Method for extracting corosolic acid from plant

A technology of corosolic acid and plants, which is applied in the field of green chemical production, can solve the problems of high viscosity and water-soluble impurities, low purity of corosolic acid, and high total production cost, so as to reduce viscosity and water-soluble impurities, Increased saturated adsorption capacity and selectivity, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

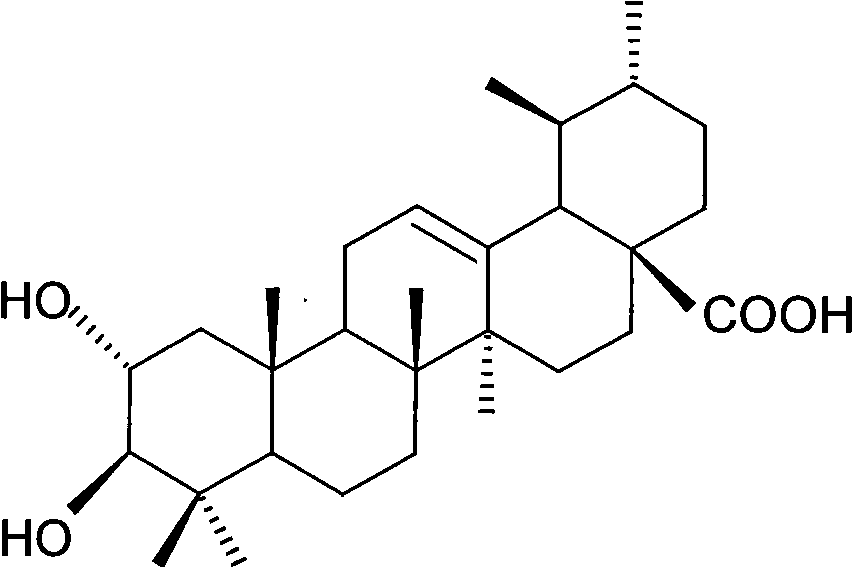

Image

Examples

Embodiment 1

[0028]Wash fresh loquat leaves with water, dry (air-dried, oven-dried or sun-dried), pulverize, and sieve through 20-30 meshes to obtain powder, put 4.9kg of loquat leaf powder into an extraction tank, and use 10 times the dry weight of loquat leaves Boil pure water for 2 times, 1 hour each time, combine the extracts, filter, and concentrate the filtrate into an extract in a vacuum; add 30% ethanol aqueous solution of 10 times the dry weight of loquat leaves to the filter residue, and add 1.0% NaOH of the solution weight to adjust the pH of the solution Value, extract at 48°C for 3 hours, filter, adjust the pH value of the filtrate to 7.5, let it stand for aging, separate the solid and liquid, the precipitate is the crude product of total triterpene acids, and the extraction rate of corosolic acid can reach 96.3% ; Under the condition of 65°C, fully dissolve the crude product of total triterpene acids with 3 times of weight of 95% ethanol solution, remove the insoluble matter t...

Embodiment 2

[0030] Put 5.3kg of Lagerstroemia indica leaf powder into an extraction tank, add tap water 5 times the dry weight of Lagerstroemia indica leaves, boil for 2 times, 1 hour each time, combine the extracts, filter, and concentrate the filtrate into an extract by vacuum; add the filter residue 10 times the dry weight of crape myrtle leaves in 60% methanol aqueous solution, add 0.5% KOH of the solution weight to adjust the pH value of the solution, extract 3 times at 30°C, each time for 1 hour, combine the extracts, filter, and adjust the pH of the filtrate When the value reaches 4.5, let it stand for aging, separate solid and liquid, and the precipitate is the crude product of total triterpene acid, wherein the extraction rate of corosolic acid can reach 91.9%; Dissolve the crude product of total triterpene acid, remove the insoluble matter by solid-liquid separation, adjust the final concentration of corosolic acid in the filtrate system to 2.5g / L, the final concentration of meth...

Embodiment 3

[0032] Put 6.1kg of C. chinensis powder into the extraction tank, add tap water with 8 times the dry weight of C. chinensis, boil for 2 times, 1 hour each time, combine the extracts, filter, and concentrate the filtrate into an extract by vacuum; add 5 times the dried C. Heavy 35% methanol aqueous solution, add 0.8% NaOH of the solution weight to adjust the pH value of the solution, extract twice at 50°C for 2 hours each time, combine the extracts, filter, adjust the pH value of the filtrate to 6.5 and let it stand for aging , solid-liquid separation, and the precipitate is the crude product of total triterpene acids, wherein the extraction rate of corosolic acid can reach 95.1%; at 50°C, fully dissolve the crude product of total triterpene acids with 90% methanol of 8 times the weight, Solid-liquid separation to remove insoluble matter, adjust the final concentration of corosolic acid in the filtrate system to 1.6g / L, the final concentration of methanol to 38%, and the final c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com