Two-dimensional ordered organic semiconductor composite nano membrane as well as special substrate and preparation method thereof

An organic semiconductor and thin film technology, which is applied in the field of two-dimensional ordered organic semiconductor composite nano-films and their special substrates and their preparation, can solve the problems of reducing the bulk properties of organic semiconductor materials, hindering the practical application of organic semiconductors, etc., and achieves a preparation method. Simple, low-cost, performance-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, preparation polymer dielectric ultra-thin film

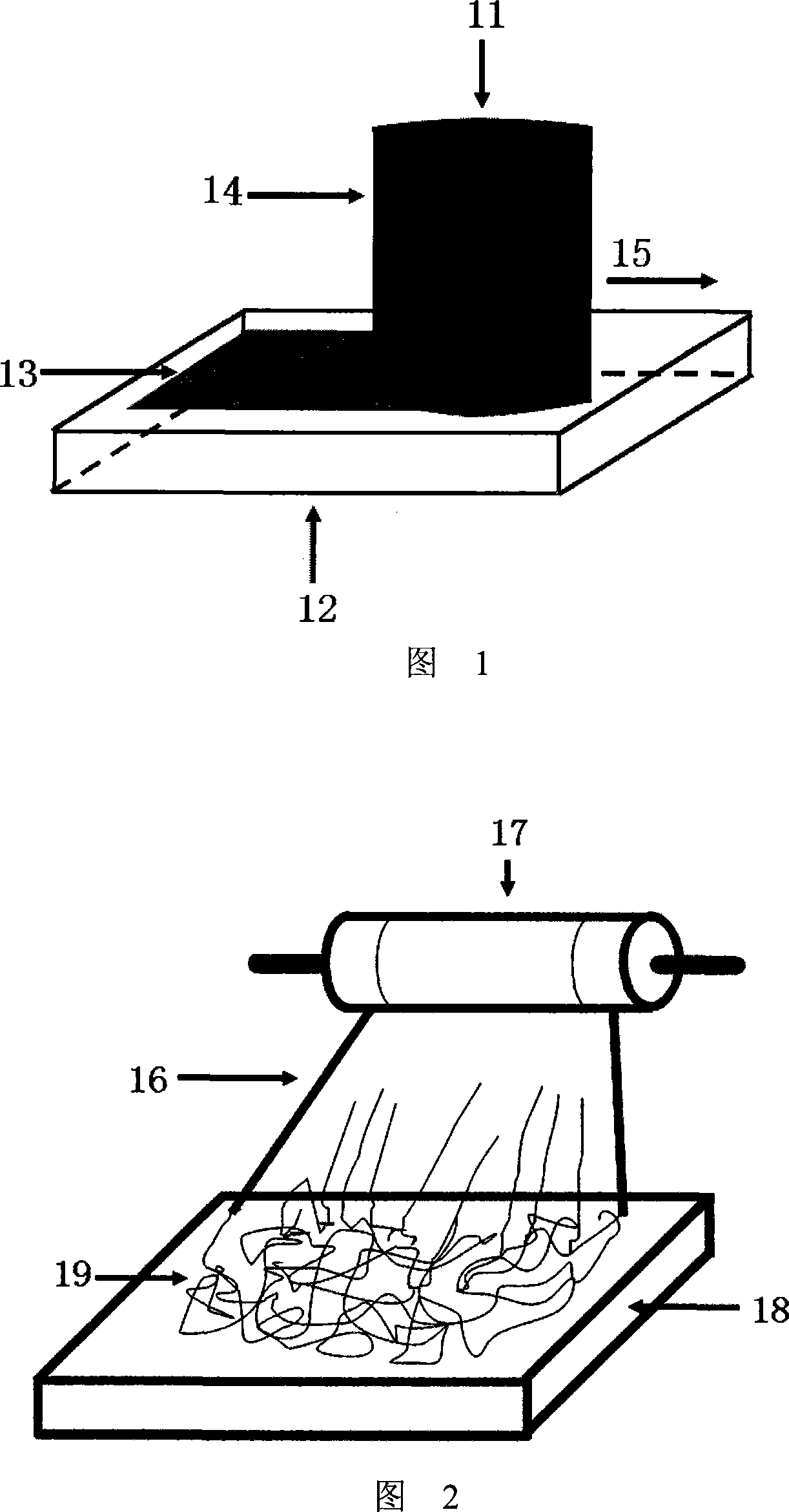

[0031] As shown in Figure 1, the method for preparing polytetrafluoroethylene (PTFE) dielectric ultra-thin film 13 by friction method is to preheat the glass substrate 12 (the glass substrate soaked in alkaline solution and cleaned with deionized water) to 280°C After that, apply a downward pressure 11 of 100N perpendicular to the glass substrate 12 to the polytetrafluoroethylene 14 placed on the glass substrate 12, and apply a uniform thrust of 10N along the horizontal direction, so that the polytetrafluoroethylene 14 is placed on the glass substrate 12 Extend horizontally at a speed of 15 cm / s to obtain an oriented polytetrafluoroethylene dielectric ultra-thin film 13 along the rubbing direction 15 .

