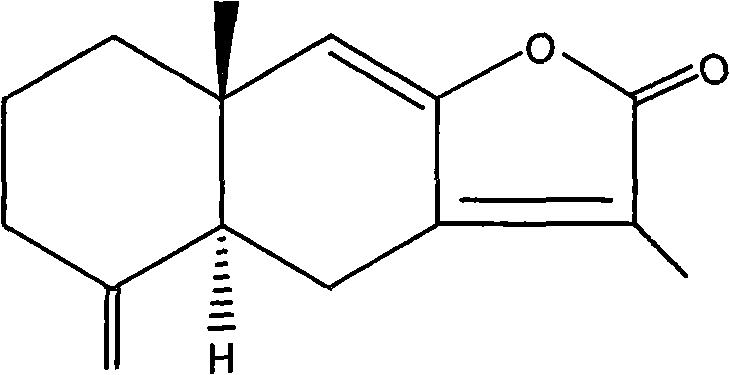

Method for separating effective constituent butenolide II from astraolylis lancea formalyrata volatile oil

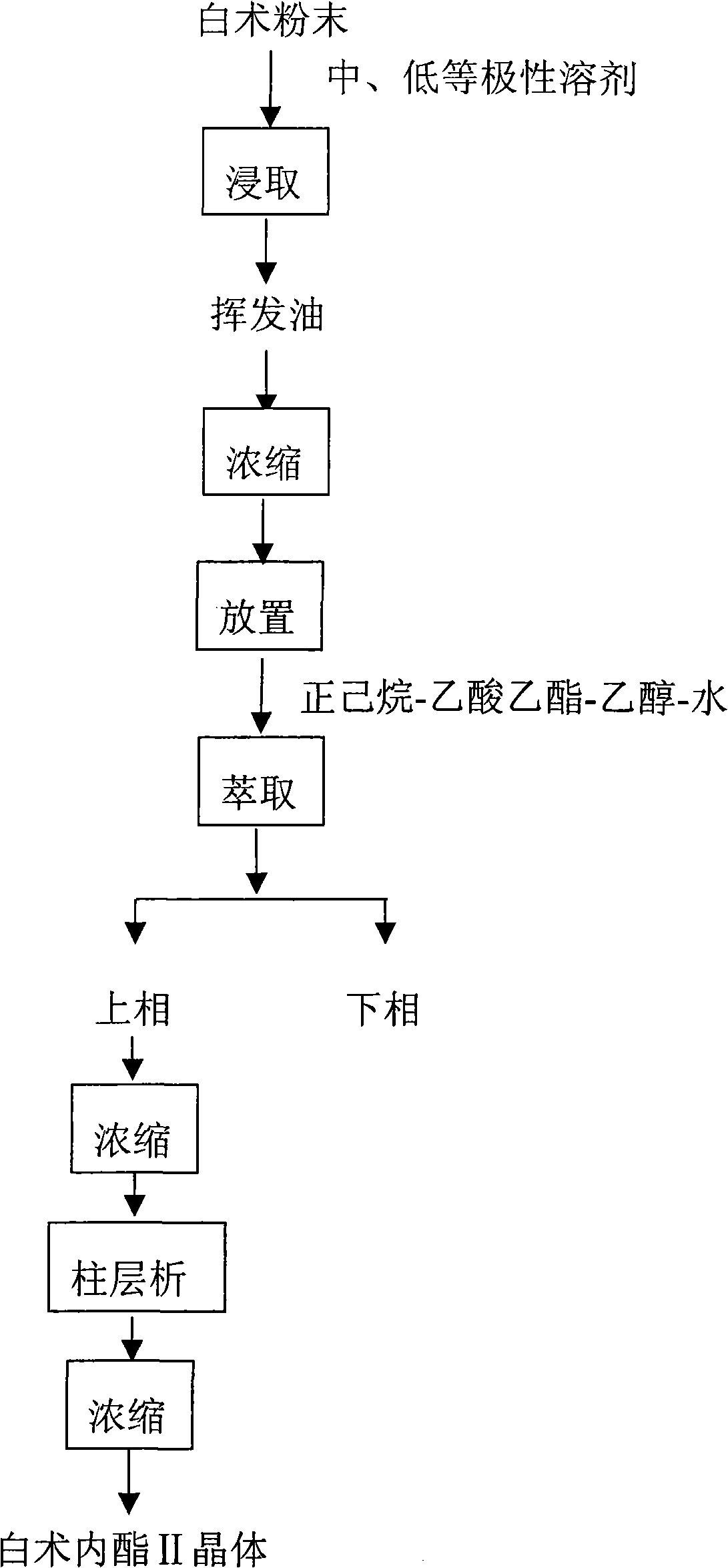

A technique for volatile oil of Atractylodes Rhizoma and Atractylodes Rhizoma Lactone is applied in the field of traditional Chinese medicine, and can solve the problems of material yield, low purity, difficult separation, loss of material and the like, and achieve the effects of improving yield and purity, simple operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

