Chemical preparation method of silver dendritic structure period arrangement

A technology of periodic arrangement and periodic structure, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of agglomeration, difficult application of dendritic and fractal nanostructured materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

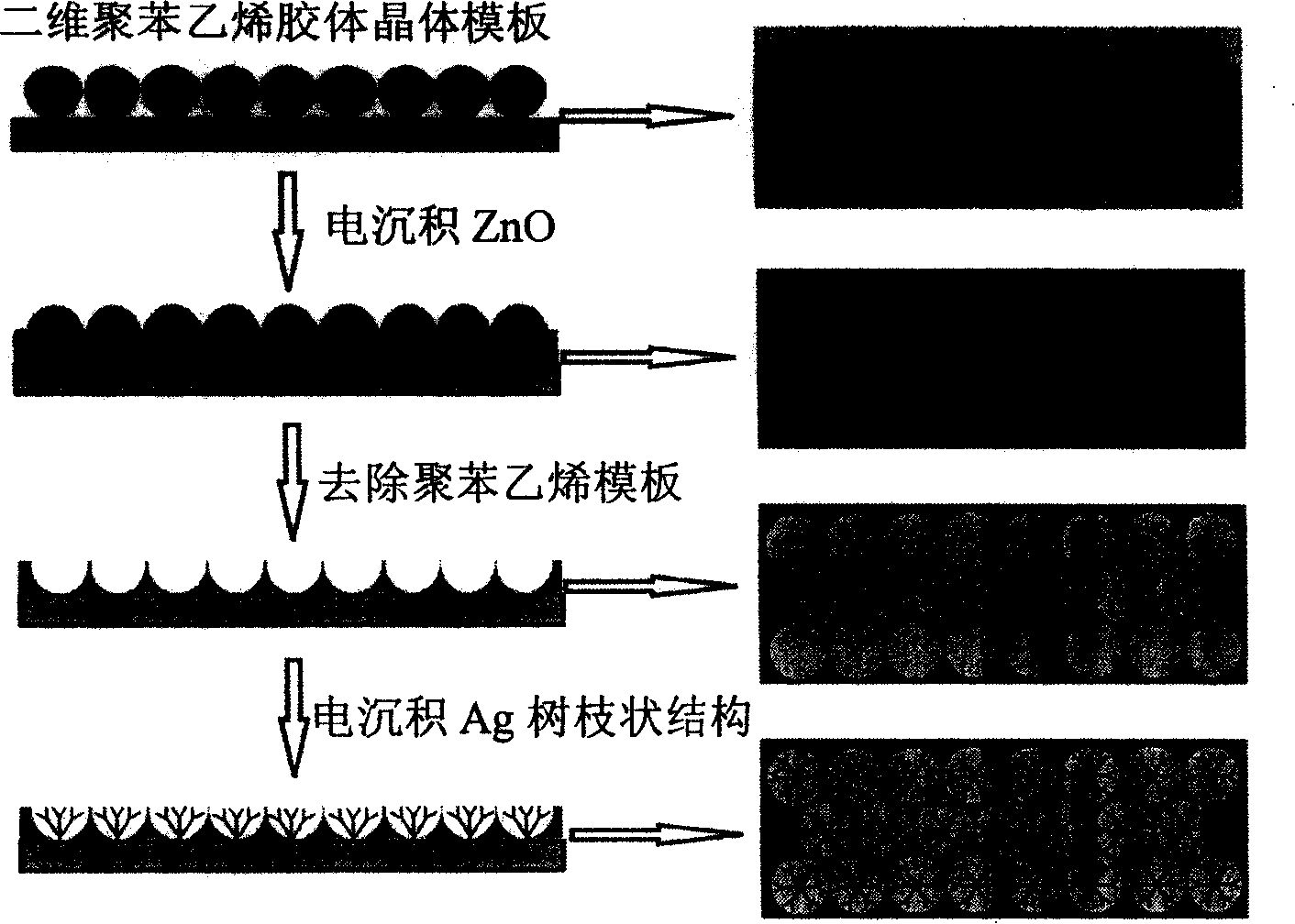

Method used

Image

Examples

preparation example Construction

[0011] 1. Preparation of polystyrene microspheres: Using emulsion polymerization, add styrene monomer and emulsifier sodium dodecyl sulfate (SDS) into ultrapure water, and mix well by ultrasonic and electromagnetic stirring to form O / W emulsion; above-mentioned emulsion is added in the three-necked bottle that is connected with stirrer, condensing pipe and nitrogen gas introduction interface, stirs under the water bath condition of 60~80 ℃, and add initiator potassium persulfate dropwise after logical nitrogen 15~40 minutes ( KPS) aqueous solution, after 10~24 hours of constant temperature reaction under the condition of logical nitrogen, cool down naturally. Polystyrene microspheres with a particle diameter of 500 nm to 2.5 μm are obtained.

[0012] 2. Vertical pulling method to prepare polystyrene single-layer colloidal crystal film: first, the conductive glass coated with indium tin oxide is cut into long 3cm, wide 1cm sheet (thickness 1mm), then in dilute ammonia water: H...

