Composite electrode and method for preparing high purity polyaniline nanometer line

A composite electrode, polyaniline technology, applied in capacitor electrodes, electrode shapes/types, circuits, etc., can solve the problems of low yield, low product purity, and low purity of polyaniline nanowires, and achieve simple process and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

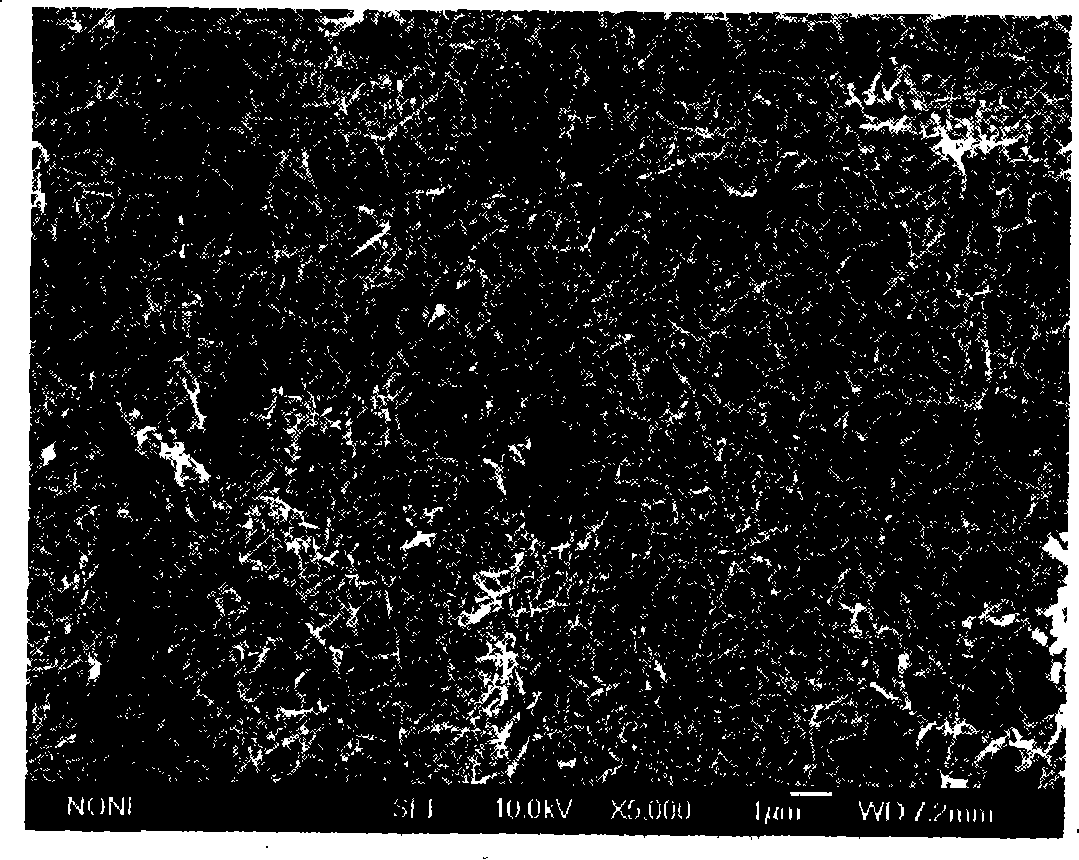

[0013] 0.629 g of polysulfone was dissolved in 6 mL of N,N-dimethylacetamide to obtain a N,N-dimethylacetamide solution containing 10% polysulfone. Then coat a film on the surface of the stainless steel electrode to control the thickness of the liquid film to 5 μm. Afterwards, the stainless steel electrode coated with polysulfone N, N-dimethylacetamide solution was quickly immersed in a coagulation bath (water) to complete phase inversion, and a polysulfone / stainless steel composite electrode was obtained. The polysulfone / stainless steel composite electrode was used as the working electrode, and another piece of stainless steel was used as the counter electrode. -1 Aniline and 1.00mol·L -1 Sulfuric acid was used as the electrolyte, and a cell voltage of 1.80V was used for electrolytic polymerization for 40 minutes to obtain polyaniline nanowires, the purity of which was 100%.

