Polyaniline nano-fibre and method for preparing same

A nanofiber and polyaniline technology, which is applied in the field of polyaniline nanofibers and its preparation, can solve the problems of difficult removal of template agents, environmental pollution of oil-phase organic solvents, and high production costs, and achieves great practical value and avoids the effects of environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

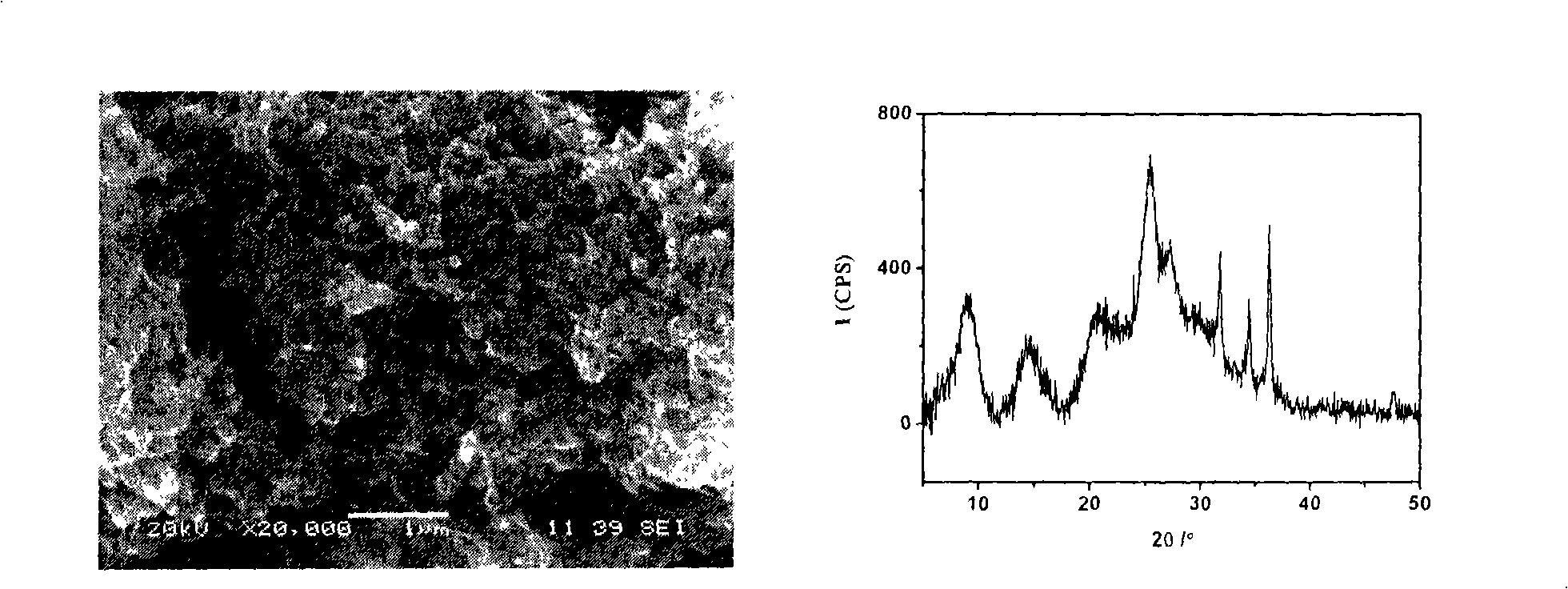

Embodiment 1

[0027] (1) Dissolve 0.5g polyethylene glycol in 30ml water;

[0028] (2) 5ml hydrochloric acid is dissolved in the above-mentioned solution under stirring condition;

[0029] (3) Add 2ml of aniline under stirring condition to form component A;

[0030] (4) 2.0g ammonium persulfate is dissolved in 20ml water to form component B;

[0031] (5) Continuously add component B dropwise to component A under stirring condition at a rate of 0.01ml / min. After the dropwise addition, continue to react for 10 hours, and control the reaction temperature between 3°C;

[0032] (6) After filtering the reaction product, wash with methanol, acetone and deionized water respectively until the filtrate is colorless;

[0033] (7) Carry out secondary doping with hydrochloric acid aqueous solution, the hydrochloric acid concentration that secondary doping is used is 0.5~4.0M, and the time of doping is 10 hours;

[0034] (8) Vacuum drying after washing to obtain polyaniline nanofibers, the vacuum degr...

