Method for recycling ion liquid from filature wastewater

An ionic liquid and wastewater technology, applied in general water supply conservation, chemical instruments and methods, heating water/sewage treatment, etc., can solve problems such as difficulty in high-quality concentration brine treatment, high energy consumption by direct distillation, unfavorable energy conservation and emission reduction, etc. Achieve the effect of high recovery rate, low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

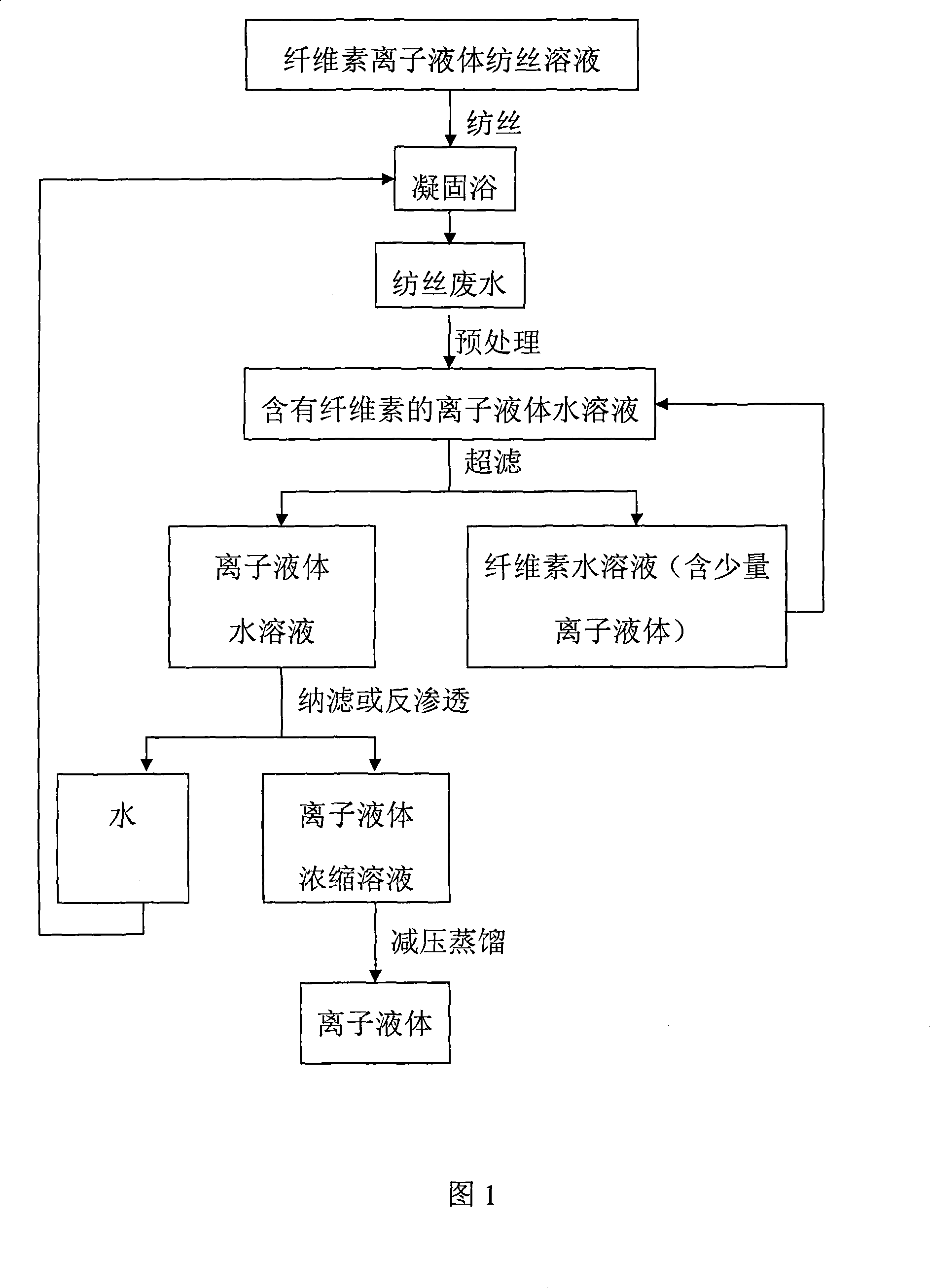

Image

Examples

Embodiment 1

[0027] The method of the present invention is used to treat the spinning wastewater obtained by preparing wood pulp cellulose fibers with ionic liquid 1-allyl-3-methylimidazolium chloride salt as a solvent, and the mass concentration of the ionic liquid is 0.01%:

[0028] 1. Pretreatment. The spinning waste water containing wood pulp cellulose fiber is subjected to the pretreatment process of sedimentation, rough filtration and fine filtration in order to filter out the mechanical impurities in it to obtain the pretreatment liquid.

[0029] 2. Ultrafiltration process treatment. Using an ultrafiltration membrane with a molecular weight cut-off of 6000, the pretreatment liquid obtained in the first step of ultrafiltration separation treatment at 0.01MPa is obtained to obtain an aqueous ionic liquid solution with a mass concentration of no wood pulp cellulose and still about 0.01%; the separated The wood pulp cellulose aqueous solution is directly returned to the pretreatment li...

Embodiment 2

[0033] Using the method of the present invention to treat the spinning waste water obtained by preparing polyacrylonitrile fibers with ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate as a solvent, the mass concentration of the ionic liquid is 0.5%:

[0034] 1. With embodiment 1;

[0035] 2. Ultrafiltration process treatment. Using an ultrafiltration membrane with a molecular weight cut-off of 10,000, the pretreatment solution obtained in the first step of ultrafiltration separation treatment at 0.1MPa is obtained to obtain an aqueous ionic liquid solution that does not contain polyacrylonitrile and still has a mass concentration of about 0.5%; the separated The polyacrylonitrile aqueous solution is directly returned to the pretreatment liquid.

[0036] 3. Nanofiltration concentration treatment. The ionic liquid aqueous solution obtained in the second step is used as the raw water concentrated by nanofiltration to carry out nanofiltration concentration treatment, t...

Embodiment 3

[0039] Treat the spinning wastewater obtained by preparing cellulose (microcrystalline cellulose) fibers with the ionic liquid 1-butyl-3-methylimidazolium chloride salt as a solvent with the method of the present invention, and the mass concentration of its ionic liquid is 3%:

[0040] 1. With embodiment 1;

[0041] 2. Ultrafiltration process treatment. Using an ultrafiltration membrane with a molecular weight cut-off of 6000, the pretreatment solution obtained in the first step of ultrafiltration separation treatment at 0.01MPa is obtained to obtain an aqueous ionic liquid solution that does not contain microcrystalline cellulose and still has a mass concentration of about 1%. The cellulose aqueous solution is directly returned to the pretreatment liquid.

[0042] 3. Nanofiltration concentration treatment. The ionic liquid aqueous solution obtained in the second step is used as the raw water concentrated by nanofiltration to carry out nanofiltration concentration treatment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com