A non symmetric water natrium/kalium ion battery capacitor

A potassium ion, asymmetric technology, applied in the direction of electrolytic capacitors, capacitors, battery electrodes, etc., can solve the problem of low energy storage density of capacitors, and achieve the effects of high power, safe use, high specific capacity and specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

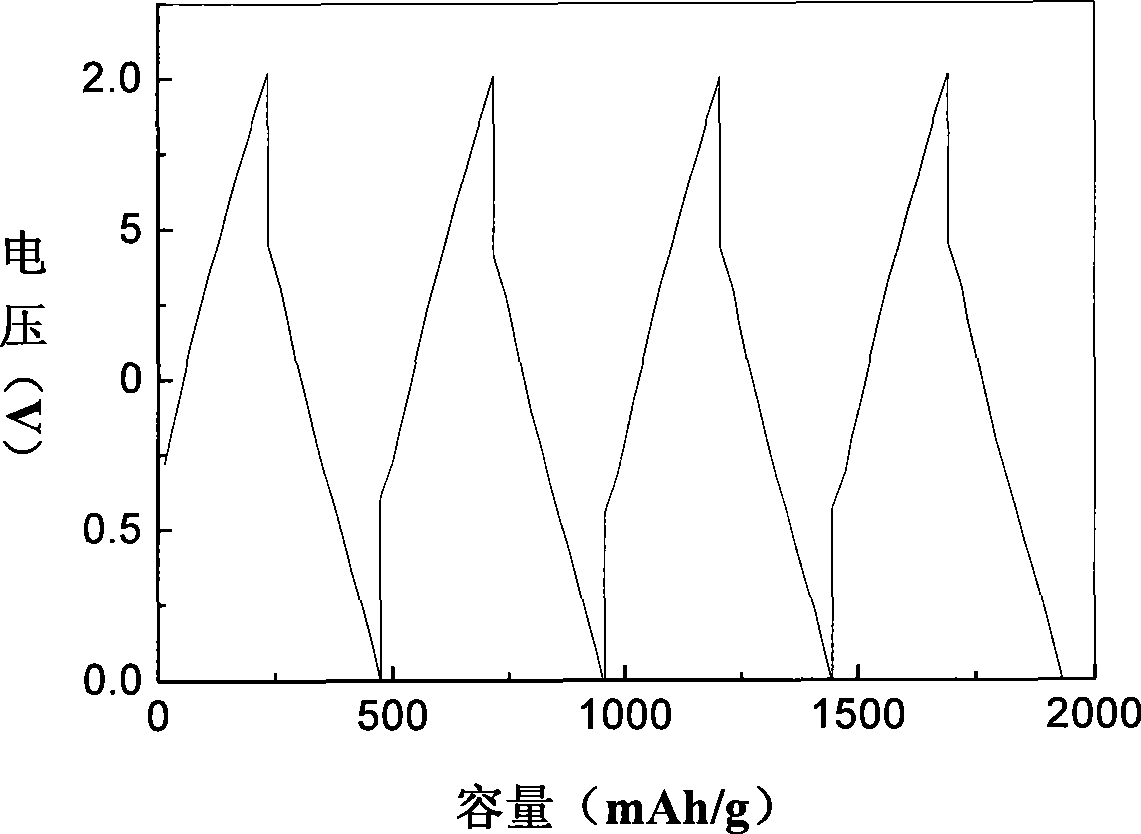

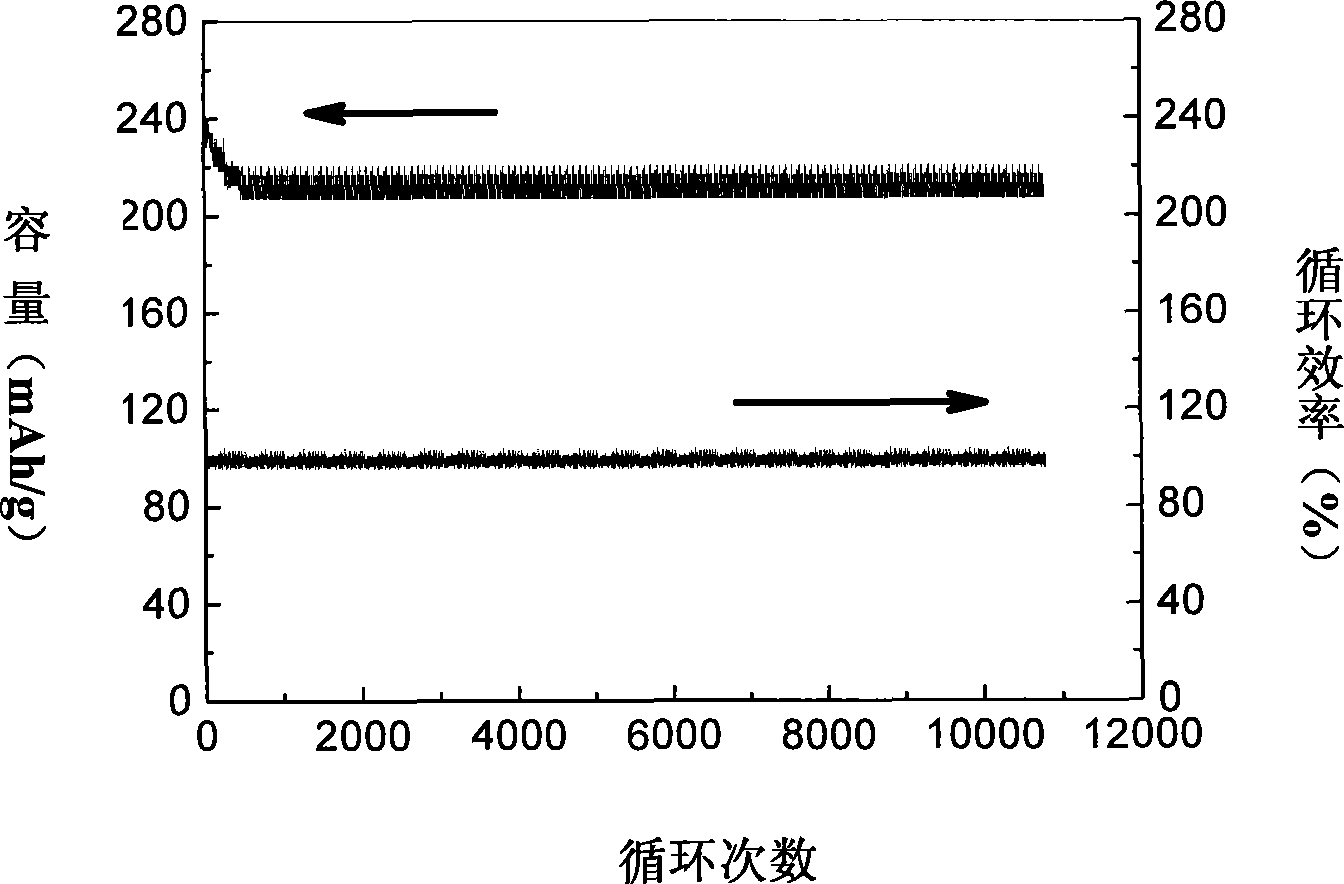

[0018] The positive electrode material is NaMnO synthesized by solid phase method 2 . Positive plate composition according to NaMnO 2 : carbon black: binder = 8: 1: 1 weight ratio mixed evenly, coated on the nickel mesh current collector, dried and pressed into electrodes. The negative electrode material is commercial activated carbon, and the negative electrode slurry is mixed according to the ratio of activated carbon: conductive agent: binder = 8:1:1, and then evenly coated on the nickel mesh current collector, dried and pressed into an electrode. Use non-woven fabrics for commercial alkaline manganese batteries as separators, use 0.5MNa 2 SO 4 The aqueous solution is used as an electrolyte and assembled into a battery. The discharge current between 0~2V is 30C, and the charge and discharge curve is as attached figure 1 As shown, the capacity of the battery is 240mAh, and the capacity retention rate after 10,000 cycles can be 89% (see attached figure 2 ).