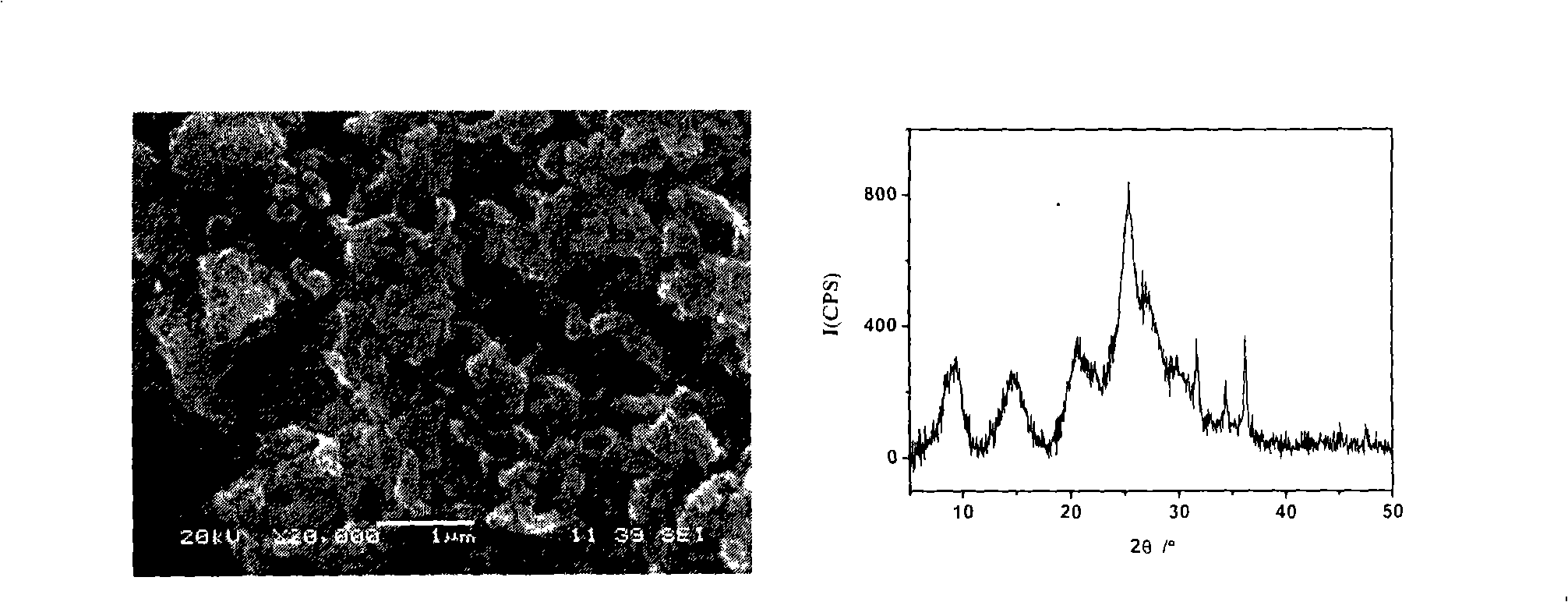

Embodiment 2

[0036] (1) Mix water and water-soluble organic solvent in a volume ratio of 1:1 to form a 100ml homogeneous system;

[0037] (2) 10.0g polyethylene glycol is dissolved in the above system;

[0038] (3) 20ml hydrochloric acid is dissolved in the above-mentioned solution under the condition of stirring;

[0039] (4) Add 10ml of aniline under stirring condition to form component A;

[0040] (5) 20.0g ammonium persulfate is dissolved in the 50ml homogeneous system formed by mixing water and water-soluble organic solvent in a ratio of 1:1 by volume to form component B;

[0041] (6) Continuously add component B dropwise to component A under stirring condition, the dropping rate is 5.0ml / min; after the dropwise addition, continue to react for 24 hours, and the reaction temperature is controlled between 5°C;

[0042] (7) After filtering the reaction product, wash with methanol, acetone and deionized water respectively until the filtrate is colorless;

[0043] (8) carry out secondar...

