Lithium ionic cell cathode material of graphite-like structure and preparing process thereof

A lithium-ion battery and graphite structure technology, applied in battery electrodes, structural parts, chemical instruments and methods, etc., can solve the problems of cumbersome steps, high cost, and difficulty in industrialization, and achieve simple preparation methods and prevent dendrites The effect of generating and solving security problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the lithium-ion battery negative electrode material of graphite-like structure of the present invention comprises the following steps:

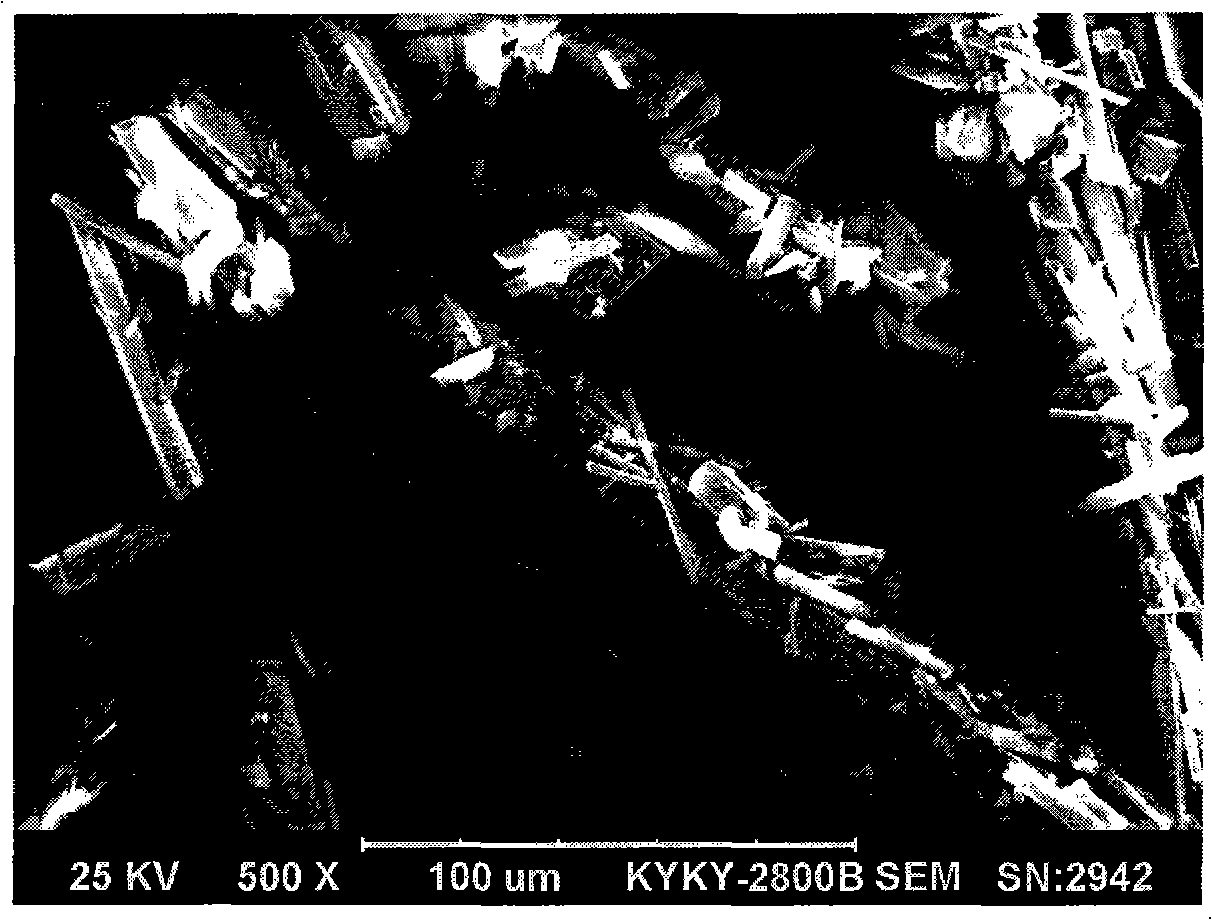

[0024] 1. Weigh the nitrogen-containing compound and boric acid respectively according to the amount ratio of substances 6-1:1-6, and the nitrogen-containing compound is any one of pyrrole, amine, oxazine, pyridine, urea and amino acid nitrogen-containing compound A mixture of two or more substances, respectively dissolve 1-6mol of nitrogen-containing compound in water at 25-100°C, dissolve 6-1mol of boric acid in water at 25-100°C, and then slowly inject boric acid into the dissolved nitrogen-containing compound solution , stirred for 0.1-10 h, cooled naturally to room temperature to obtain needle-shaped precursors, and detected with a scanning electron microscope, using a KYKY-2800B scanning electron microscope from Beijing Zhongke Keyi Technology Development Co., Ltd.

