Preparation method of carbon-silicon compound aerogel

A composite airgel and silica sol technology, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of destroying the pore structure and distribution of airgel, reducing the specific surface area and pore volume, and collapsing the gel network structure. Achieve the effect of preventing network collapse, preventing volume shrinkage, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Mix resorcinol, formaldehyde, and silica sol No. 1 in a molar ratio of 1:2:2, R / C=500, and mix them into an aqueous solution with a solid content of 35g / 100ml, then put it into an ampoule and seal it , aged in a water bath at 85°C for 4 days to obtain a hydrogel.

[0020] (2) Replace the hydrogel with absolute ethanol to make it an organic aerogel, and dry it in a mixed solution of ethanol and petroleum ether at 250° C. and 9 MPa for 4 hours in a supercritical state to obtain a dried organic aerogel.

[0021] (3) The organic airgel was carbonized at 800° C. for 3 h in a carbonization furnace under the protection of nitrogen to obtain a carbon-silicon composite airgel.

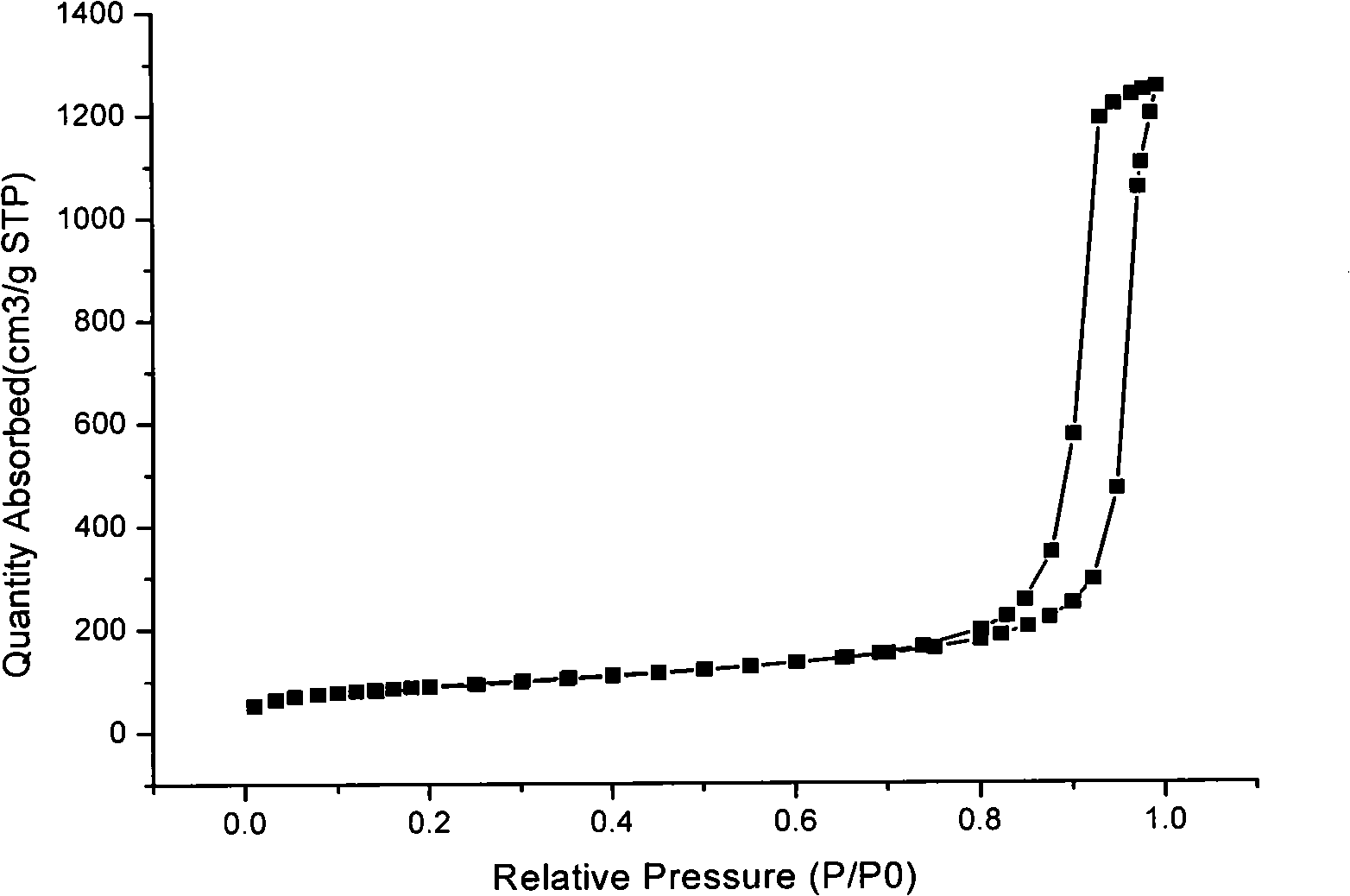

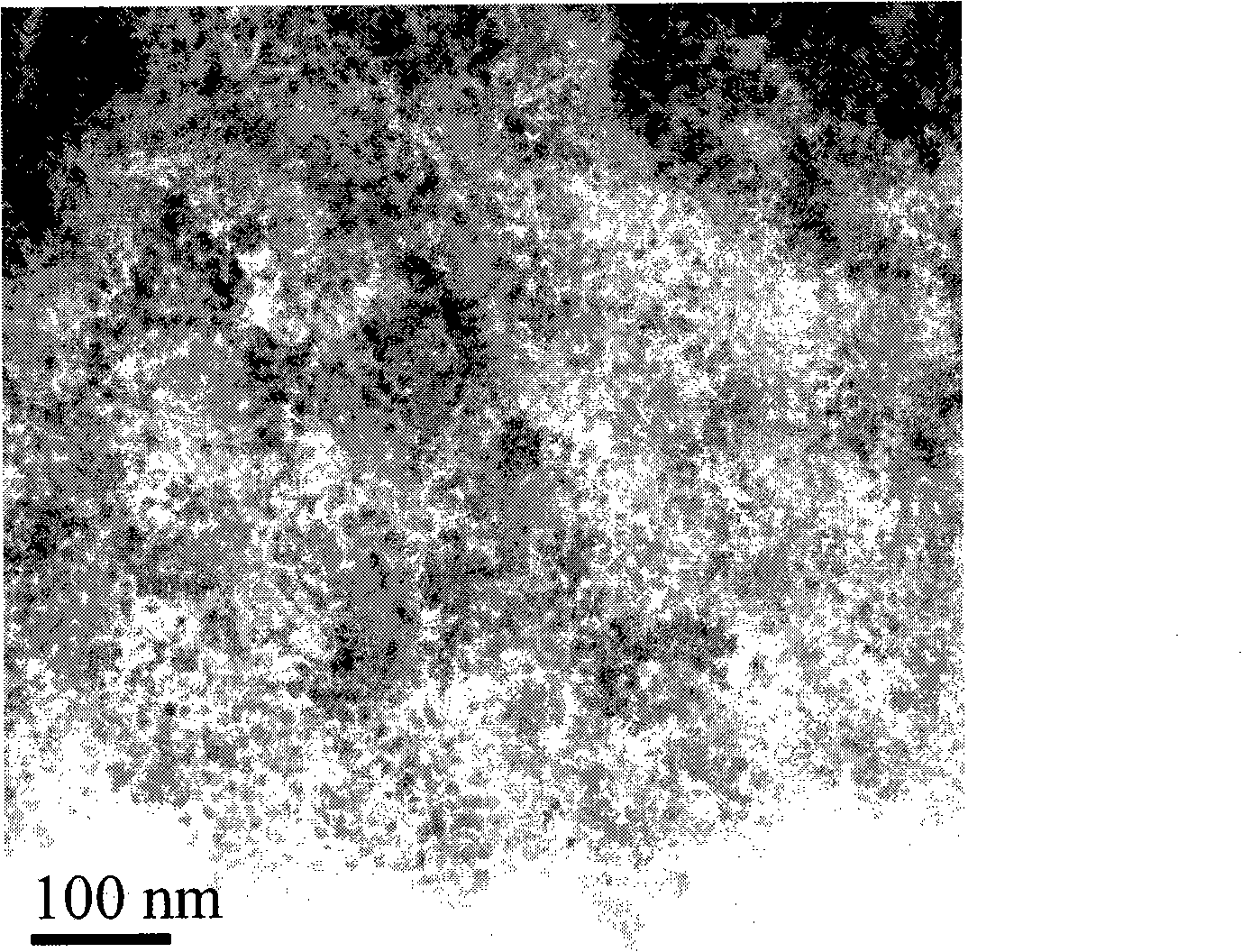

[0022] The true density of the prepared composite gel is 0.55g / m 3 , BET specific surface area is 405m 2 / g, the pore volume is 2.01cm 3 / g.

Embodiment 2

[0024] (1) Mix resorcinol, formaldehyde, and silica sol No. 2 in a molar ratio of 1:2:2, R / C=500, mix and prepare an aqueous solution with a solid content of 35g / 100ml, and then put it into an ampoule and seal it , aged in a water bath at 85°C for 4 days to obtain a hydrogel.

