Method for preparing ITO nanometer line and gas sensor thereof

A gas sensor and nanowire technology, applied in the direction of material resistance, etc., to achieve high sensitivity, good gas sensitivity characteristics, and reduce the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

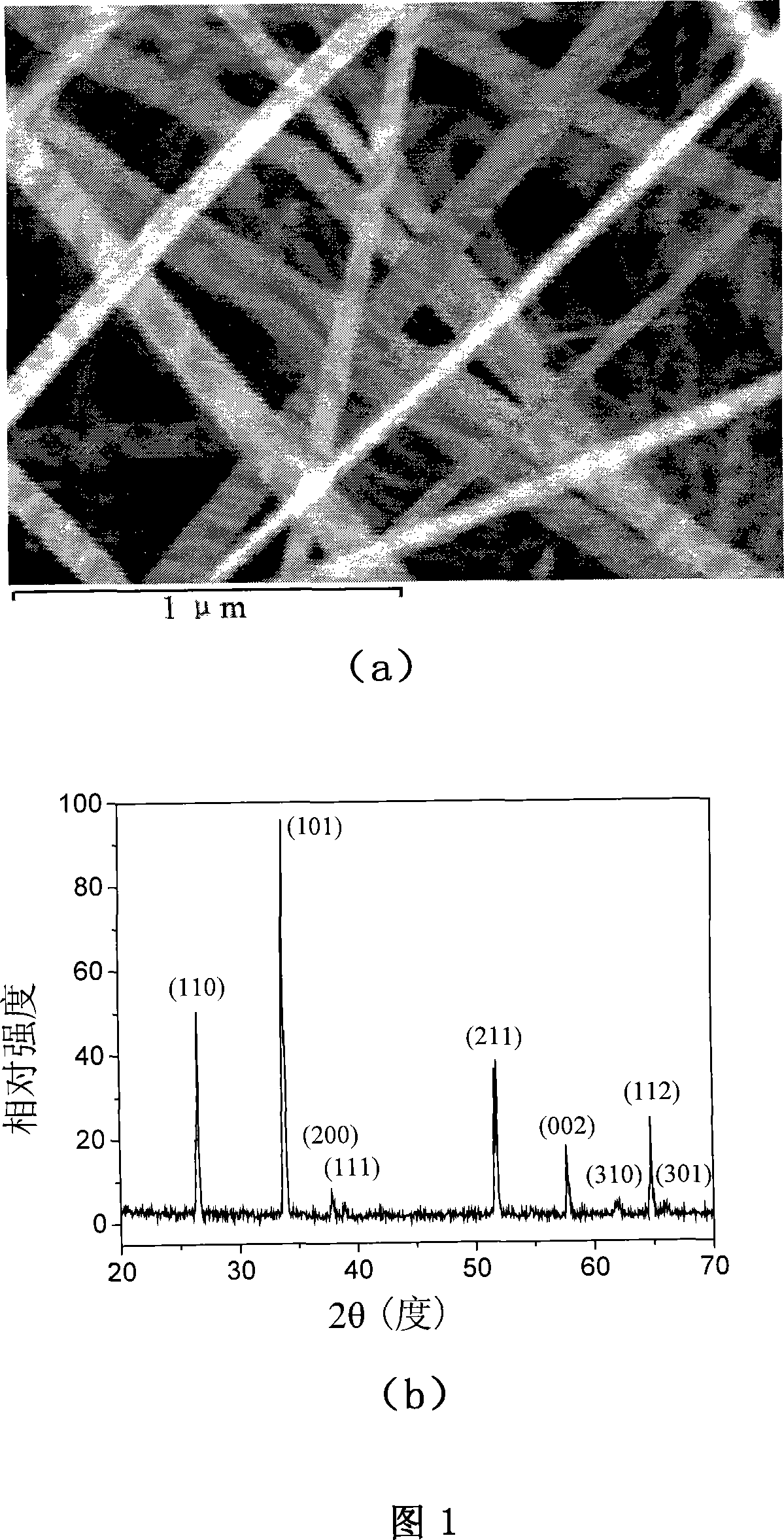

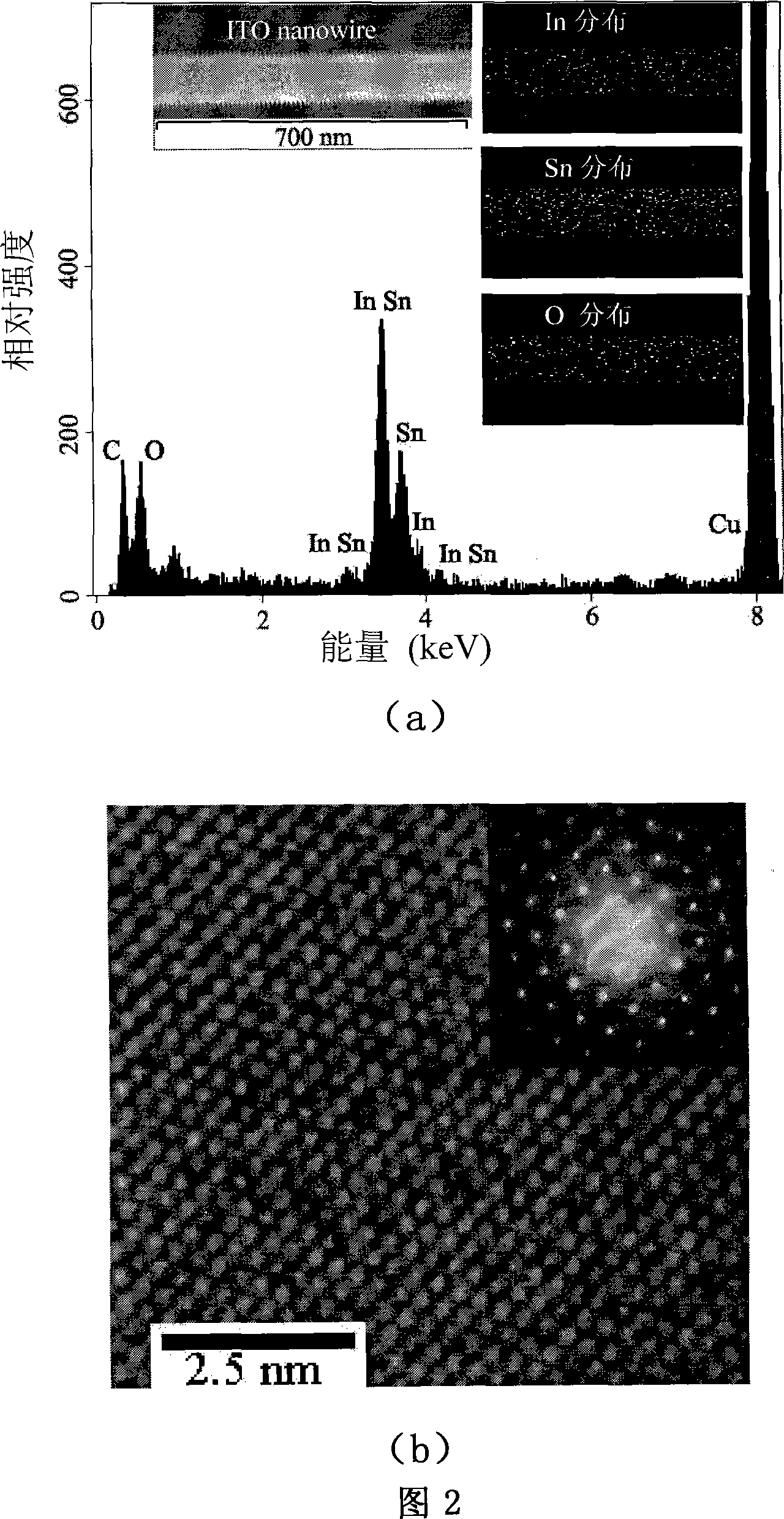

[0042] Embodiment 1: ITO nanowire preparation method:

[0043] (1) 5 nanometers thick gold film is deposited on the base substrate;

[0044] (2) After the powders of indium oxide, stannous oxide and graphite are fully mixed with a mass ratio of 1: 3.8: 0.8, the mixed powder is put into an alumina boat, and the substrate substrate is placed on the alumina boat;

[0045] (3) Put the alumina boat into the quartz tube, then put the quartz tube into the tube furnace, and then heat the tube furnace to 600°C for 1 minute;

[0046] (4) After the tube furnace is cooled to room temperature, the slightly yellow product-ITO nanowires are generated on the substrate;

[0047] During the above preparation process, the gas pressure in the quartz tube was 250 Pa, and a mixed gas of argon and oxygen was fed at a rate of 10 sccm at the same time, and the volume ratio of oxygen in the mixed gas was 5%.

[0048] The base substrate is an N-type silicon substrate, and the gold film is deposited by...

Embodiment 2

[0049] Embodiment 2: ITO nanowire preparation method:

[0050] (1) spraying a 1 micron thick gold film on the base substrate;

[0051] (2) After the powders of indium oxide, stannous oxide and graphite are fully mixed with a mass ratio of 1: 4.2: 1.2, the mixed powder is placed in an alumina boat, and the substrate substrate is placed on the alumina boat;

[0052] (3) Put the alumina boat into the quartz tube, then put the quartz tube into the tube furnace, then heat the tube furnace to 1200°C for 10 hours;

[0053] (4) After the tube furnace is cooled to room temperature, the slightly yellow product-ITO nanowires are generated on the substrate;

[0054] During the above preparation process, the air pressure in the quartz tube is 250-350 Pa, and at the same time, a mixed gas of nitrogen and oxygen is fed at a speed of 30 sccm, and the volume ratio of oxygen in the mixed gas is 20%. The base substrate is a P-type silicon substrate, and the gold film is deposited by sputtering...