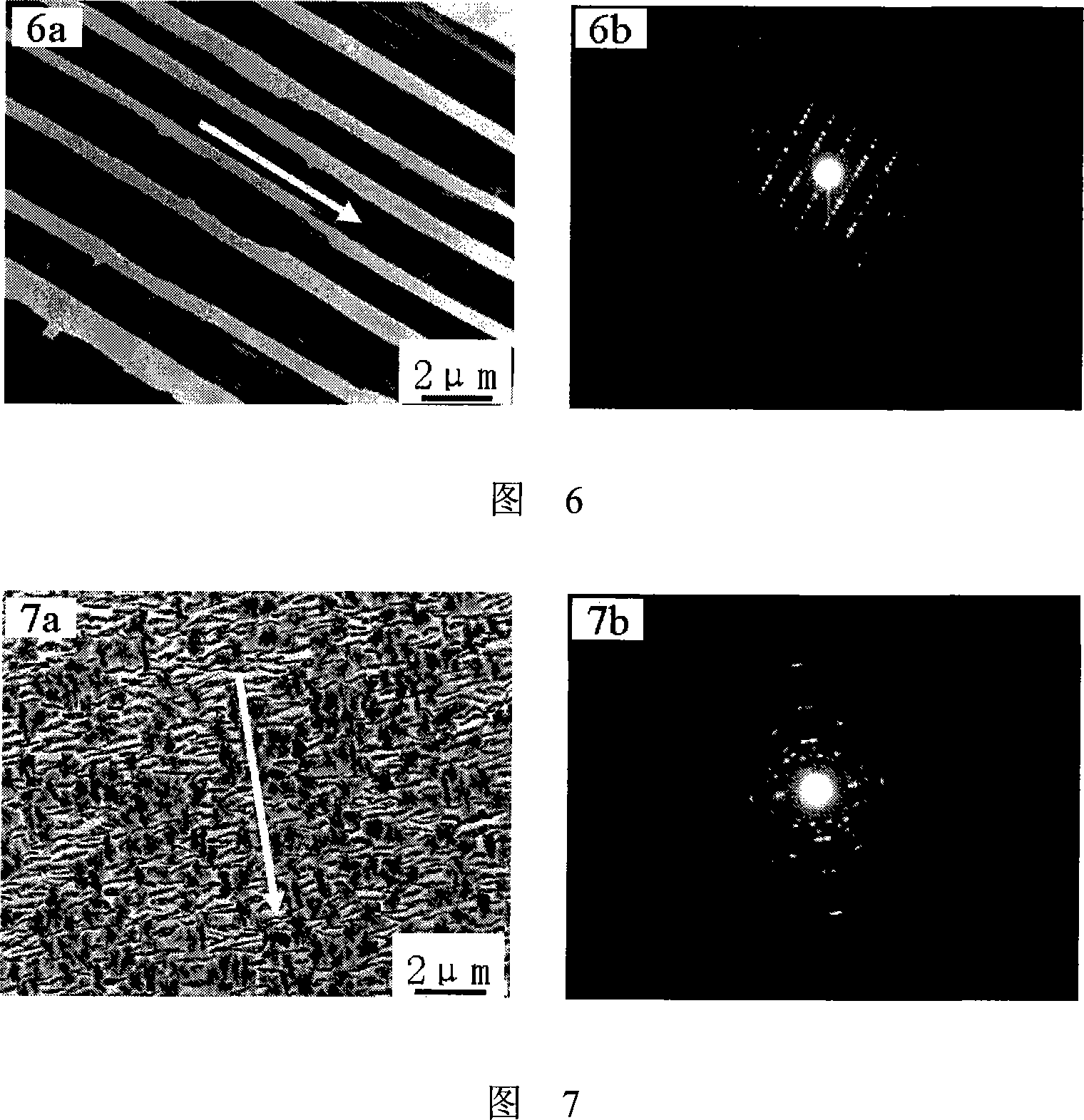

[0032] After measurement, it can be known that the thickness of the polytetrafluoroethylene dielectric ultra-thin film is about 60-120nm. Figure 3a and Figure 3b are the transmission electron microscope bri...

