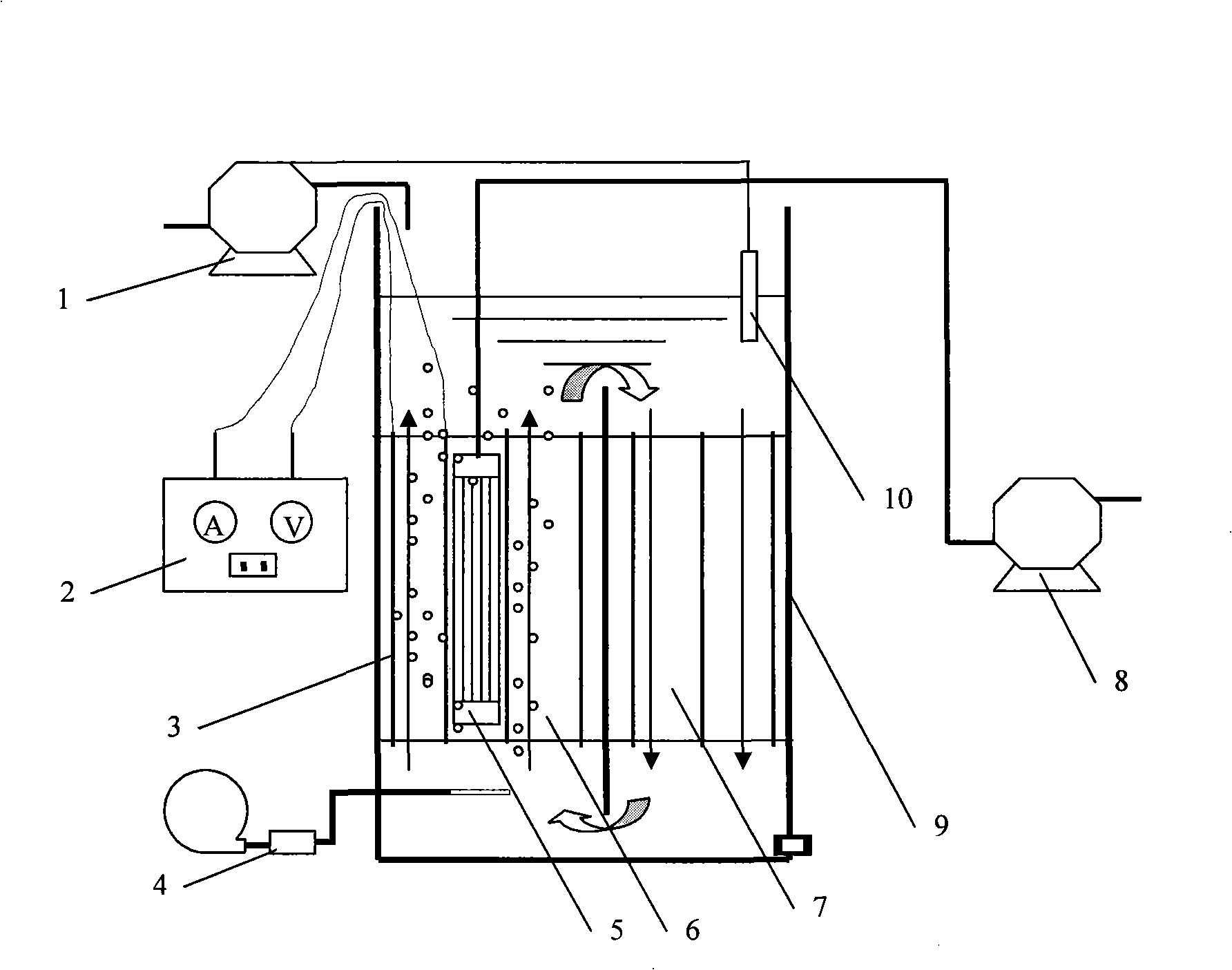

Apparatus and method for removing phosphor and organic matter in sewage water with electric flocculation membrane bioreactor

A membrane bioreactor, electro-flocculation technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sewage treatment, etc., can solve the problems of low phosphorus removal efficiency, increase sludge activity, reduce sludge viscosity, etc. , to reduce costs, delay the occurrence of membrane fouling, and achieve the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Under the condition that the sludge concentration in the membrane bioreactor tank is about 6g / L, and the hydraulic retention time is 11h, three sets of electrode plates are arranged in parallel, the distance between the electrode plates is 3.0cm, and the anode is made of iron plate. DC voltage, current density is 40A / m 2 , when the total phosphorus content in the influent is 5.0mg / L, the COD concentration is 300mg / L, and the ammonia nitrogen is 50mg / L, the removal rates of COD and ammonia nitrogen in the effluent of the membrane bioreactor are above 90% and 95% respectively. After 24 hours of electrolysis, the electrode plate is powered off, and the total phosphorus content of the effluent can be kept below 0.5mg / L for 5 days, and the flocs produced are discharged together with the sludge from the membrane bioreactor.

Embodiment 2

[0031] Example 2: Under the condition that the sludge concentration in the membrane bioreactor tank is about 6g / L and the hydraulic retention time is 11h, a group of electrode plates are arranged in parallel, the distance between the electrode plates is 2.0cm, and the anode is made of iron plate. DC voltage, current density is 20A / m 2 , when the total phosphorus content in the influent is 5.0mg / L, the COD concentration is 300mg / L, and the ammonia nitrogen is 50mg / L, the removal rates of COD and ammonia nitrogen in the effluent of the membrane bioreactor are above 90% and 95% respectively. After 48 hours of electrolysis, the electrode plate is powered off, and the total phosphorus content of the effluent can be kept below 0.5mg / L for 3 days, and the flocs produced are discharged together with the sludge from the membrane bioreactor.

Embodiment 3

[0032] Embodiment 3: Membrane flux is 9L / (m in membrane bioreactor 2 .h), the sludge concentration in the reactor is about 6g / L, and the hydraulic retention time is 11h. Two sets of electrode plates are arranged in parallel. The distance between the electrode plates is 1.0cm. The anode is made of aluminum plate. The density is 80A / m 2 , when the total phosphorus content in the influent is 5.0mg / L, the COD concentration is 300mg / L, and the ammonia nitrogen is 50mg / L, the removal rates of COD and ammonia nitrogen in the effluent of the membrane bioreactor are above 90% and 95% respectively. After 24 hours of electrolysis, the electrode plate is powered off, and the total phosphorus content of the effluent can be kept below 0.5mg / L for 7 days, and the flocs produced are discharged together with the sludge from the membrane bioreactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com