Method for manufacturing solid electrolyte membrane electrode

A solid electrolyte membrane and solid electrolyte technology, applied in solid electrolyte fuel cells, battery electrodes, electrolysis process, etc., can solve the problems of increased catalyst utilization, low catalyst utilization, fuel diffusion loss, etc., to achieve excellent stability, The effect of increasing the electrochemical reaction area and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A kind of preparation method of solid electrolyte membrane electrode provided by the present invention, its specific process steps are as follows:

[0023] 1) Preparation of a solution or mixture of solid electrolyte materials: mixing the solid electrolyte material and a dispersant to prepare a mixture or solution with a mass percentage of 0.1%-70%, wherein the dispersant is water, ethanol or isopropanol; the The solid electrolyte membrane material is an inorganic solid ion exchange material or an organic ion exchange material or an inorganic and organic doped composite material.

[0024] 2) Use a spray pen or spray gun dispersion equipment to spray the mixture or solution evenly on both sides of the solid electrolyte membrane to form a solid electrolyte membrane loaded with solid electrolyte materials; when spraying with a spray gun or spray gun, the relative pressure of the gas is controlled at 0.1- Between 1.0MPa; spraying speed is 0.02-500ml.min -1 .cm -2 . The t...

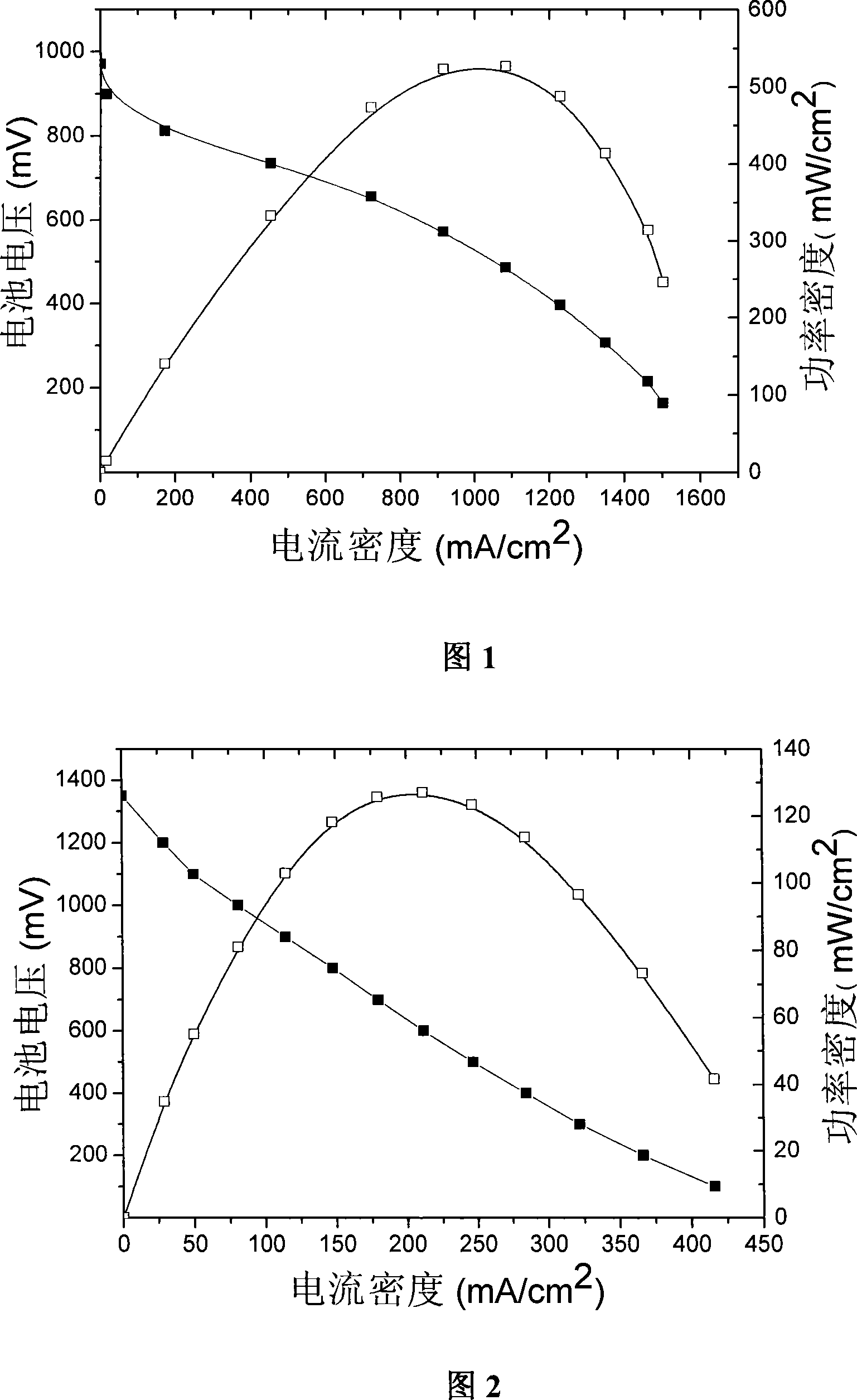

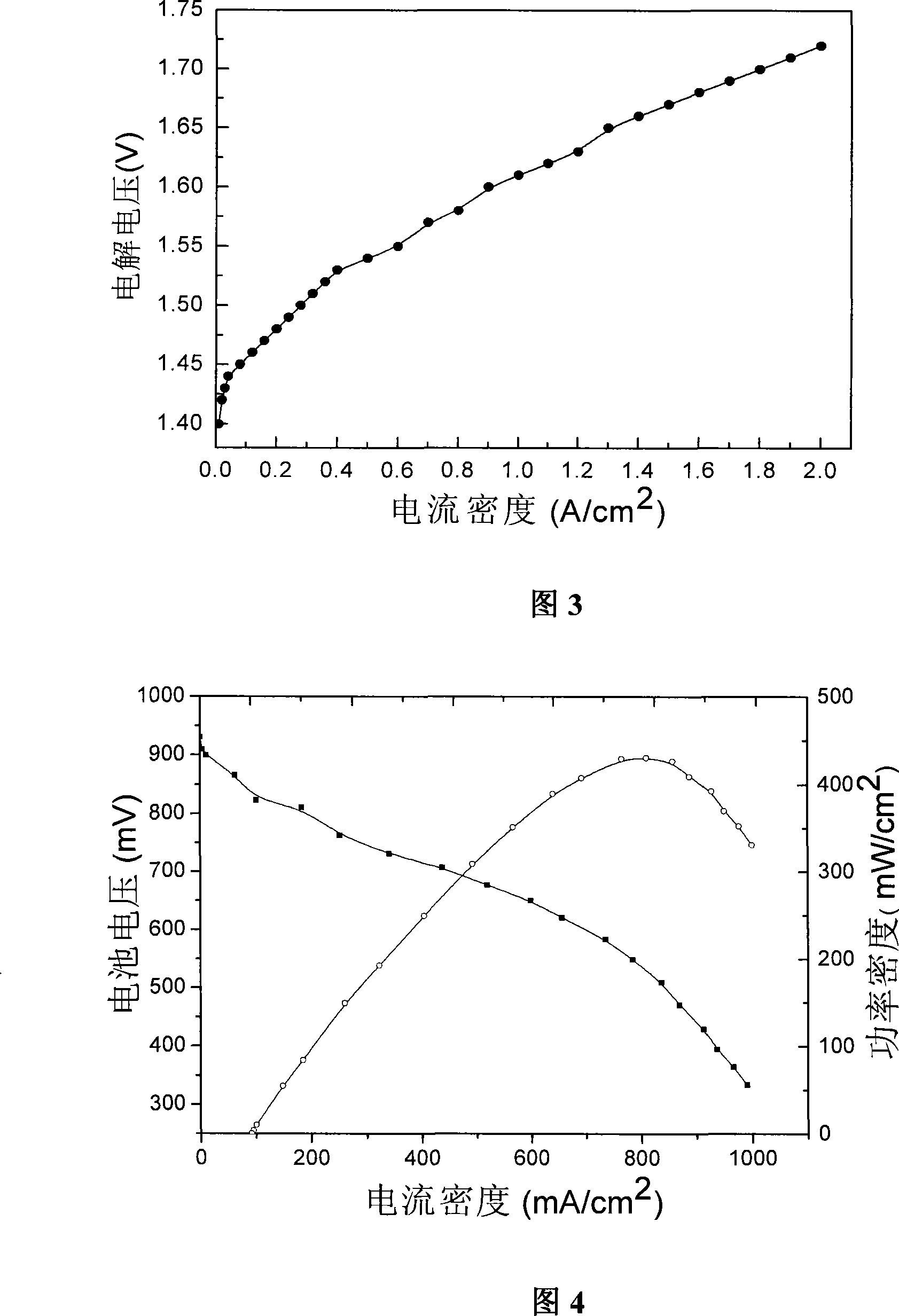

Embodiment 1

