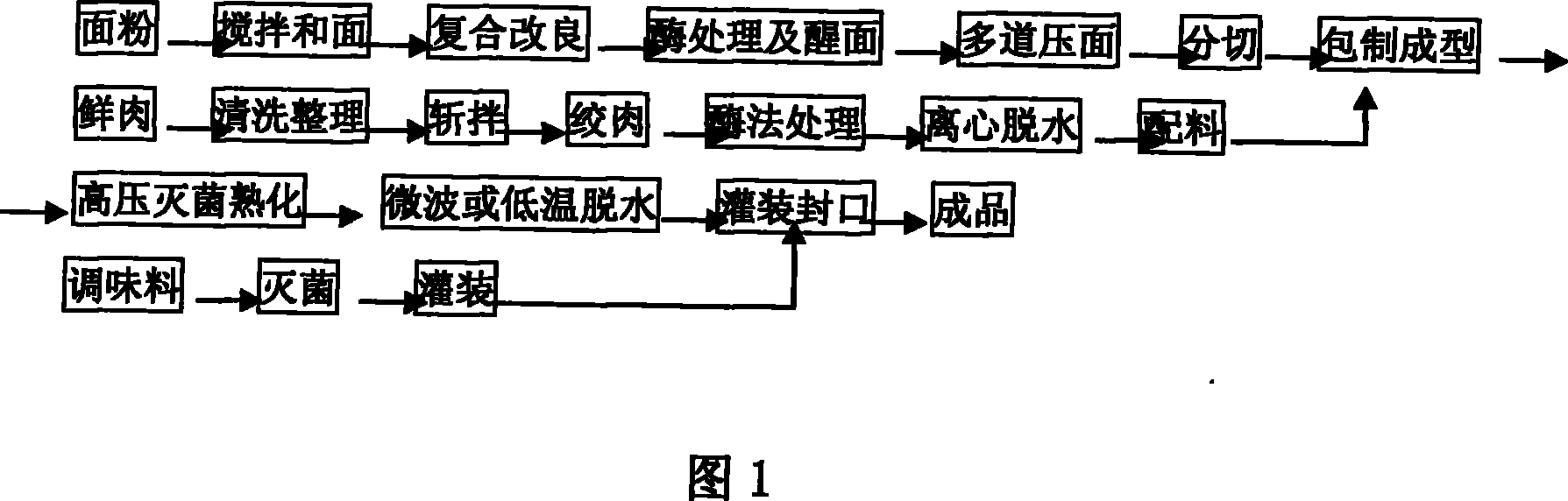

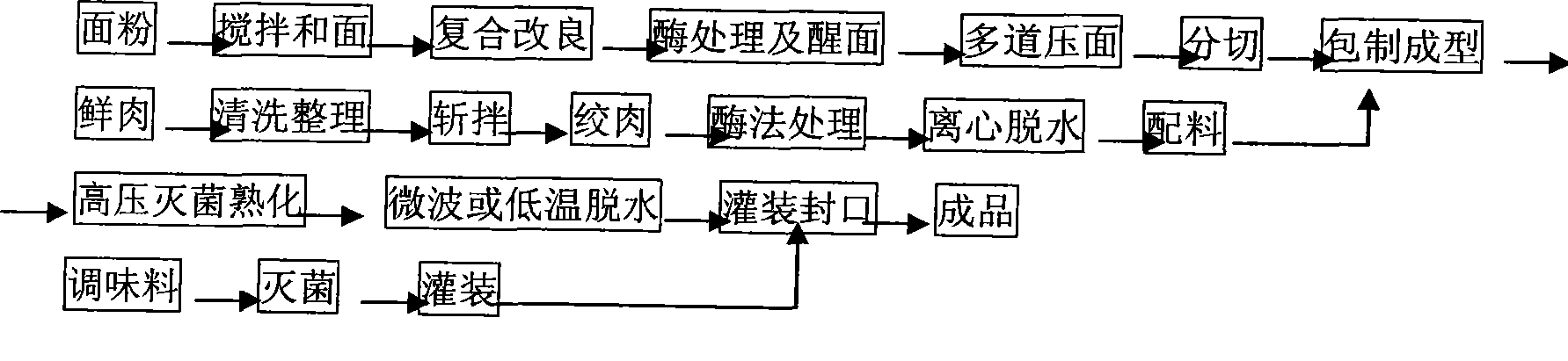

Processing method for processing convenient instant dewatered wonton and dumpling by enzyme method