Embodiment 2

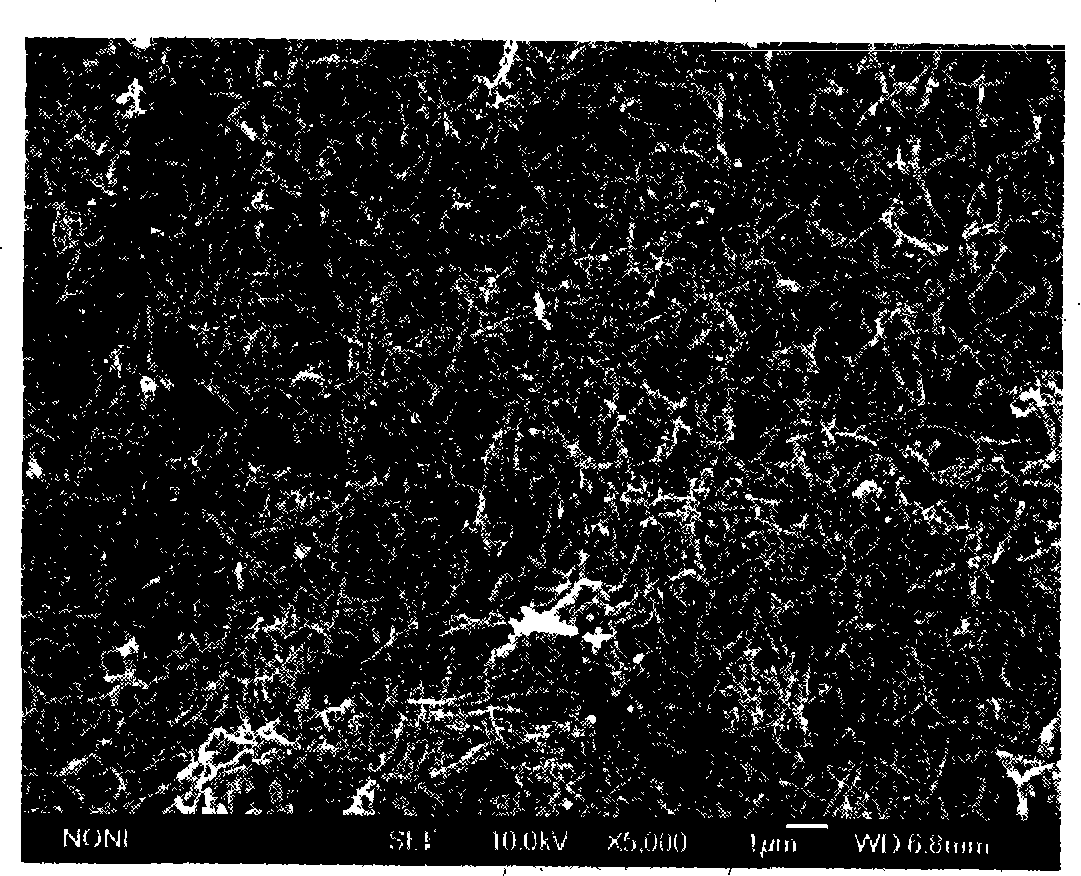

[0015] 1.415 g of polysulfone was dissolved in 6 mL of N,N-dimethylacetamide to obtain a N,N-dimethylacetamide solution containing 20% polysulfone. Then coat a film on the surface of the stainless steel electrode to control the thickness of the liquid film to 100 μm. Afterwards, the stainless steel electrode coated with polysulfone N, N-dimethylacetamide solution was quickly immersed in a coagulation bath (water) to complete phase inversion, and a polysulfone / stainless steel composite electrode was obtained. The polysulfone / stainless steel composite electrode was used as the working electrode, and another piece of stainless steel was used as the counter electrode. -1 Aniline and 1.00mol·L -1 Sulfuric acid was used as the electrolyte, and a cell voltage of 1.80V was used for electrolytic polymerization for 40 minutes to obtain polyaniline nanowires, the purity of which was 100%.

