Iota-carrageenan even oligosacchride alcohol monomer and preparation thereof

An even-numbered oligosaccharide, iota-technology, applied in the field of iota-carrageenan even-numbered oligosaccharide alcohol monomer and its preparation, to achieve the effects of no three-waste pollution, stable product performance, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

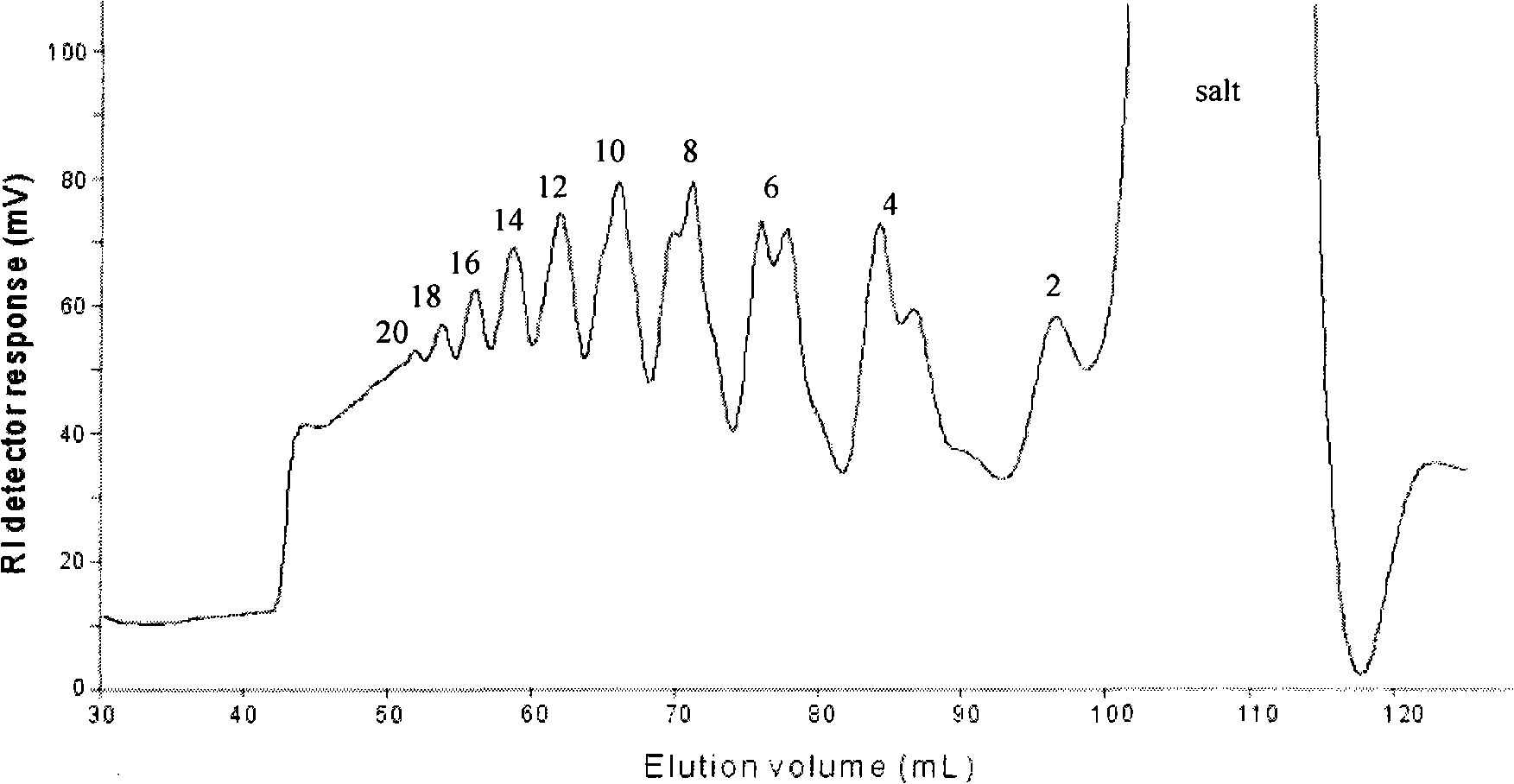

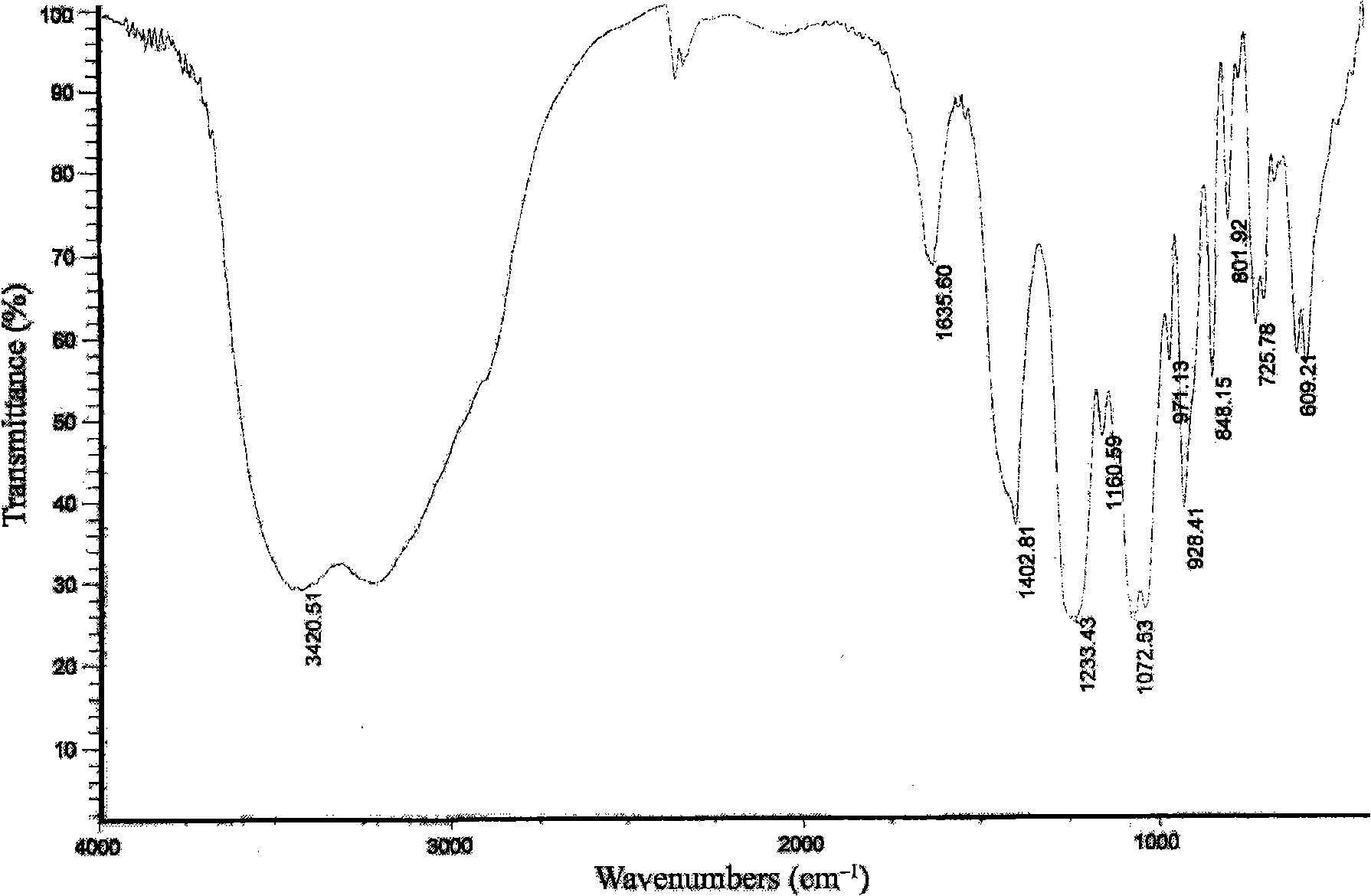

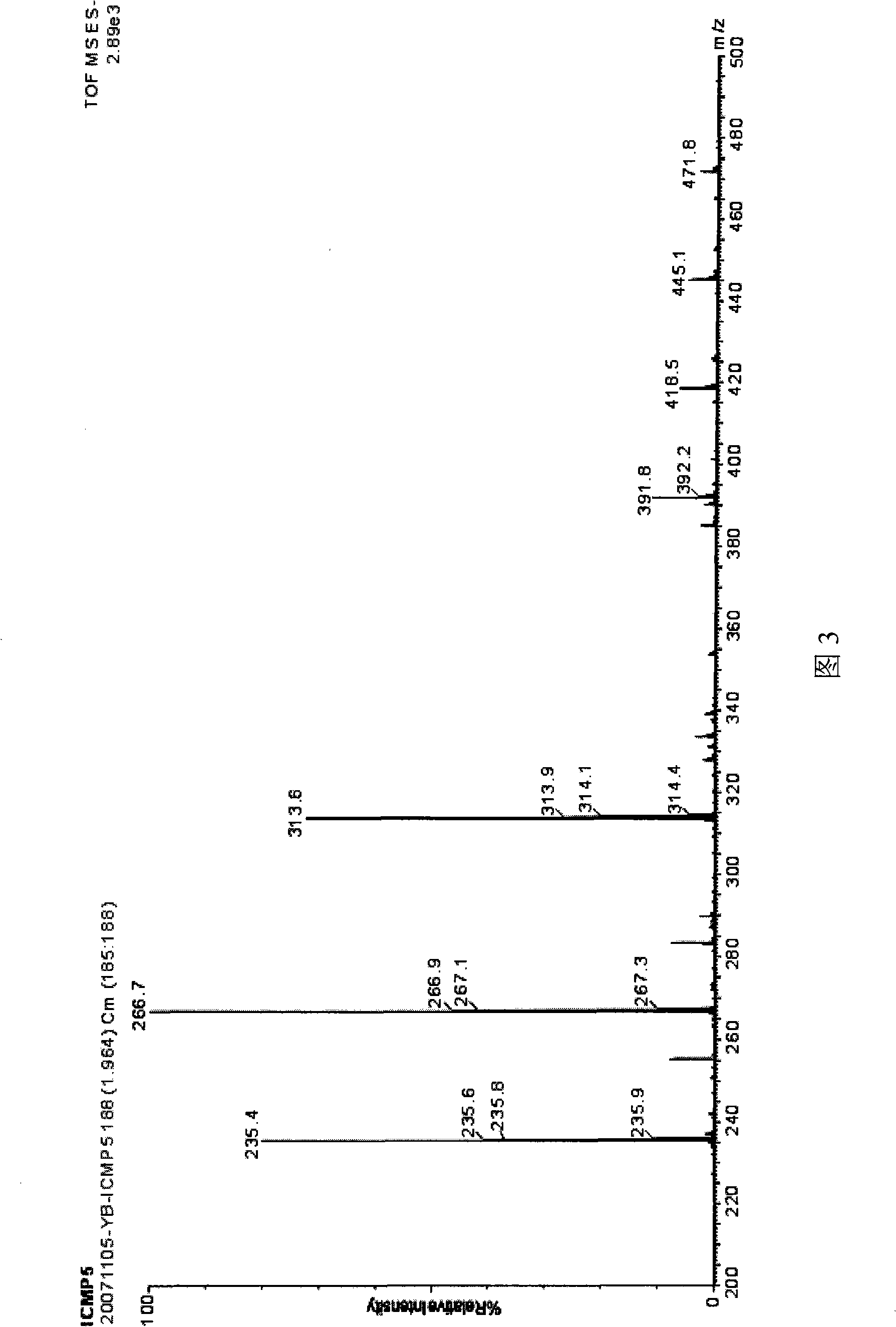

[0014] Dissolve iota-carrageenan into a 1-5% (W / W) aqueous solution with hydrochloric acid with a concentration of 0.1-0.5mol / L, then add sodium borohydride, the concentration of sodium borohydride in the aqueous solution is 0.2-2.0mol / L, the iota-carrageenan in the aqueous solution was degraded at 50-95°C for 30-480 minutes under stirring, and