Method for preparing low molecular weight narrow distribution brominated polystyrene by active/controllable polymerization

A brominated polystyrene, low molecular weight technology, used in fire-resistant coatings, etc., can solve the problems of high molecular weight, unstable product quality, and poor compatibility with matrix resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

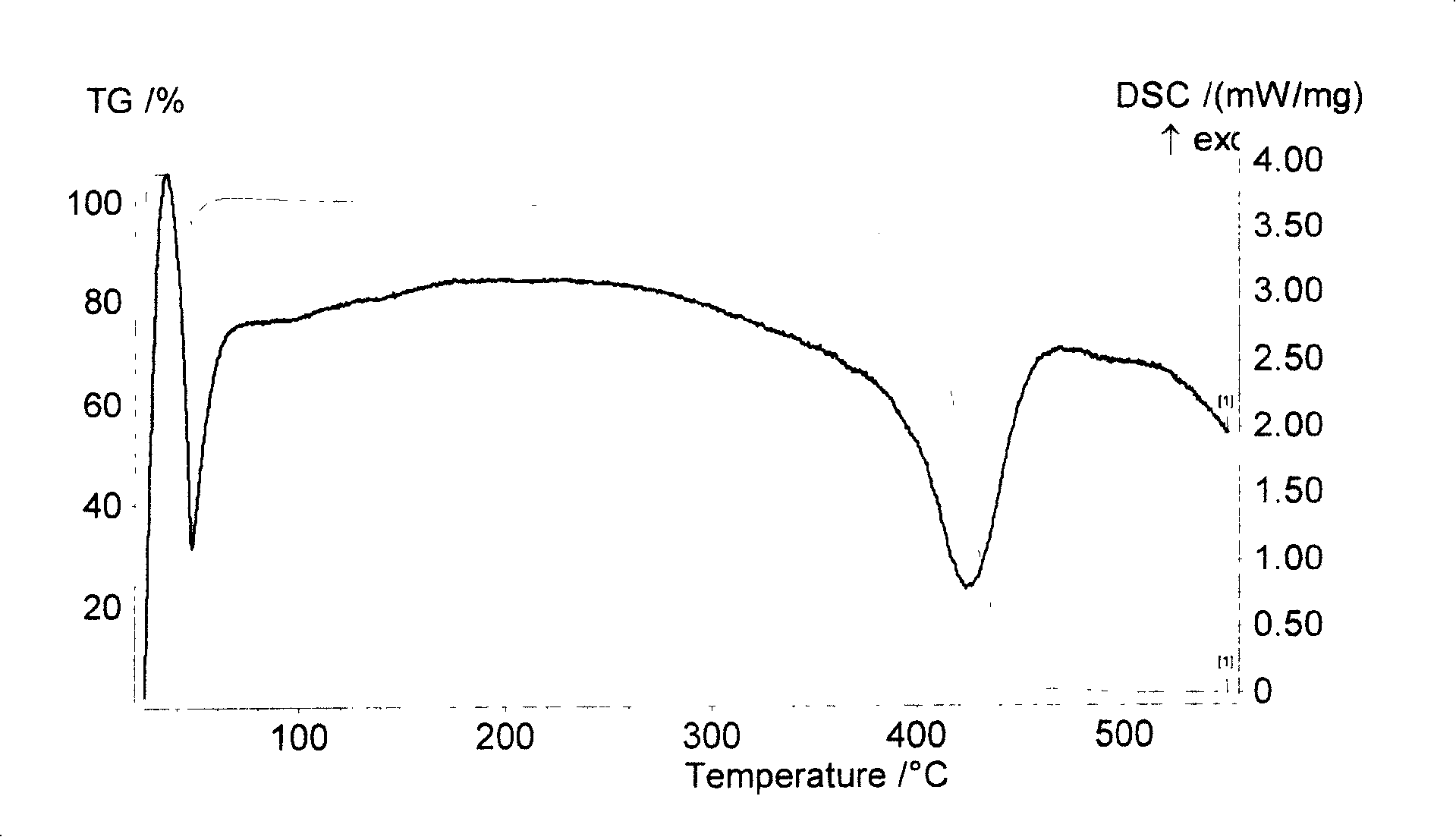

[0038] Styrene is used as a monomer, organic halides containing halogen atoms are used as initiators, low-valent metal halides are used as catalysts and ligands, and low-molecular-weight polystyrene is obtained by performing atom transfer free radical polymerization. Low-molecular-weight polystyrene uses alkyl halide as a solvent and alkylaluminum halide as a catalyst. In the presence of a dehydrating agent, low-molecular-weight polystyrene is brominated with bromine to obtain low-molecular-weight brominated polystyrene.

