Rapidly effectual aluminum magnesium carbonate preparation and technique of preparing the same

A technology of aluminum magnesium carbonate and preparation, which is applied in the directions of non-active ingredients medical preparations, pill delivery, aluminum/calcium/magnesium active ingredients, etc., can solve the problems of reducing production cost, long time, and drug onset after 30 minutes, etc. , to achieve the effect of low manufacturing cost, no toxic side effects and adverse reactions, and easy to collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

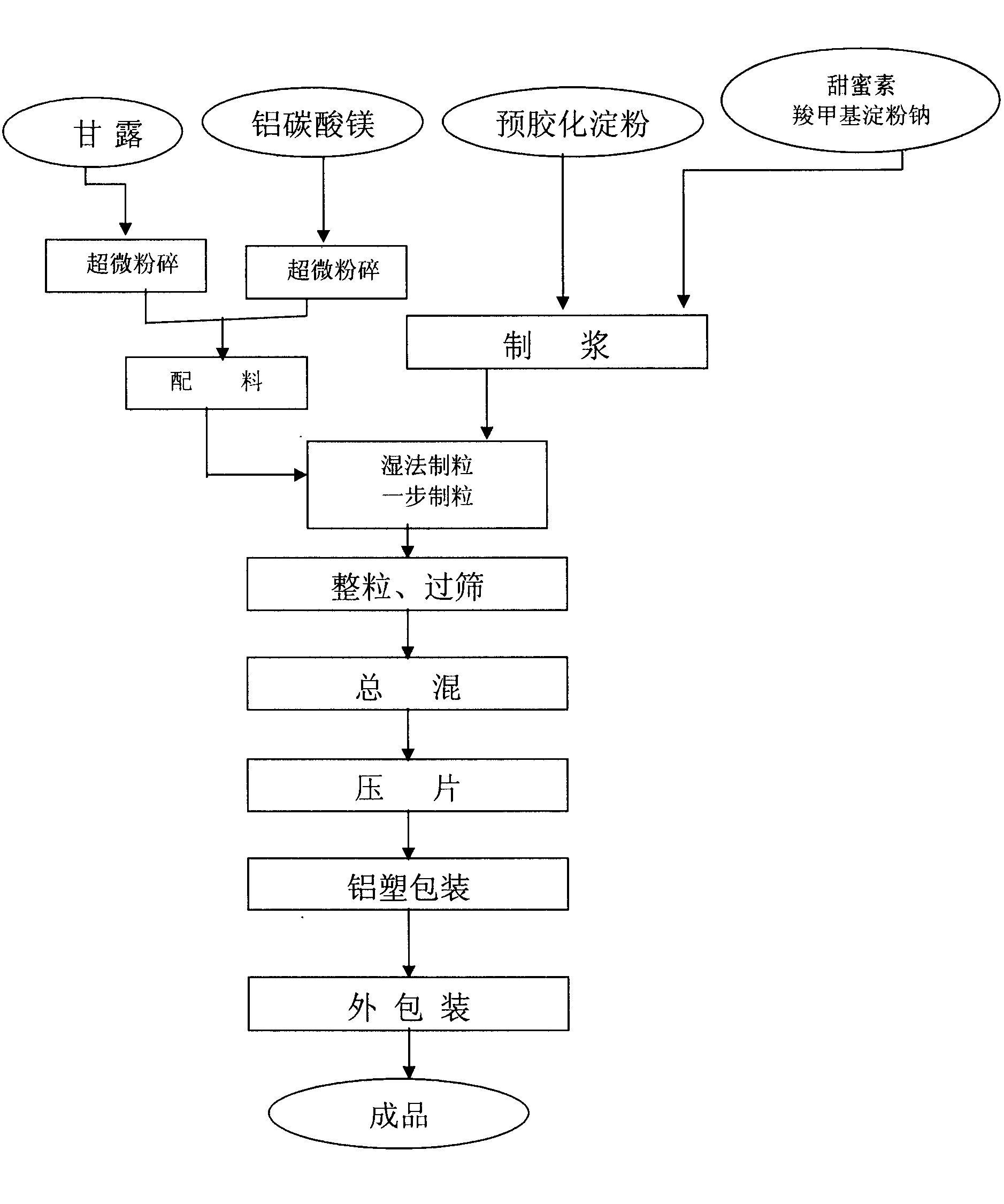

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 prepares 1000 aluminum magnesium carbonate sheets

[0020] a. prepare the superfine powder of aluminum magnesium carbonate and mannitol

[0021] Aluminum magnesium carbonate and mannitol are made into ultra-fine powder with a particle size of 0.5 μm, ready for use, process conditions: air consumption 40M 3 / min, working pressure 0.75Mpa, feed particle size 60 mesh

[0022] b. wet granulation

[0023] According to 1000 preparation units, take aluminum magnesium carbonate powder 0.45kg, mannitol 0.18kg and carboxymethyl starch sodium 12g and add in the wet granulator, start the wet granulator and stir at a low speed (1000r / min) for 3 minutes to make it Mix well; dissolve 0.5g of cyclamate in about 0.5Kg of purified water, start the wet granulator to stir at a low speed of 1000r / min and cut at a low speed of 1500r / min for 1 minute, so that the solution of cyclamate is mixed in the wet granulator , then change the low-speed cutting to 3000r / min high-speed cu...

Embodiment 2

[0028] Embodiment 2 prepares 1000 aluminum magnesium carbonate sheets

[0029] a. prepare the superfine powder of aluminum magnesium carbonate and mannitol

[0030] Aluminum magnesium carbonate and mannitol are made into superfine powder with a particle size of 3 μm, ready for use, process conditions: air consumption 40M 3 / min, working pressure 0.8Mpa, feed particle size 100 mesh

[0031] b. wet granulation

[0032] According to 1000 preparation units, take aluminum magnesium carbonate powder 0.5kg, mannitol 0.20kg and carboxymethyl starch sodium 15g and add in the wet granulator, start the wet granulator and stir at a low speed (1000r / min) for 4 minutes to make it Mix evenly; dissolve 0.75g of cyclamate in about 0.5Kg of purified water, start the wet granulator to stir at a low speed of 1000r / min and cut at a low speed of 1500r / min for 1 minute, so that the solution of cyclamate is mixed in the wet granulator Evenly, then change the low-speed cutting to 3000r / min high-spe...

Embodiment 3

[0037] Embodiment 3 prepares 1000 aluminum magnesium carbonate sheets

[0038] a. prepare the superfine powder of aluminum magnesium carbonate and mannitol

[0039] Aluminum magnesium carbonate and mannitol are made into superfine powder with a particle size of 15 μm, ready for use, process conditions: air consumption 40M 3 / min, working pressure 0.85Mpa, feed particle size 300 mesh

[0040] b. wet granulation

[0041] According to 1000 preparation units, take aluminum magnesium carbonate powder 0.55kg, mannitol 0.25kg and carboxymethyl starch sodium 18g and add in the wet granulator, start the wet granulator and stir at a low speed (1000r / min) for 5 minutes to make it Mix evenly; dissolve 1.0g cyclamate in about 0.5Kg purified water, start the wet granulator to stir at a low speed of 1000r / min and cut at a low speed of 1500r / min for 1 minute, so that the solution of cyclamate is mixed in the wet granulator , then change the low-speed cutting to 3000r / min high-speed cutting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com