Polyester elastomer composition and method of making the same

A polyester elastomer and composition technology, applied in the chemical industry, can solve the problems of high and low temperature impact resistance and hydrolysis resistance, and achieve the effect of high low temperature impact resistance and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: According to the compounding proportion (unit: weight part) of No. 1 record in the table

[0049] Among them, the polyester elastomer is a resin formed by copolymerization of terephthalic acid, butylene glycol and polytetrahydrofuran ether glycol.

[0050] The epoxy compound is: bisphenol A epoxy resin E-51 (618).

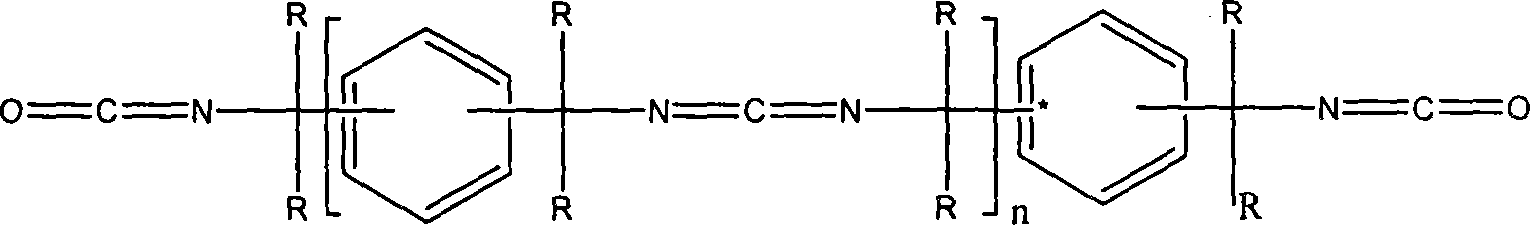

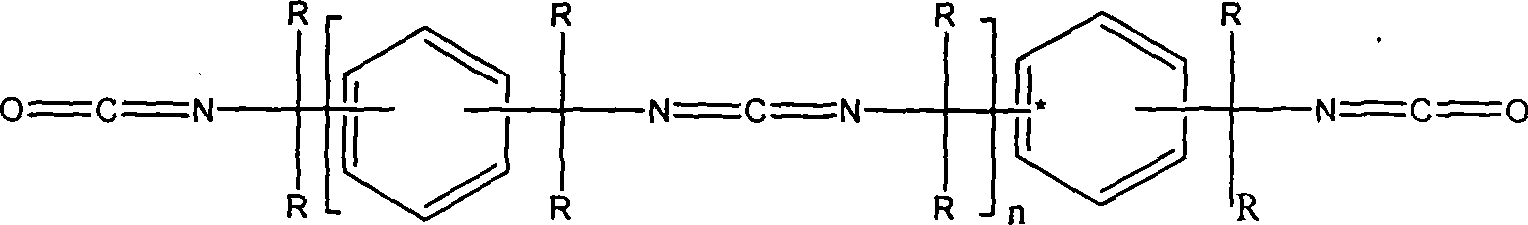

[0051] Polycarbodiimide: polycarbodiimide (molecular weight 1000)

[0052] Anhydride graft: pyromellitic dianhydride

[0053] Toughening polymer compound: polyolefin blend thermoplastic elastomer

[0054] Nucleating agent: aryl phosphate salt nucleating agent NA-11

[0055] Compatibilizer: Styrene maleic anhydride (SMA)

[0056] Antioxidant: Triphenyl Phosphite

[0057] Use a high-speed mixer to mix for 1 minute, and then use twin-screw extrusion to granulate. , sheared with a granulator to obtain granules of the polyester elastomer composition. The obtained pellets were dried at 120° C. for 5 hours while flowing nitrogen gas.

Embodiment 2

[0058] Embodiment 2: see No. 2 formula,

[0059] Among them: polyester elastomer is a resin formed by copolymerization of terephthalic acid, ethylene glycol and polytetrahydrofuran ether glycol,

[0060] The epoxy compound is: bisphenol F type epoxy resin epoxy equivalent 169

[0061] Polycarbodiimide: polycarbodiimide (molecular weight 1500)

[0062] Toughened polymer compound: polyolefin blended thermoplastic elastomer (TPO)

[0063] Antioxidant: Triphenyl Phosphite

[0064] Use a high-speed mixer to mix for 2 minutes, and then use a twin-screw extruder to granulate. Afterwards, it is sheared with a granulator to obtain granules of the polyester elastomer composition. The obtained pellets were dried at 120° C. for 5 hours while flowing nitrogen gas.

Embodiment 3

[0065] Embodiment 3: see No. 3 formula

[0066] According to the mixing ratio recorded in No. 3 in the table (unit: parts by weight)

[0067] Among them, the polyester elastomer is a resin formed by copolymerization of terephthalic acid, butylene glycol and polytetrahydrofuran ether glycol.

[0068] The epoxy compound is: bisphenol A epoxy resin E-51 (618).

[0069] Polycarbodiimide: polycarbodiimide (molecular weight 1000)

[0070] Antioxidant: Triphenyl Phosphite

[0071] Use a high-speed mixer to mix for 1 minute, and then use twin-screw extrusion to granulate. Afterwards, it is sheared with a granulator to obtain granules of the polyester elastomer composition. The obtained pellets were dried at 120° C. for 5 hours while flowing nitrogen gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com