Embodiment 3

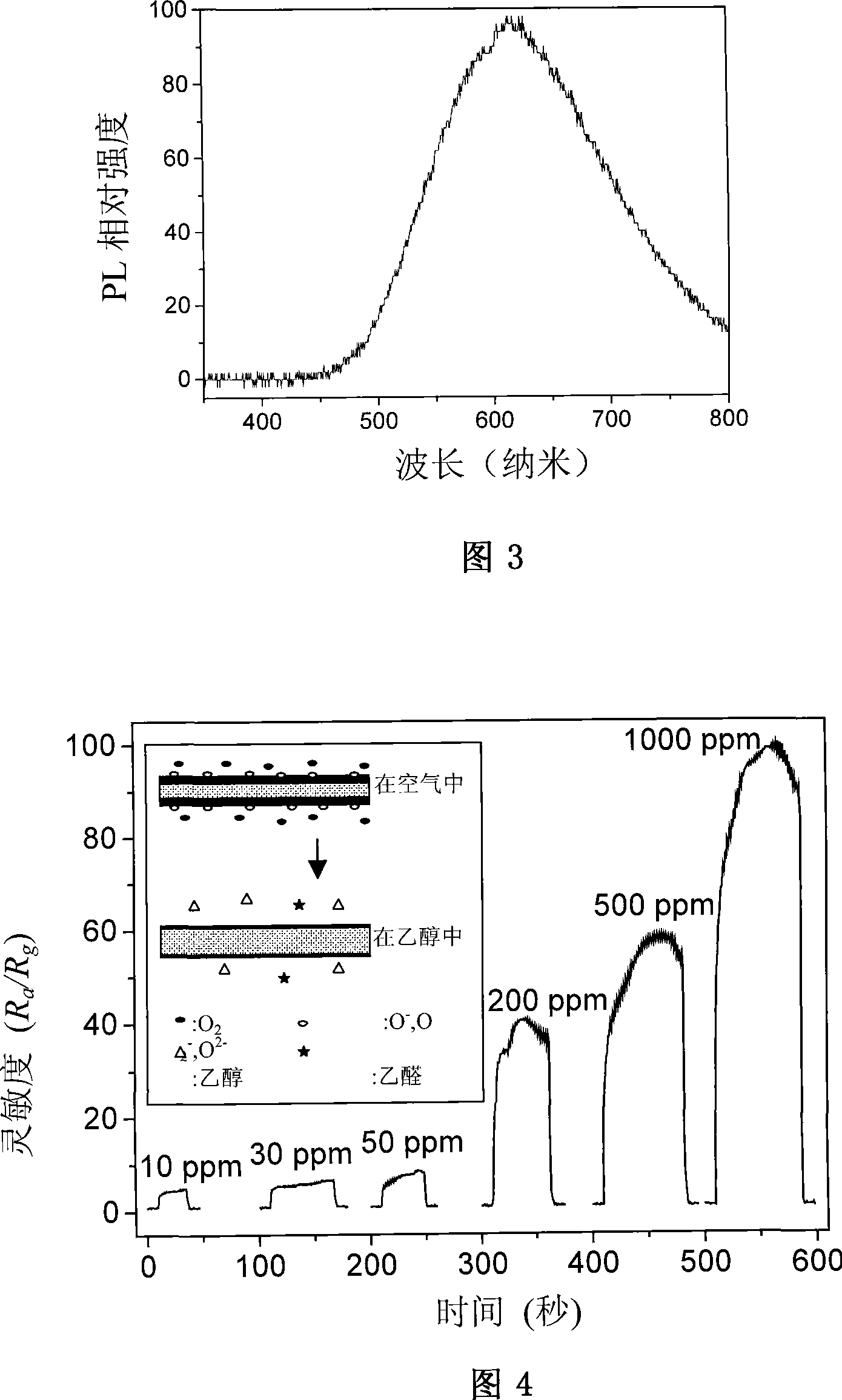

[0055] Embodiment 3: the preparation of ITO nanowire gas sensor:

[0056] (1) ITO nanowires are uniformly dispersed in an ethanol solution to make a slurry;

[0057] (2) coating the slurry on a ceramic tube with two gold electrodes and covering the electrodes;

[0058] (3) drying or sintering, that is, heating to 50°C for 10 hours;

[0059] (4) Lead connection. The resulting product is aged for 24 hours.

[0060] The substrates of the two electrodes are realized by photolithography on the ceramic sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com