[0025] (2) Replace the hydrogel with absolute ethanol to make it an organic aerogel, and dry it in a mixed solution of ethanol and petroleum ether at 250° C. and 9 MPa for 4 hours in a supercritical state to obtain a dried organic aerogel.

[0026] (3) The organic airgel was carbonized at 800° C. for 3 h in a carbonization furnace under the protection of nitrogen to obtain a carbon-silicon composite airgel.

[0027] The true density of the composite gel is 0.54g / m 3 , BET specific surface area is 420m 2 / g, the pore volume is 1.97cm 3 / g.

Embodiment 3

[0029] (1) Mix resorcinol, formaldehyde, and silica sol No. 1 in a molar ratio of 1:2:3, R / C=500, mix and prepare an aqueous solution with a solid content of 40g / 100ml, and then put it into an ampoule and seal it , aged in a water bath at 85°C for 4 days to obtain a hydrogel.

[0030] (2) Replace the hydrogel with absolute ethanol to make it an organic aerogel, and dry it in a mixed solution of ethanol and petroleum ether at 250° C. and 9 MPa for 4 hours in a supercritical state to obtain a dried organic aerogel.

[0031] (3) The organic airgel was carbonized at 800° C. for 3 h in a carbonization furnace under the protection of nitrogen to obtain a carbon-silicon composite airgel.

[0032] The true density of the composite gel is 0.53g / m 3 , BET specific surface area is 354m 2 / g, the pore volume is 1.92cm 3 / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com