filtered, and the filtrate was neutralized with aqueous sodium hydroxide solution, concentrated by rotary evaporation, and precipitated with absolute ethanol. Wash and dissolve the precipitate in water, then use 0.2mol / L ammonium bicarbonate aqueous solution as the mobile phase, use Superdex 30 packing for column chromatography, detect with differential detector, collect according to the elution peaks, concentrate, and freeze-dry to obtain The iota-carrageenan even-numbered oligosaccharide alcohol monomer of the present invention.

[0015] The hydrochloric acid described in the present embodiment can use sulfuric acid, nitric acid, for...

Embodiment 2

[0017] Dissolve iota-carrageenan in water into a 0.5-5% (W / W) aqueous solution, add 2-20 grams of hydrogen-type cation exchange resin, and then add 4-methylmorpholine borane to make 4-methylmorpholine borane The concentration of alkane is 0.2-2.0mol / L. The above aqueous solution is degraded under stirring at 50-95°C for 30-480 minutes and then filtered. The filtrate is neutralized with ammonium hydroxide. After filtration, it is concentrated by rotary evaporation and precipitated with acetone. , washing, then use 0.2mol / L ammonium bicarbonate aqueous solution as mobile phase, carry out column chromatography separation with BioGel P10 filler, detect with differential detector, merge and collect by elution peak, concentrate, freeze-dry to obtain final product of the present invention iota-carrageenan even-numbered oligosaccharide alcohol monomer.

[0018] The hydrogen type cation exchange resin described in the present embodiment is 732 resins, Dowex AG50W X4 resin or Amberlite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com