Seed culture medium produced with lincomycin ferment optimized with response surface method

A culture medium, the technology of Streptomyces lincous, applied in the field of microbial fermentation, can solve the problems of prolonging the cultivation time, seed aging, long cultivation period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Embodiment 1 two-level factorial design (2Level Factorial Design)

[0080] In this example, significant influencing factors were found from the influencing factors of the culture medium, and a two-level factorial design was adopted. The experimental design, data analysis and response value optimization of this study were carried out using Design Expert 7.0 software.

[0081] The designed initial medium formula is (g / L): starch 14, glucose 28, soybean meal 20, corn steep liquor 26, sodium chloride 0.7, sodium nitrate 0.85, calcium carbonate 7, ammonium nitrate 2, ammonium sulfate 2.3, phosphoric acid Potassium dihydrogen 0.045.

[0082] According to previous experiments, starch, glucose, soybean cake powder, ammonium nitrate and ammonium sulfate are the key factors in the initial seed medium. Therefore, starch, glucose, soybean meal, ammonium nitrate and ammonium sulfate were selected as influencing factors for two-level factor design, and the contents of other compone...

Embodiment 2

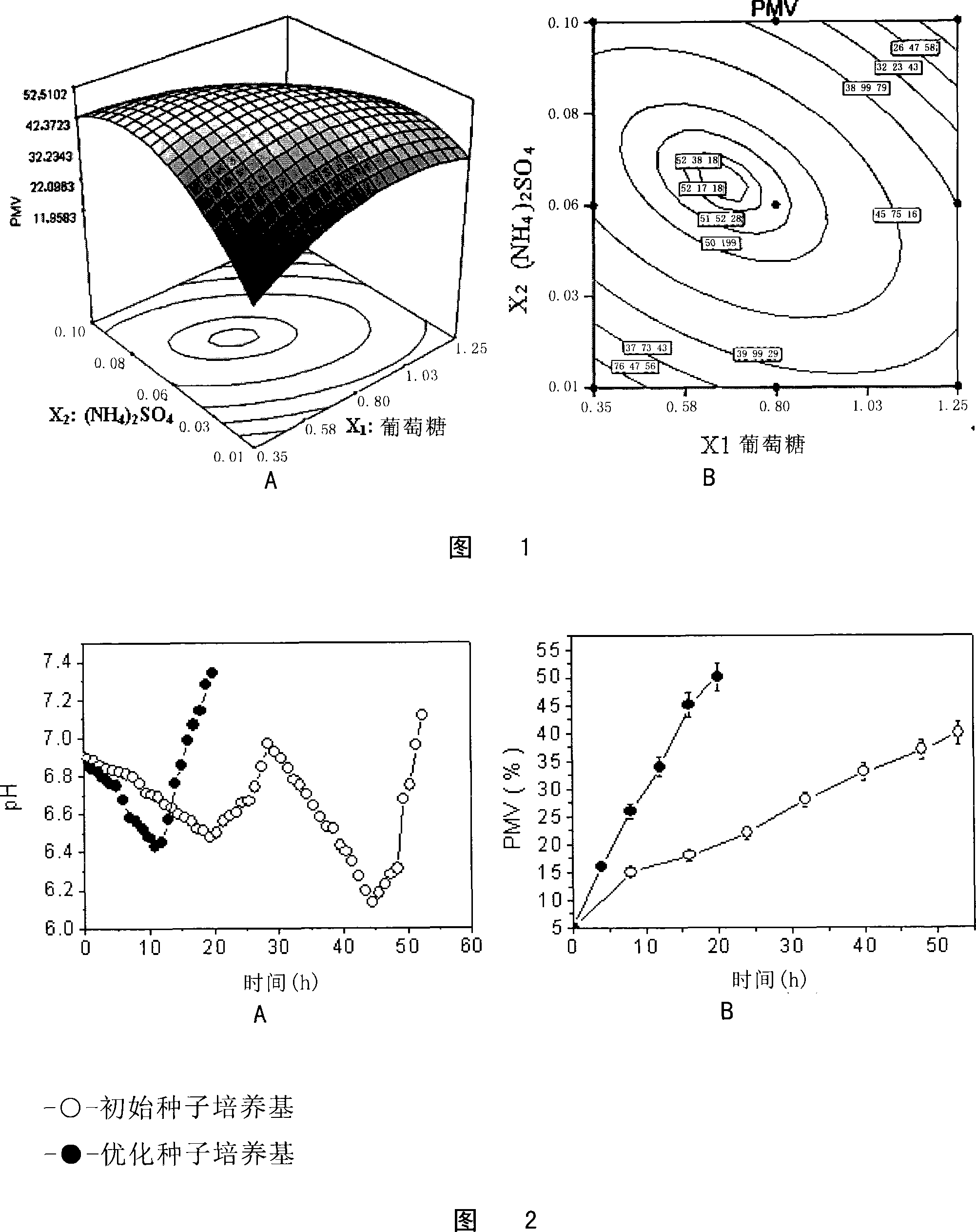

[0093] Embodiment 2 Response surface design (Response surface design)

[0094] Response surface design was carried out with glucose and ammonium sulfate as significant influencing factors, and the content (g / L) of other factors in each design group was the same, namely, starch 18.7, soybean meal powder 22.3, ammonium nitrate 1.33, corn steep liquor 26, calcium carbonate 7. Sodium chloride 0.7, potassium dihydrogen phosphate 0.045, sodium nitrate 0.85. The experimental design and analysis results are shown in Table 6-Table 10, respectively.

[0095] Table 6 Setting of variable high and low level values

[0096]

variable

Coded levels

-1

1

unit

glucose

ammonium sulfate

x 1

x 2

0.35

0.01

1.25

0.1

g / 30ml

g / 30ml

[0097] Table 7 Response surface design and experimental results

[0098]

run

factor

response

X 1

...

Embodiment 3

[0109] The preparation of embodiment 3 medium

[0110] The formulation of the culture medium is shown in Table 10.

[0111] Table 10

[0112] Medium 2

[0113] Method for preparing medium: Accurately weigh each component, mix each component, add appropriate amount of distilled water to dissolve, and constant volume, so that each component in the medium meets the ratio in the table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com