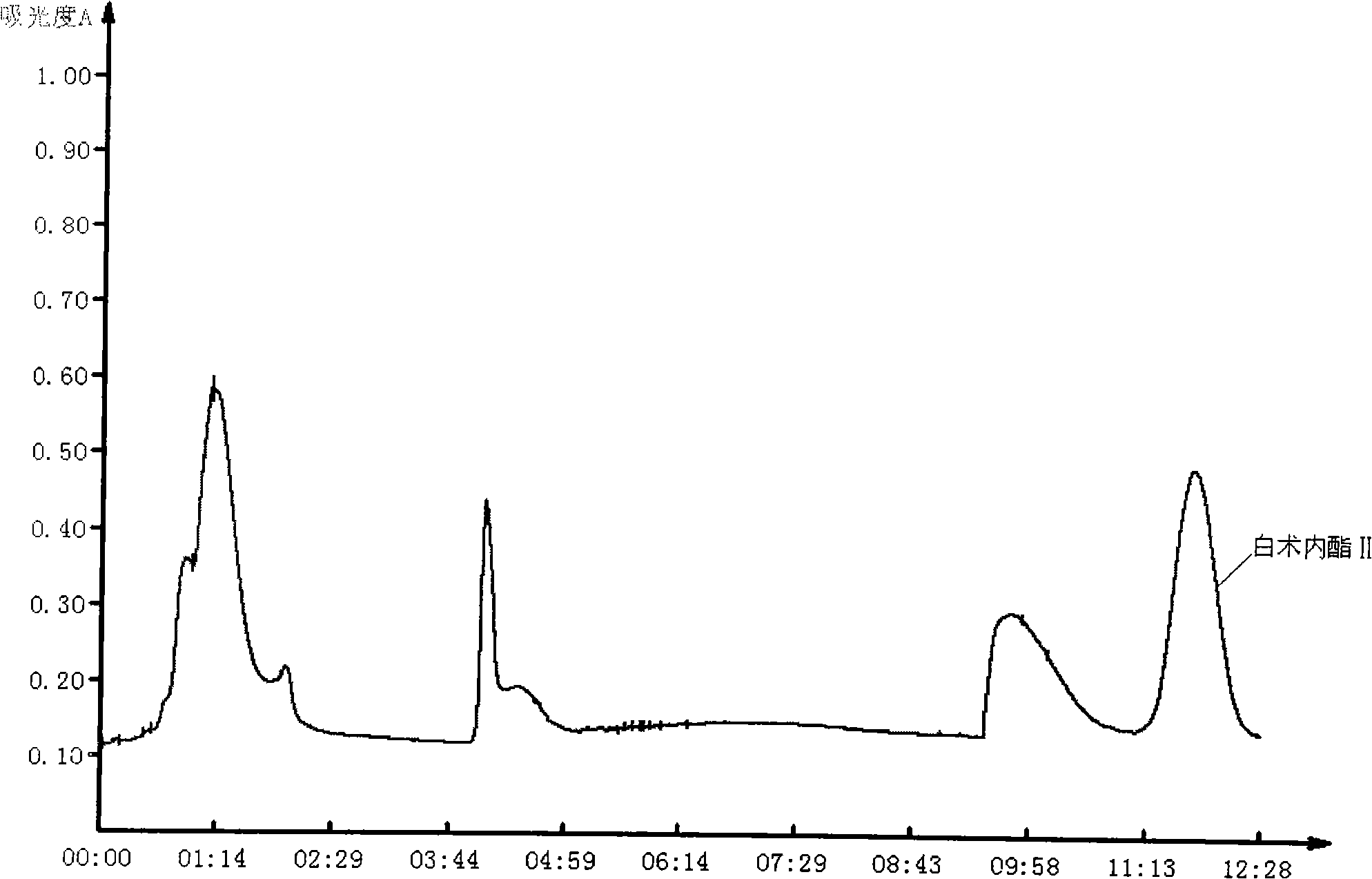

[0026] Dry the rhizome of Atractylodes macrocephala naturally, crush it into coarse powder of Atractylodes macrocephala, soak it twice with 5 times the volume of ethyl acetate (in a constant temperature water bath at 60°C, stirring at a speed of 500r / min, for 1 hour each time), and concentrate to obtain a yellow-brown volatile oil. After standing for a period of time to make it fully oxidized, extract with a mixed solution of n-hexane-ethyl acetate-ethanol-water in the ratio of 4:1:4:1, take the upper phase and concentrate to obtain a refined volatile oil. The refined volatile oil is separated with 60-100 mesh silica gel in a Φ1.0×40cm chromatographic column, and firstly removed with petroleum ether-ethyl acetate mixed solvent at an elution gradient of 300:1 and a flow rate of 5ml / min Impurity peaks, and then elute with a mixed solvent of petroleum ether-ethyl acetate at an elution gradient of 50:1 and a flow rate of 1ml / min, collect the corresponding fractions, concentrate, an...

Embodiment 2

[0028] Naturally dry the Rhizome of Atractylodes Rhizome, crush it into coarse powder of Atractylodes Rhizoma Atractylodes Rhizoma Atractylodes Rhizoma Atractylodes Rhizome, and leaching twice with a mixed solvent made of 5 times the volume of petroleum ether-ethyl acetate in a ratio of 1:1 (60°C constant temperature water bath, stirring speed 500r / min, 1h each time), after standing for a period of time to make it completely oxidized, extract with a mixed solution prepared in the ratio of