A processing method and enzymatic treatment technology, which are used in food preparation, pre-baked dough treatment, baked food, etc., can solve the problems of loss of nutrients in meat filling, low production efficiency, protein denaturation, etc., and achieve short rehydration time and product quality. Low cost and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Enzymatic processing of dough (enzymatic treatment of gluten network structure): add 1750 grams of clean water to 5000 grams of wheat flour, and 0.025 grams of compound enzyme (by lipase, glucose oxidase and glutamine transaminase according to the ratio of 2:1:1) The weight ratio composition), 5 grams of compound emulsion stabilizers (tripolyglycerol monostearate, lecithin, sodium stearoyl lactylate, high acyl gellan gum and sodium caseinate by 1: 1: 1: 1: 2 weight ratio) mixed with 5 grams of compound salt (composed of potassium carbonate, sodium carbonate and sodium chloride in a weight ratio of 1:2:2), supplemented with appropriate amount of animal and vegetable protein, vitamins and other ingredients (Note: animal and plant Protein and vitamins can be added in moderation as needed). After mixing for 2 minutes by a high-speed flour milling machine, knead the dough by a single-speed or double-speed dough mixer for 5-20 minutes, keep warm at 15-50°C, and treat with ...

Embodiment 2

[0041] 1. Enzymatic processing of dough (gluten network structure enzymatic treatment): add 2250 grams of clean water to 5000 grams of wheat flour, 22.5 grams of compound enzyme (by lipase, glucose oxidase and glutamine transaminase according to the ratio of 6:4:4 composition by weight ratio), 225 grams of compound emulsion stabilizer (by tripolyglycerol monostearate, lecithin, sodium stearoyl lactylate, high acyl gellan gum and sodium caseinate by 4:4:3:4: 6 weight ratio) and 225 grams of compound salts (composed of potassium carbonate, sodium carbonate and sodium chloride in a weight ratio of 3:4:6), mixed, supplemented with appropriate amounts of animal and vegetable protein, vitamins and other ingredients. After being beaten and stirred by a high-speed flour machine for 2 to 10 minutes, the dough is kneaded by a single-speed or double-speed dough mixer for 5 to 20 minutes, kept at 15 to 50°C, and treated with compound enzymes for 20 to 60 minutes (to complete the enzymatic ...

Embodiment 3

[0049] 1. Enzymatic processing of dough (enzymatic treatment of gluten network structure): add 1850 grams of clean water to 5000 grams of wheat flour, and 12.5 grams of compound enzyme (by lipase, glucose oxidase and glutamine transaminase by 4: 2: 3 weight ratio), 100 grams of compound emulsion stabilizer (by three polyglycerol monostearate, lecithin, sodium stearoyl lactylate, high acyl gellan gum and sodium caseinate by 2: 3: 1~3 : 3: 4 weight ratio), 80 grams of compound salts (composed of potassium carbonate, sodium carbonate and sodium chloride in a weight ratio of 2: 3: 5), mixed with appropriate amount of animal and vegetable protein, vitamins and other ingredients. After being beaten and stirred by a high-speed flour machine for 2 to 10 minutes, the dough is kneaded by a single-speed or double-speed dough mixer for 5 to 20 minutes, kept at 15 to 50°C, and treated with compound enzymes for 20 to 60 minutes (to complete the enzymatic reorganization of the gluten network ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com