[0025] 2. Put the needle-shaped precu...

Embodiment 1

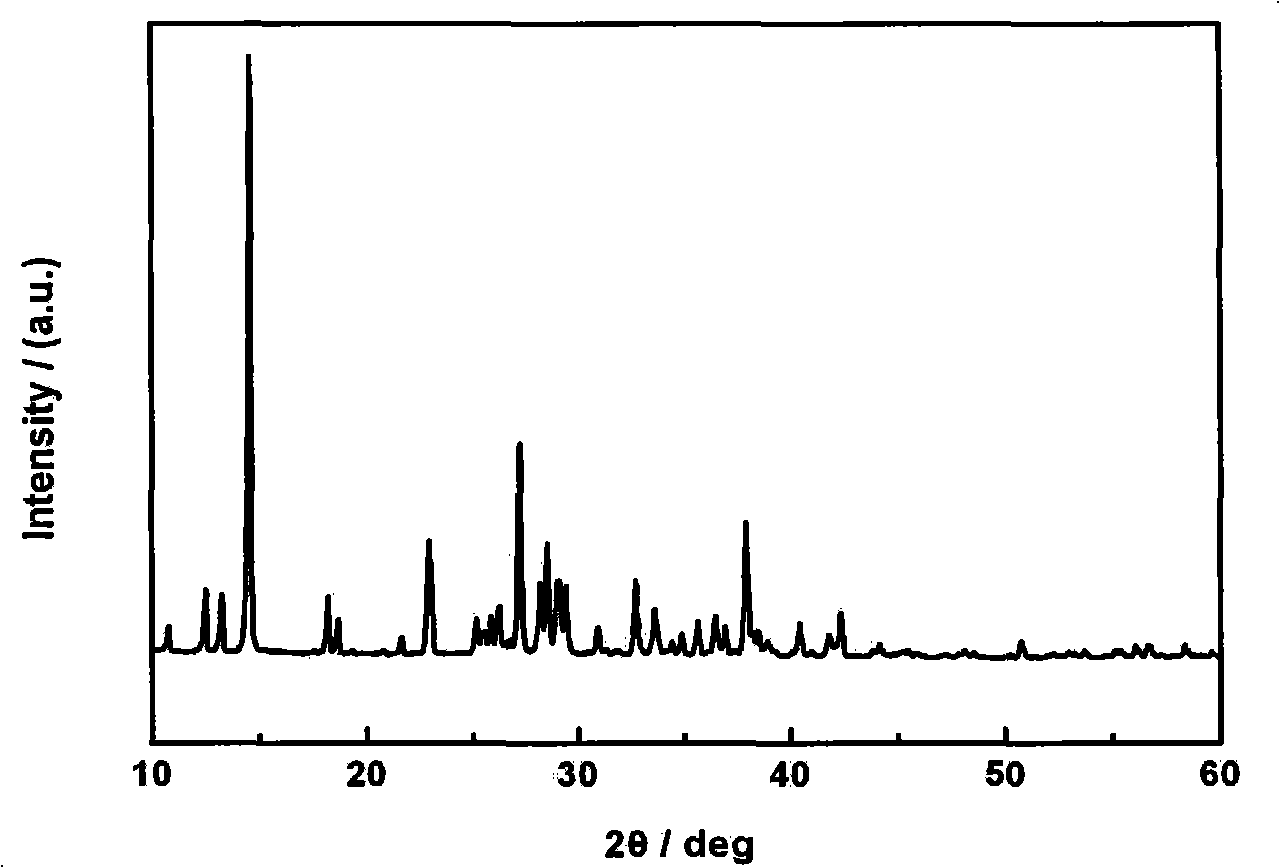

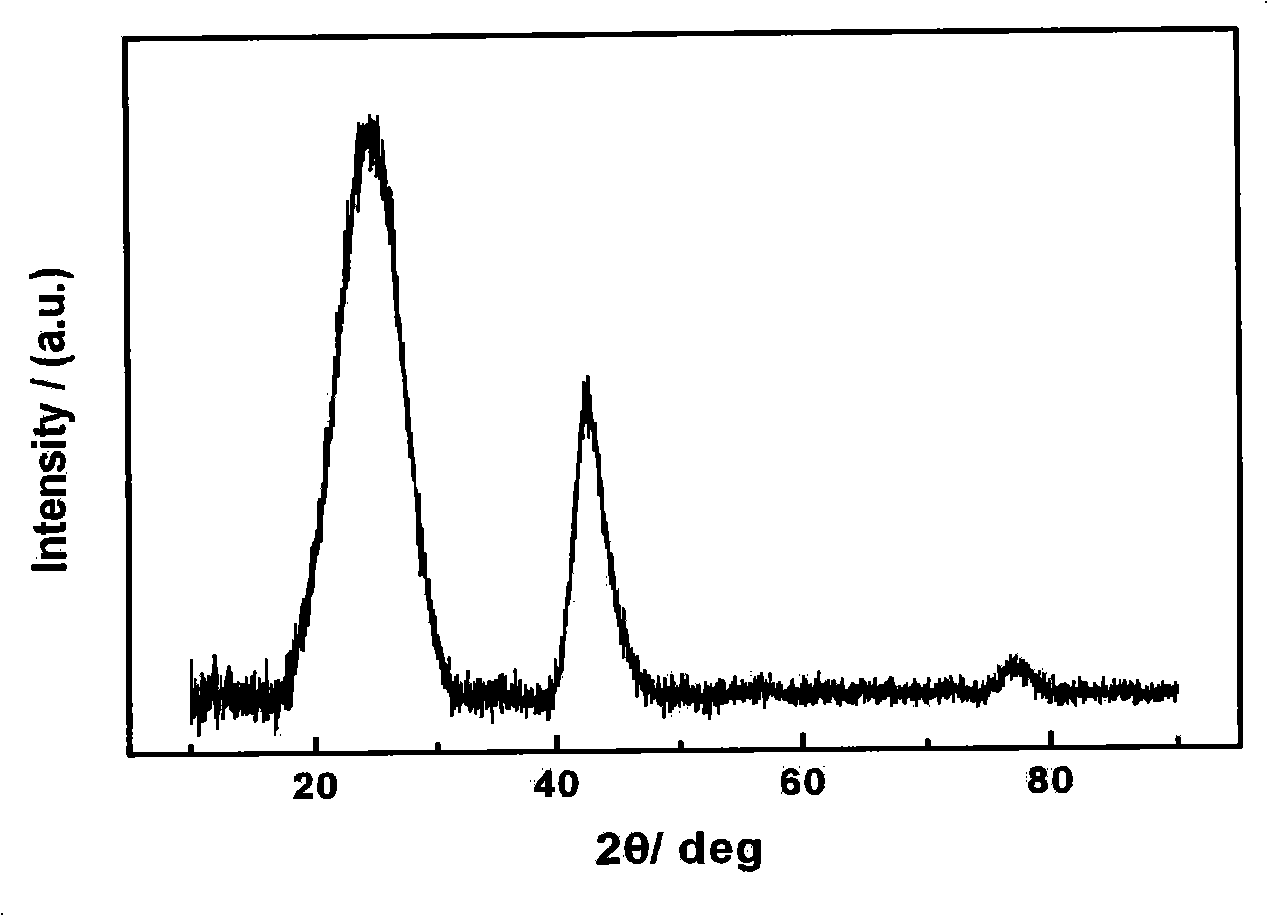

[0030] Example 1, according to the nitrogen-containing compound melamine: the boric acid substance ratio is 1: 3 and weighs 1 mol and 3 mol of the two compounds, respectively, the nitrogen-containing compound is dissolved in 250 ml of water at 30 ° C, and the boric acid is dissolved in 125 ml of 50 ° C water, and then slowly inject the boric acid solution into the dissolved nitrogen-containing compound solution, continue to stir for 0.5h, and naturally cool to room temperature to prepare the needle-like precursor, such as figure 1 As shown, the particles are fibrous, 20-200 μm long and 1-20 μm wide. Such as figure 2 As shown, the precursor is composed of compounds containing B, C, and N elements. The above-mentioned needle-shaped precursor and lithium hydroxide are mixed uniformly by ball milling with a ratio of 1 mol and 2 mol according to the amount of substances, and the temperature is raised to 800°C at a heating rate of 5°C / min and kept for 50h, and naturally cooled to ...

Embodiment 2

[0032] In Example 2, 3 mol and 1 mol of the two compounds were weighed according to the nitrogen-containing compound melamine: boric acid substance ratio of 3:1. The nitrogen-containing compound was dissolved in 1000ml at 95°C, and the boric acid was dissolved in 500ml at 80°C, and then the boric acid solution was slowly injected into the dissolved nitrogen-containing compound solution, stirred continuously for 10h, and naturally cooled to room temperature to prepare the needle-shaped precursor. The above-mentioned precursor and lithium hydroxide were mixed evenly by ball milling in a ratio of 1:6, 1mol and 6mol, and the temperature was raised to 1200°C at a heating rate of 10°C / min for 5 hours, and naturally cooled to room temperature. min; then place the obtained material in a heating device, heat it up to 2500°C at a heating rate of 5°C / min and keep it warm for 180 hours, and then carry out graphitization treatment. , to obtain a material with a fibrous crystal structure, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Maximum discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com