[0031] Weigh a perfluorosulfonic acid resin solution with a mass percent content of 5%, add a certain amount of isopropanol and a small amount of water, and mix uniformly by ultrasonic to prepare a perfluorosulfonic acid resin solution with a mass percent content of 0.1%. The spray gun uses nitrogen with a relative pressure of 0.1MPa as the carrier gas, and takes 0.1ml.min -1 .cm -2 The speed is sprayed on the proton exchange membrane with a thickness of 50 microns, and the control load is 0.6mg / cm 2 . The weighed Pt / C (40%) catalyst, 5% perfluorosulfonic acid resin and isopropanol make the mass ratio of Pt / C catalyst: perfluorosulfonic acid resin: isopropanol 1: 10: 500, ultrasonic Shake for 8 minutes to form the catalyst solution to be sprayed, take 1.000g of the solution in 500ml.min -1 .cm -2 Spray-coated on the proton exchange membrane with perfluorosulfonic acid resin layers on both sides, at the same time, soak commercial carbon paper in 30% PTFE emulsion for 1 minu...

Embodiment 2

[0033] Weigh 0.500g of Pt / C (containing 40%Pt) catalyst, 1.000g of 5% perfluorosulfonic acid resin and 1.000g of isopropanol solution, so that Pt / C catalyst: perfluorosulfonic acid resin: isopropanol The mass ratio is 1:0.1:2. Ultrasound for 8 minutes to form a catalyst ink-like substance to be sprayed, use a spray pen with air at a relative pressure of 0.1MPa as the carrier gas, and use 0.02ml.min -1 .cm -2 The speed is directly sprayed on the proton exchange membrane with a thickness of 25 microns. At the same time, commercialized carbon paper was soaked in 20% PTFE emulsion for 5 minutes, and then placed in a 340°C muffle furnace for sintering for 60 minutes to form hydrophobic carbon paper, and the carbon powder paste containing 20% PTFE was coated on On the carbon paper with hydrophobic treatment, the coating carbon powder load is 1.0mg / cm 2 , and finally the gas diffusion layer coated with carbon powder and the proton exchange membrane sprayed with a perfluorosulfon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com