Polymer loaded with ion liquid, preparation and application thereof

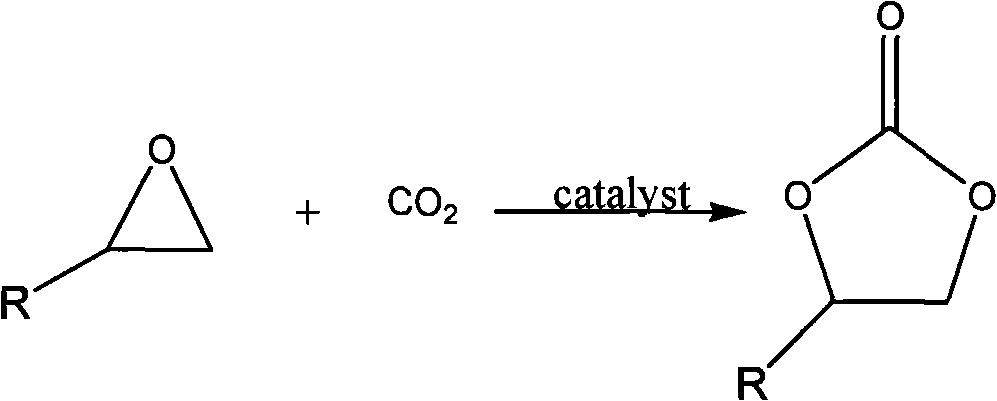

A technology of ionic liquids and polymers, which is applied in the field of cyclic carbonates, can solve the problems of inconvenient recovery of ionic liquids and difficulties in the reuse of catalysts, and achieve the effects of firm loading, simple preparation process, and simple treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1, preparation is loaded with the polymer of ionic liquid

[0015] 5.5 g of 1-vinylimidazole and 18.5 g of chlorobutane were stirred and refluxed at 70°C under a nitrogen atmosphere for 24 hours, cooled to room temperature, and the lower precipitate was washed with ethyl acetate to obtain 4.46 g of chlorovinylbutyl imidazole. Under the protection of nitrogen, 1.0 g of divinylbenzene, 0.5 g of chlorovinylbutylimidazole and 0.05 g of AIBN were dissolved in 250 ml of chloroform, stirred and refluxed at 70 ° C for 48 hours, and the obtained solid was filtered and washed with tetrahydrofuran and methanol respectively. Wash with acetone and dry under vacuum at 50° C. to obtain a polymer loaded with ionic liquid.

[0016] The polymer was ground into powder in a glass mortar, elemental analysis: N: 5.24; C: 74.69; H: 7.86; Cl: 7.82.

Embodiment 2

[0018] Under nitrogen protection, 3.2 grams of divinylbenzene, 0.5 grams of chlorovinylbutylimidazole obtained in Example 1 and 0.05 grams of AIBN were dissolved in 250 milliliters of chloroform, stirred and refluxed at 70 ° C for 48 hours, and the obtained solid was filtered. Wash with tetrahydrofuran, methanol and acetone respectively, and dry under vacuum at 50°C to obtain a polymer loaded with ionic liquid.

[0019] The polymer was ground into powder in a glass mortar, elemental analysis: N: 2.18; C: 82.73; H: 7.81; Cl: 3.55.

Embodiment 3

[0021] Under nitrogen protection, 3.0 grams of divinylbenzene, 0.15 grams of chlorovinylbutylimidazole obtained in Example 1 and 0.05 grams of AIBN were dissolved in 250 milliliters of chloroform, stirred and refluxed at 70 ° C for 48 hours, and the obtained solid was filtered. Wash with tetrahydrofuran, methanol and acetone respectively, and dry under vacuum at 50°C to obtain a polymer loaded with ionic liquid.

[0022] The polymer was ground into powder in a glass mortar, elemental analysis: N: 1.00; C: 88.36; H: 7.83; Cl: 1.46.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com