n-hexane-ethyl acetate-ethanol-water in the ratio of 4:1:4:1, take the upper phase and concentrate to obtain Refined volatile oil. The refined volatile oil is separated with 60-100 mesh silica gel in a Φ1.0×40cm chromatographic column, and firstly removed with petroleum ether-ethyl acetate mixed solvent at an elution gradient of 300:1 and a flow rate of 5ml / min Impurity peaks, and then elute with a mixed solvent of petroleum ether-ethyl acetate at an elution gradient of 50:1 and a flow rate ...

Embodiment 3

[0030] Dry the rhizome of Atractylodes Rhizome naturally, crush it into coarse powder of Atractylodes Rhizoma Atractylodes Rhizoma Atractylodes Rhizoma Atractylodes Rhizome, soak twice with a mixed solvent made of 5 times the volume of petroleum ether-ethyl acetate at a ratio of 40:1 (60°C constant temperature water bath, stirring speed 500r / min, 1h each time), after standing for a period of time to make it completely oxidized, extract with a mixed solution prepared in the ratio of n-hexane-ethyl acetate-ethanol-water in the ratio of 4:1:4:1, take the upper phase and concentrate to obtain Refined volatile oil. The refined volatile oil is separated with 60-100 mesh silica gel in a Φ1.0×40cm chromatographic column, and firstly removed with petroleum ether-ethyl acetate mixed solvent at an elution gradient of 300:1 and a flow rate of 5ml / min Impurity peaks, and then elute with a mixed solvent of petroleum ether-ethyl acetate at an elution gradient of 50:1 and a flow rate of 1ml / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com