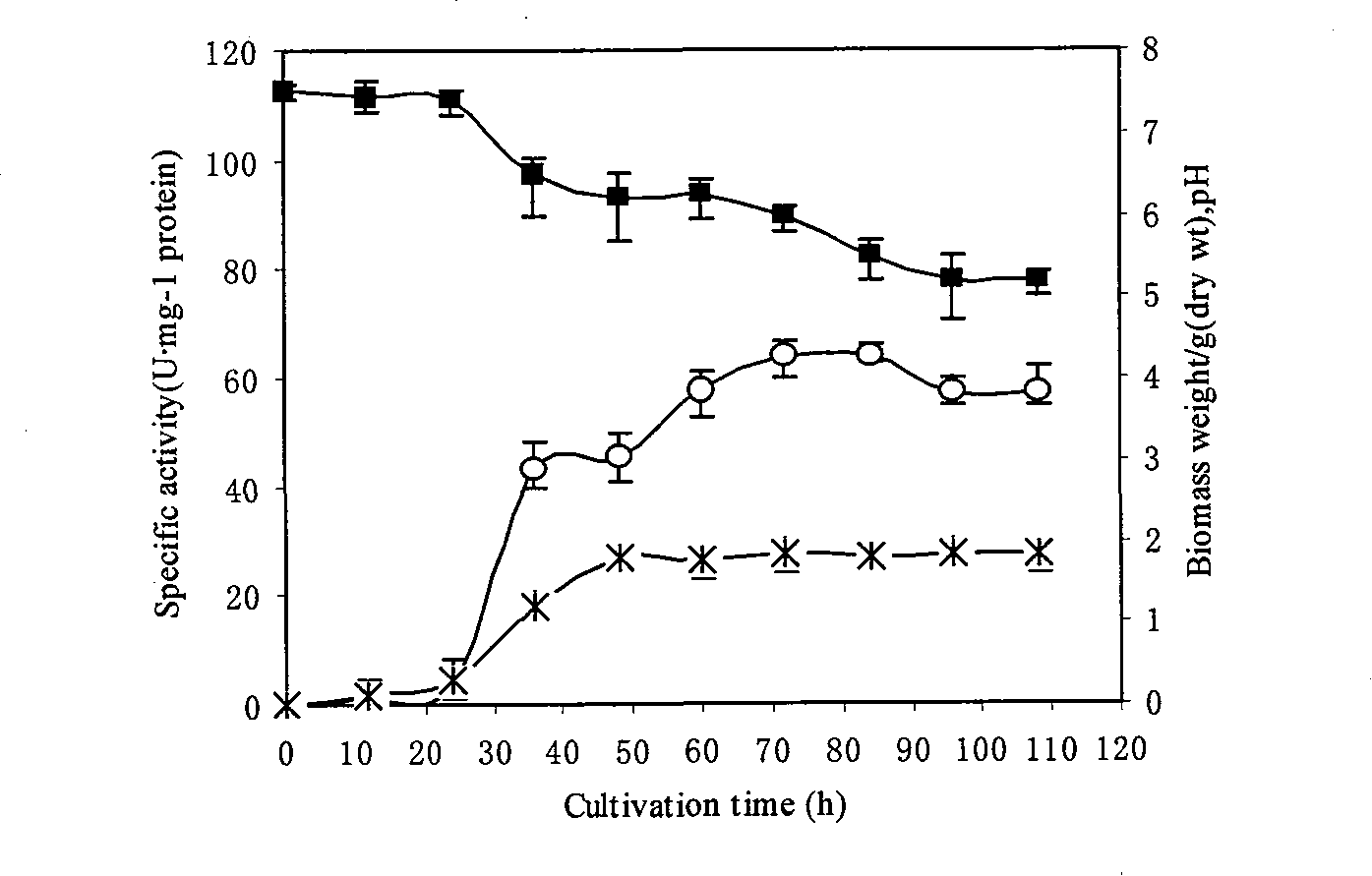

[0075] Example 1: Preparation, separation and purification of dichloromethane dehalogenase from strain WZ-12

[0076] (1) Enzyme-producing culture of the strains: using carbon-free Cha's liquid medium, culturing in seed medium to obtain bacterial suspension, 10ml bacterial suspension (1×10 6 ) Inoculate into a 250ml Erlenmeyer flask containing 100ml of enzyme-producing medium, cover the bottle tightly with a rubber stopper, shake culture at 30°C, CH 2 Cl 2 The final concentration is 32mmol / L, added in 4 times, 8mmol / L each time, pH 7.5, 48h to terminate the culture, to obtain the enzyme-producing culture.

[0077] The final concentration of each component of the seed medium is: NaNO 3 , 2g; K 2 HPO 4 , 1g; KCl, 0.5g; MgSO 4 ·7H 2 O, 0.5g; Fe SO 4 , 0.01g; H 2 O, 1000ml; pH7.0~7.2. Sterilize at 121°C for 20 minutes. Gaseous carbon source CH 2 Cl 2 The final concentration is 32 mM, and it is added in 4 times during culture.

[0078] The final concentration of each component of the e...

Embodiment 2

[0085] Example 2: Application of strain WZ-12 in the treatment of methylene chloride by biological filtration

[0086] (1) Strain culture: use carbon-free Chase solid medium such as Picture 9 Method of cultivation, first spread the strain on the surface of the solid medium, then add a large piece of sterile cotton on the lid of the dish, drop an appropriate amount of dichloromethane into the cotton, cultivate at 30°C, and add dichloromethane regularly. Add sterile normal saline to the cotton on the control plate. After culturing for 2 to 3 days, the obtained single colony is transferred to the inclined surface of the large test tube, and cotton with dichloromethane is placed on the opposite side of the inclined surface of the test tube wall to obtain the inclined surface bacteria. Kind.

[0087] (2) Strain expansion culture: the slant strain is cultivated in the seed medium to obtain a bacterial suspension, 50ml bacterial suspension (cell concentration 1×10 6 Pieces / mL) inoculate ...

Embodiment 3

[0089] Example 3: Using industrial microbial breeding methods to improve the efficiency of methylene chloride degradation

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com