Embodiment 1

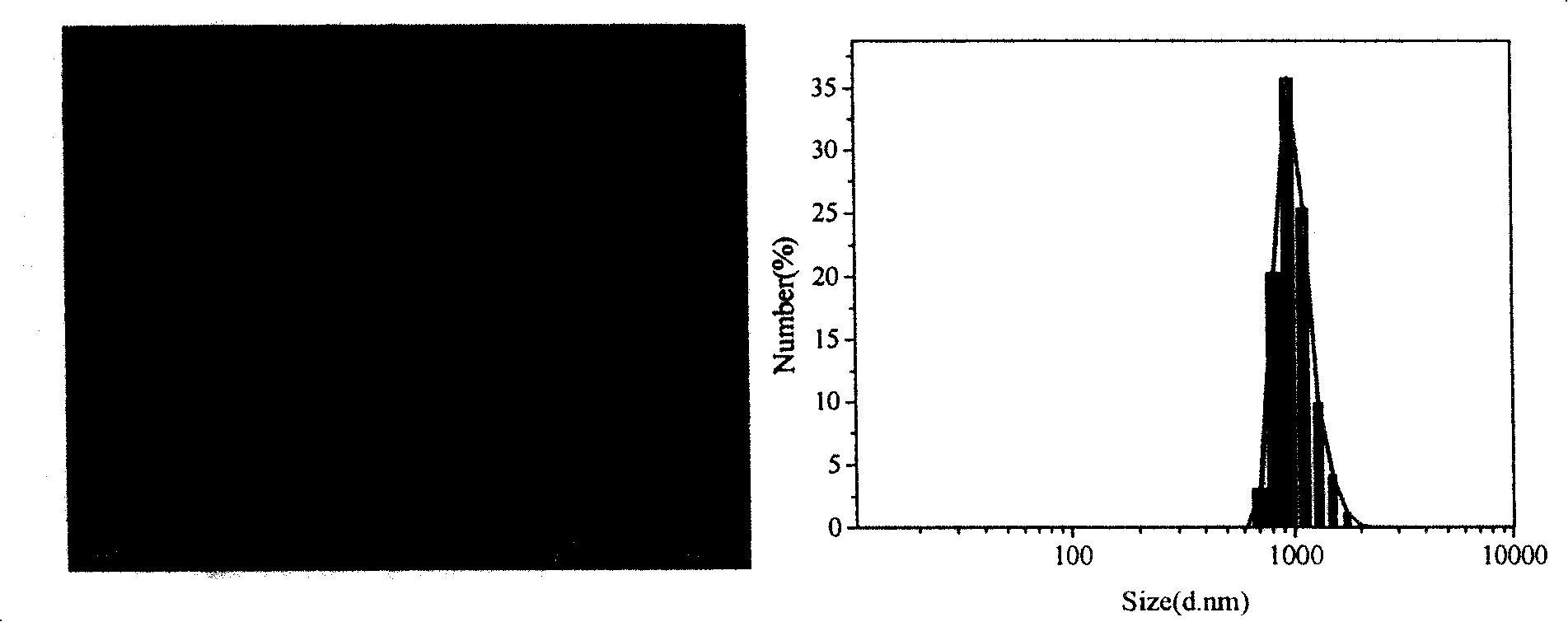

[0016] Embodiment one: in the process of preparing polystyrene microspheres, adopt emulsion polymerization method, 3.25g styrene monomer and 0.02g emulsifier sodium dodecyl sulfate (SDS) are added into 32.3g ultrapure water, Thoroughly mix uniformly by ultrasonic and electromagnetic stirring to form O / W emulsion; put the above emulsion into a three-necked bottle connected with a stirrer, a condenser tube and a nitrogen inlet port, stir in a water bath at 68°C, and pass nitrogen gas for 30 minutes, then gradually Add dropwise an aqueous solution of initiator potassium persulfate (KPS) (0.0325gKPS / 5gH 2 (0), then naturally cool down after 12 hours of constant temperature reaction under the condition of nitrogen gas. Obtain the polystyrene microsphere white emulsion of average particle diameter 950nm as attached figure 2 shown.

Embodiment 2

[0017] Example 2: In the process of polystyrene two-dimensional single-layer colloidal crystal template, the polystyrene white emulsion prepared above was repeatedly centrifuged and washed several times by vertical pulling method, and then prepared into a solution with a mass percentage of about 1.0% , and poured into a square glass vessel with a side length of 3.0cm. The conductive glass coated with indium tin oxide was sequentially mixed in 25% dilute ammonia water: 30% H 2 o 2 :H 2 O=1:2:5 mixed solution, acetone, ethanol and a large amount of ultrapure water were sonicated for 15 minutes, and then dried with nitrogen. Insert the cleaned conductive glass vertically into the glass vessel containing the polystyrene emulsion and put it in a drying oven at 50°C, place it in a closed environment for 72 hours and then take it out. The conductive glass assembled with polystyrene microspheres was placed in a vacuum oven with a vacuum degree of 0.08 MPa and cured at 65°C for 2 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com