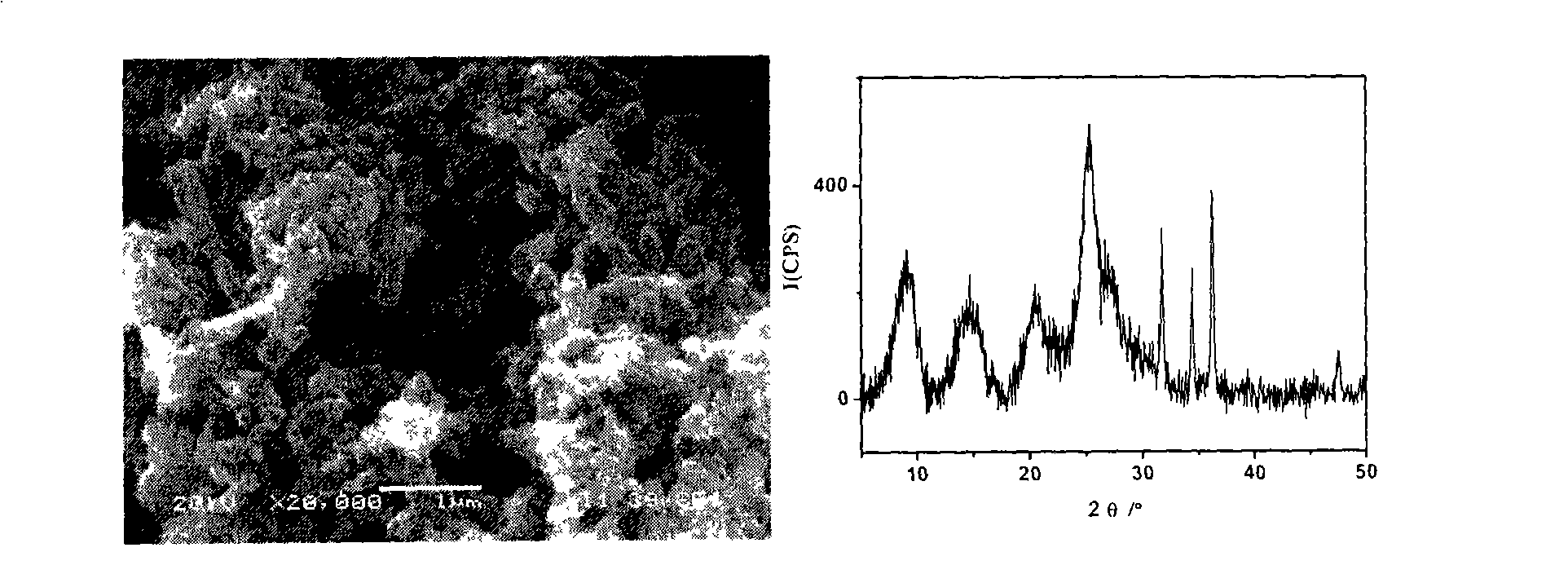

Embodiment 3

[0046] (1) 5.0g polyethylene glycol is dissolved in 60ml water-soluble organic solvent;

[0047] (2) 12ml hydrochloric acid is dissolved in the above-mentioned solution under the condition of stirring;

[0048] (3) Add 5ml of aniline under stirring condition to form component A;

[0049] (4) 10.0g ammonium persulfate is dissolved in 400ml water-soluble organic solvent to form component B;

[0050] (5) Add component B to component A drop by drop continuously under stirring condition, the dropping rate is 0.01-5.0ml / min; after the dropwise addition, continue to react for 1-24 hours, and control the reaction temperature at 0°C ~5°C;

[0051] (6) After filtering the reaction product, wash with methanol, acetone and deionized water respectively until the filtrate is colorless;

[0052] (7) carry out secondary doping with hydrochloric acid aqueous solution, the hydrochloric acid concentration that secondary doping is used is 0.5~4.0M, and the time of doping is 0~48 hours;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com