Embodiment 3

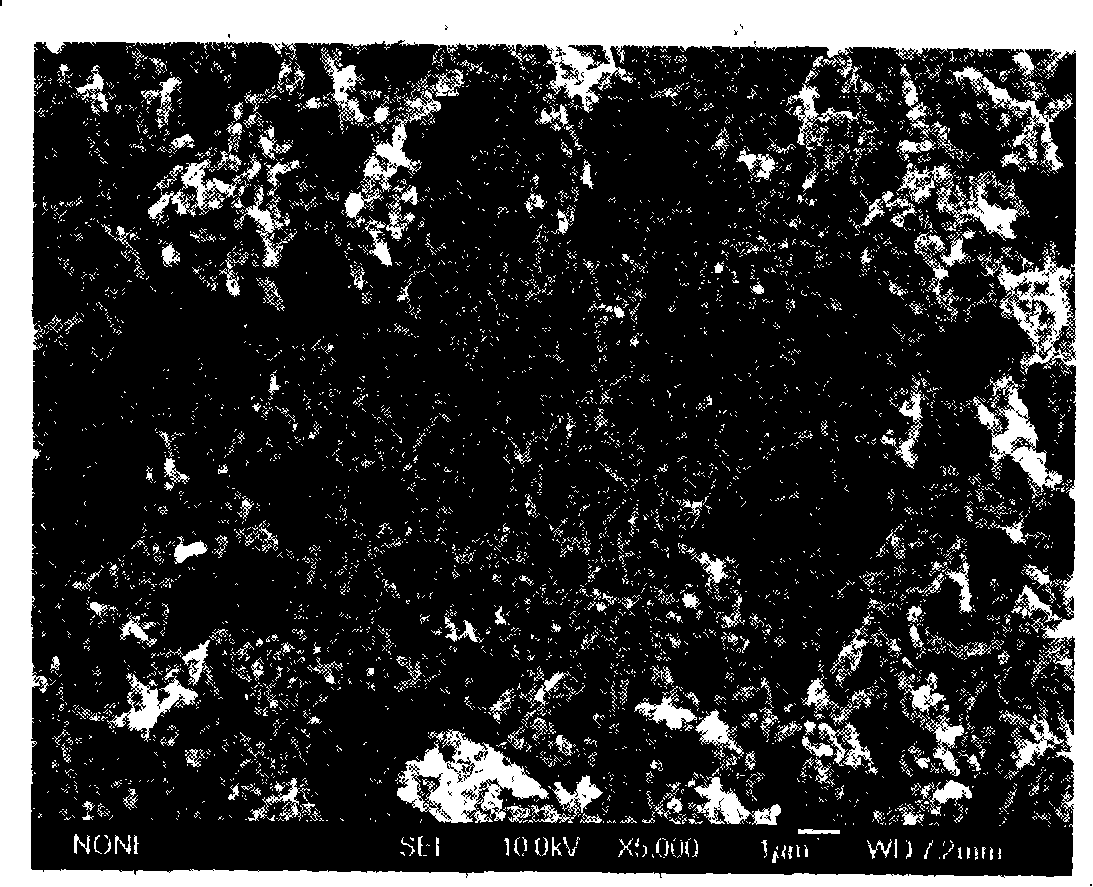

[0017] 2.425 g of polysulfone was dissolved in 6 mL of N,N-dimethylacetamide to obtain a N,N-dimethylacetamide solution containing 30% polysulfone. Then coat a film on the surface of the stainless steel electrode to control the thickness of the liquid film to 150 μm. Afterwards, the stainless steel electrode coated with polysulfone N, N-dimethylacetamide solution was quickly immersed in a coagulation bath (water) to complete phase inversion, and a polysulfone / stainless steel composite electrode was obtained. The polysulfone / stainless steel composite electrode was used as the working electrode, and another piece of stainless steel was used as the counter electrode. -1 Aniline and 1.00mol·L -1 Sulfuric acid was used as the electrolyte, and a cell voltage of 1.80V was used for electrolytic polymerization for 40 minutes to obtain polyaniline nanowires, the purity of which was 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com