Embodiment 2

[0033] Embodiment 2, preparation polymer dielectric ultra-thin film

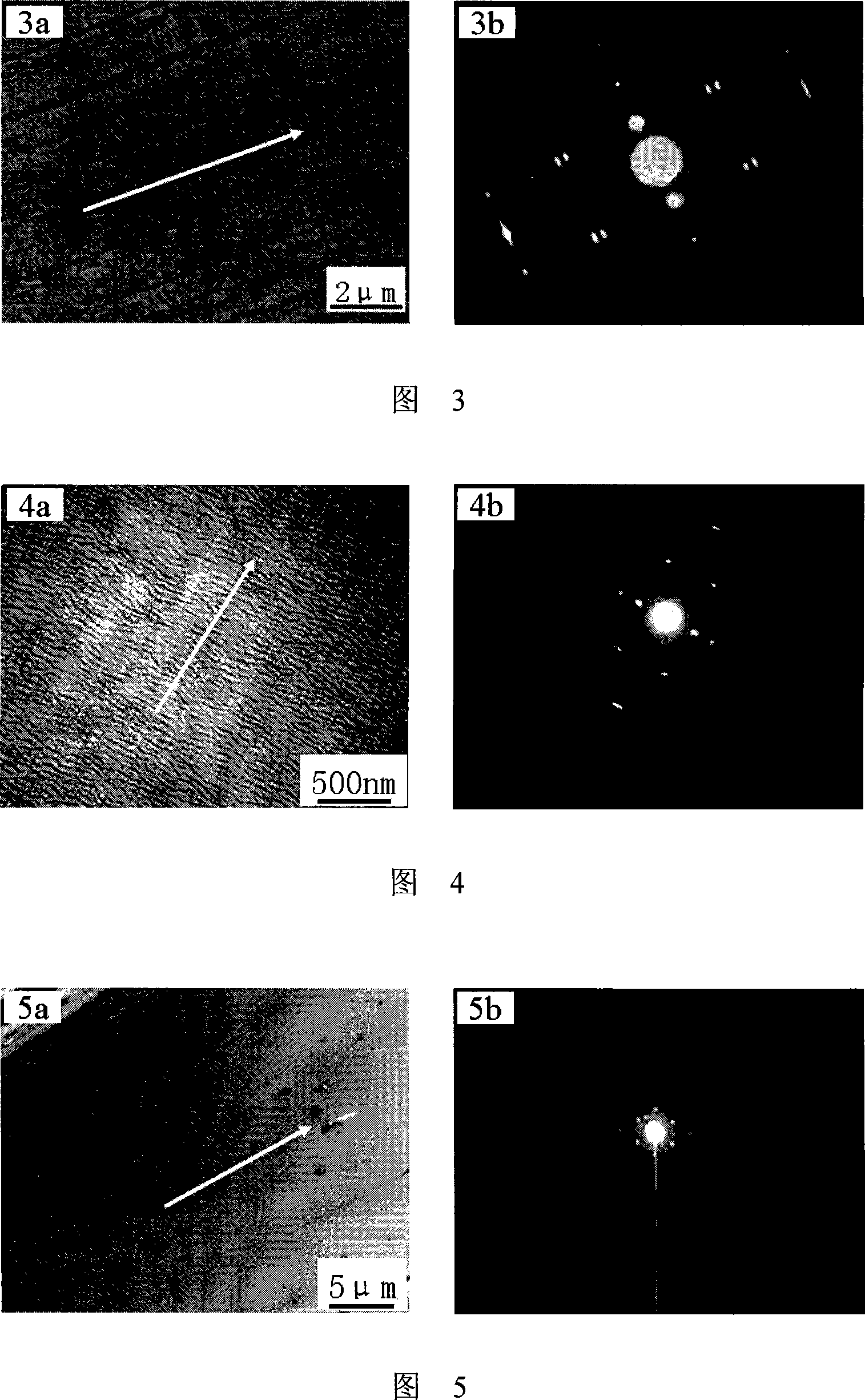

[0034] As shown in Figure 2, the method of preparing polymer dielectric ultra-thin films by melt stretching method is to mix polyethylene with xylene, heat and stir to fully dissolve, and prepare 0.5 grams of polyethylene per 100 milliliters of xylene homogeneous solution, and then evenly apply the homogeneous solution to the flat and smooth template 18 (glass plate) that has been preheated to 125 ° C. After the xylene is completely volatilized, a polyethylene melt film 19 is obtained. The mechanical roller 17 with adjustable rotating speed sticks the above-mentioned polyethylene melt film 19 and draws and stretches it; Attached to an alternate substrate (which is a silicon wafer). Wherein, the coefficient of friction of the mechanical roller used is 0.5.

[0035]After measurement, it can be known that the thickness of the polyethylene dielectric ultra-thin film is about 80-120nm. Figure 4a and Figure 4b ...

Embodiment 3

[0036] Example 3, preparation of two-dimensional ordered organic semiconductor composite nanofilm

[0037] The method for preparing a two-dimensional ordered organic semiconductor composite nano-film by the solution spin coating method provided by the present invention is to first prepare poly(2,5-dialkoxy-p-phenyleneethynylene) with a mass volume percentage concentration of 0.5 % (containing 0.5 g of poly(2,5-dialkoxy-p-phenyleneethynylene) per 100 ml of toluene) in 10 ml of toluene solution. At room temperature above-mentioned solution is spin-coated on the silicon chip substrate that has orientation polytetrafluoroethylene (PTFE) dielectric ultra-thin film that obtains by embodiment 1 again, and the spinning speed of film throwing machine is 2000 rev / mins, obtains that thickness is 50nm poly(2,5-dialkoxy p-phenyleneethynylene) organic semiconductor composite nano film.

[0038] Observing the microstructure of the above-mentioned organic semiconductor composite nano-film pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com