Embodiment 2

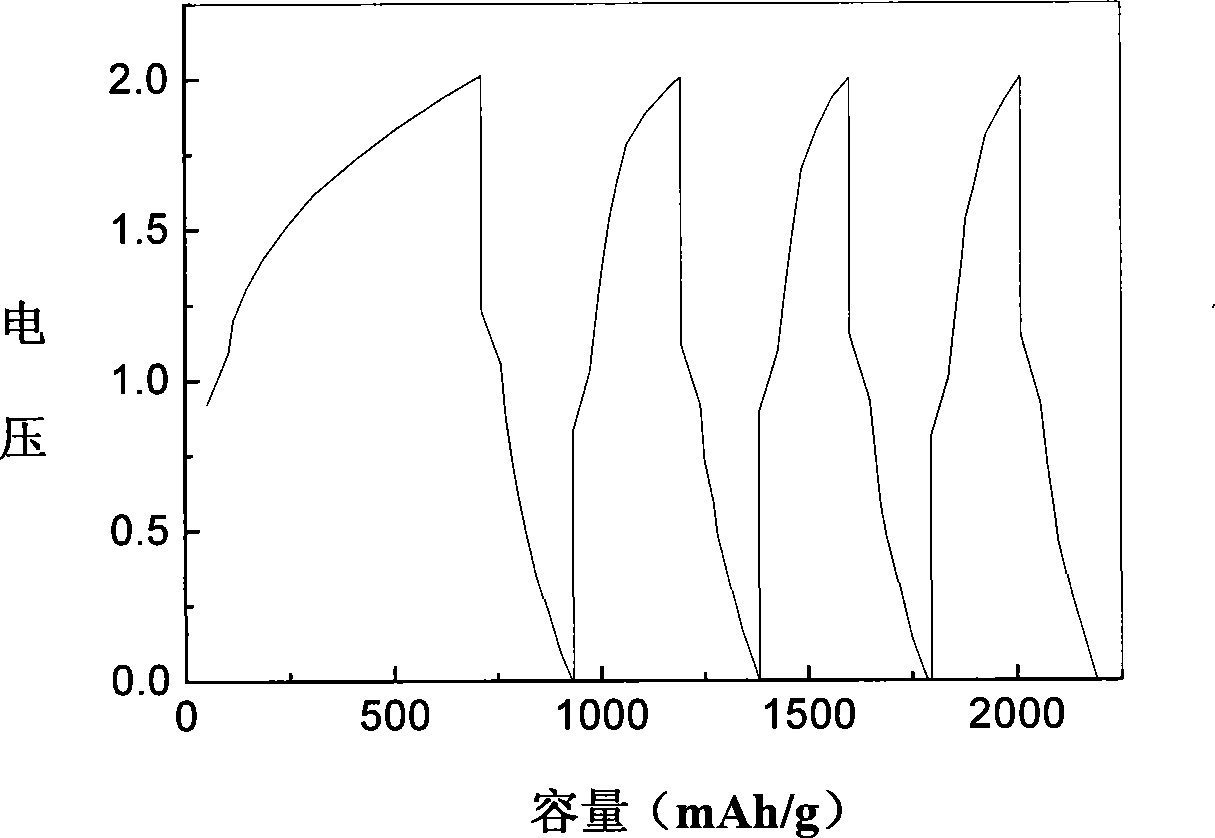

[0020] The cathode material is made of synthetic NaCoO 2 . Positive sheet composition according to NaCoO 2 : carbon black: binder = 8: 1: 1 weight ratio mixed evenly, coated on the nickel mesh current collector, dried and pressed into electrodes. The negative electrode material is commercial activated carbon, and the negative electrode slurry is mixed according to the ratio of activated carbon: conductive agent: binder = 8:1:1, and then evenly coated on the nickel mesh current collector, dried and pressed into an electrode. Using non-woven fabric as the diaphragm, with 0.5M Na 2 SO 4 The solution acts as an electrolyte and is assembled into a battery. The discharge current between 0~2V is 30C, the discharge capacity of the battery is 220mAh, the charge and discharge curve is as attached image 3 As shown, the capacity retention rate of 10,000 cycles can be 91%.

Embodiment 3

[0022] The cathode material is made of synthetic NaV 3 o 8 . Positive sheet composition according to NaV 3 o 8 : carbon black: binder = 8: 1: 1 weight ratio mixed evenly, coated on the nickel mesh current collector, dried and pressed into electrodes. The negative electrode material is commercial activated carbon, and the negative electrode slurry is mixed according to the ratio of activated carbon: conductive agent: binder = 8:1:1, and then evenly coated on the nickel mesh current collector, dried and pressed into an electrode. Using non-woven fabric as the diaphragm, with 0.5M Na 2 SO 4 The aqueous solution is used as an electrolyte and assembled into a battery. The discharge current between 0~2V is 30C, the capacity of the battery is 200mAh, and the capacity retention rate can be 83% after 10,000 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com