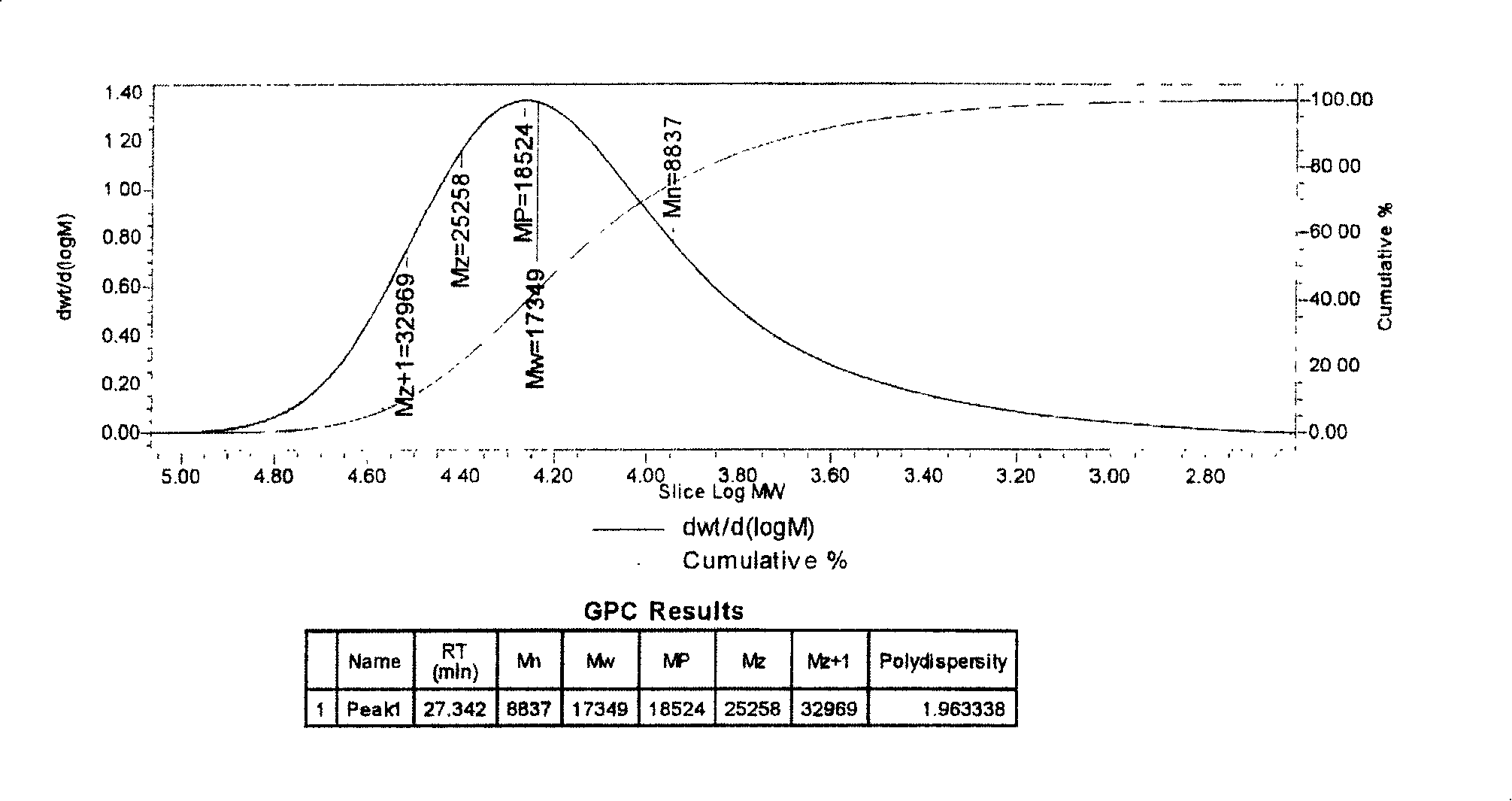

[0039] Step (a): Add refined 50g styrene, 0.05g α-methyl bromoacrylate, 0.05g cuprous chloride and 0.1g bipyridine in a 250mL three-necked flask equipped with a magnetic stirrer, and react The system was evacuated and filled with nitrogen, heated to 80°C, stirred by magnetic force and reacted under reflux for 20h. After the obtained product was dissolved in tetrahydrofuran, it was added dropwise to a precipitant with a ratio of 1:10 of methanol and distilled...

