Modified chitosan crosslinked resin for defluorination in water and method of preparing the same

A technology of chitosan cross-linking and chitosan, which is applied in the field of resin, can solve the problems of unutilized water defluorination application, aluminum plate electrode passivation, and large power consumption, and achieve stable defluorination effect, simple regeneration, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the preparation of resin

[0025] Mix 1g of chitosan and 25ml of acetic acid to prepare chitosan acetate sol, add 75ml of liquid paraffin and 3.7ml of 0.2mol / L ferric chloride solution to the above reaction system and stir at a stirring speed of 160-220r / min , then add 1.5ml glutaraldehyde solution, raise the temperature to 40°C, react for 1h, adjust the pH value to 9-10 with dilute lye, then raise the temperature to 60-70°C for 4h, cool and filter with suction. Wash with petroleum ether, acetone, and ethanol three times in sequence, and finally wash with water until neutral, vacuum filter, and dry to obtain 1.72 g of iron-modified chitosan cross-linked resin.

Embodiment 2

[0026] Embodiment 2: Adopting chitosan cross-linked resin to treat fluorine-containing water

[0027] The chitosan cross-linked resin was the product of Example 1, the test environment temperature was 25°C, the pH of the fluorine-containing water was 6.8, and the fluorine-containing water was prepared by itself with a concentration of 2.0 mg / L.

[0028] Get the iron-modified chitosan cross-linked resin 0.5g prepared in Example 1 and mix it with 50ml fluorine-containing water for 12h, then filter, and measure the fluoride ion content in the filtrate to be 0.186mg / L. The analysis results show that the removal rate of chitosan cross-linked resin to fluoride ion can reach more than 80%.

Embodiment 3

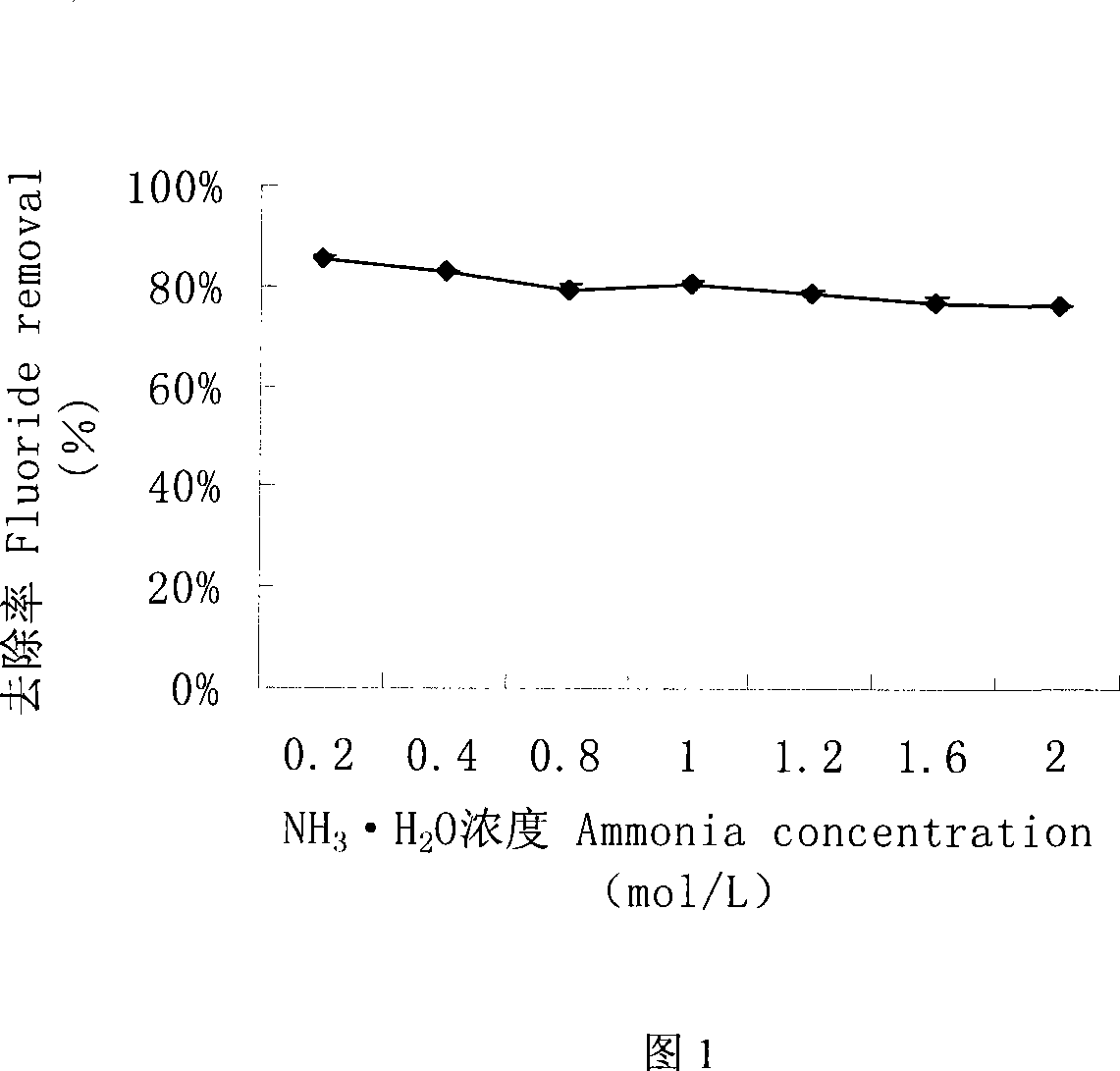

[0029] Example 3: Regeneration of chitosan cross-linked resin and its effect of removing fluoride in water

[0030] The chitosan cross-linked resin adsorbed in Example 2 was regenerated with different concentrations of ammonia, and then used for defluorination. The results are shown in Figure 1: the resin was regenerated with 0.2mol / L ammonia, and the effect was the best.

[0031] Get the above-mentioned adsorbed 0.2mol / L ammonia regeneration resin, regenerate twice continuously with 0.2mol / L ammonia, and then use it for defluorination. The removal rate of fluoride can still reach more than 80%, and the fluoride content in the filtrate is measured as : 0.187mg / L and 0.187mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com