Method for preparing nano-micrometre composite microsphere

A kind of composite microsphere and nanotechnology, which is applied in the field of preparation of nano-micron composite microspheres, can solve the problems of poor stability, limit the application and lifespan of nano-micron composite microspheres, and achieve the effect of improving application and lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

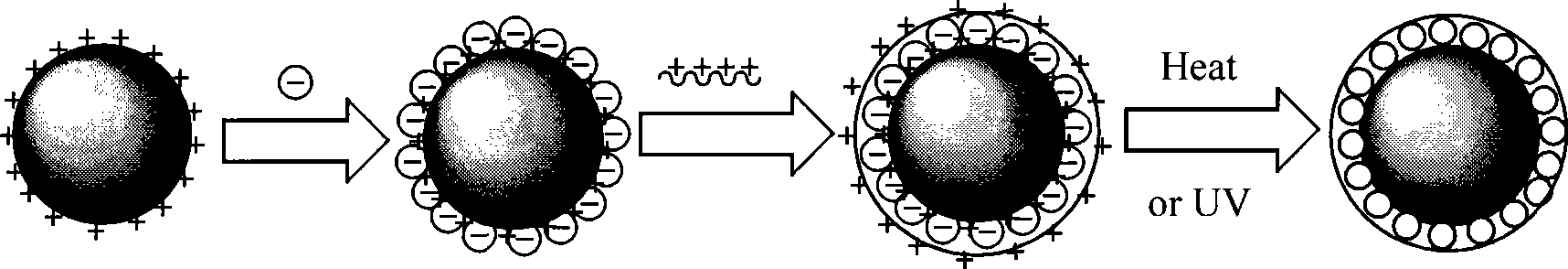

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Synthesis of monodisperse latex particles P (St-MMA-MAA) with negatively charged surfaces:

[0033] 0.4g of ammonium persulfate, 0.8g of ammonium bicarbonate and a certain amount of methacrylic acid (0.05-0.6g) were dissolved in 10mL of deionized water (solution A). Take 22.5mL of styrene, 1.25mL of methyl methacrylate, and 110mL of deionized water in a 250mL three-necked flask, mix and stir, pass N 2 protection. When the temperature of the liquid in the bottle rises to 70°C, quickly add solution A to the mixed liquid in the bottle. Stirring was maintained at 70°C for 8 hours to obtain a homogeneous emulsion.

Embodiment 2

[0034] Example 2: Synthesis of monodisperse microspheres with negatively charged sulfonic acid functional groups on the surface:

[0035] Add 10 grams, 5 microns, and a degree of cross-linking of 55%, monodisperse polystyrene / divinylbenzene microspheres to 50 grams of concentrated sulfuric acid, then heat to 120 degrees and maintain this temperature for 10 hours. The microspheres are separated by filtration, centrifugation, etc. The surface of the prepared microspheres has negatively charged sulfonic acid functional groups.

Embodiment 3

[0036] Example 3: Synthesis of monodisperse microspheres with positively charged carboxyl functional groups on the surface:

[0037] Add 10 grams, 5 microns, cross-linking degree of 10%, monodisperse polystyrene / divinylbenzene microspheres into the dichloroethane solvent, add chloromethyl fan under the protection of nitrogen, and react for 5 hours. The microspheres prepared after filtration have chloromethyl functional groups on the surface. These microspheres react with ammonia to prepare amino microspheres with positive charges on the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com