Embodiment 2

[0043] Styrene is used as a monomer, organic halides and azos containing halogen atoms are used as initiators, high-valent metal halides are used as catalysts and ligands, and low molecular weight polystyrene is obtained by reverse atom transfer radical polymerization. Low-molecular-weight polystyrene uses alkyl halide as a solvent and alkylaluminum halide as a catalyst. In the presence of a dehydrating agent, low-molecular-weight polystyrene is brominated with bromine to obtain low-molecular-weight brominated polystyrene.

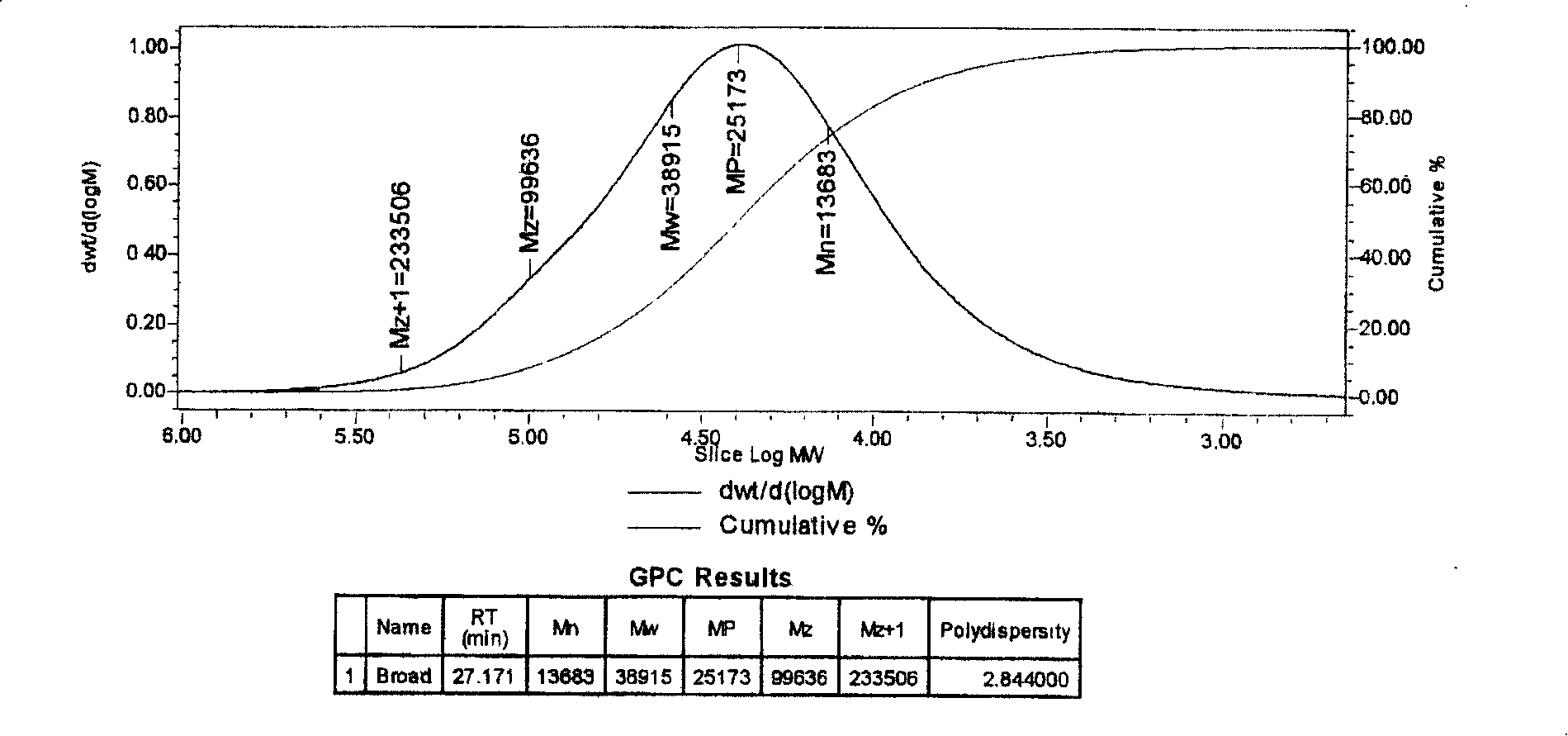

[0044] Step (a): Add refined 40g styrene, 0.05g benzyl chloride, 0.02g azobisisobutyronitrile, 0.08g ferric chloride and 0.05g triphenyl to a 250mL three-necked flask equipped with a magnetic stirrer Based phosphine, the reaction system was evacuated and filled with nitrogen, heated to 120 ° C, magnetically stirred and refluxed for 30 h. After the obtained product was dissolved in tetrahydrofuran, it was added dropwise to a precipitant with a ratio of meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decomposition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com