Glycolic acid oxidase preparation, preparation method and applications

A glycolate oxidase, glycolic acid technology, applied in oxidoreductase, chemical industry, sustainable manufacturing/processing and other directions, can solve the problem that glycolate oxidase has not been reported in literature and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 Medicago clover glycolate oxidase

[0032] Weigh 100g of fresh alfalfa, cool to 4°C, add 140ml of pre-cooled potassium phosphate buffer (100mM, pH8.0), add a small amount of quartz sand to aid research, and filter with four layers of gauze. Centrifuge at 8000rpm for 8min, the volume of the supernatant is about 200ml, put it in an ice bath, stir with low-speed magnetic force, slowly add 9.35g of finely ground ammonium sulfate powder, let it stand for 30min, centrifuge at 13000rpm for 8min, take the supernatant, about 170ml, then slowly add 9.52g Grind fine ammonium sulfate powder, let it stand for 30 minutes, centrifuge at 13000rpm for 8 minutes, take the precipitate, add 5g of lactose powder as a freeze-drying protection agent, freeze-dry to make a crude enzyme preparation, the activity is about 297U / g, and store at 4°C.

Embodiment 2

[0033] The preparation of embodiment 2 magnetic nanomaterials

[0034] Weigh 3.6g of 1,6-hexanediamine, 4.0g of anhydrous sodium acetate, FeCl 3 ·6H 2 O 1.0g, put in a conical flask, add 30ml of ethylene glycol, make it miscible under magnetic stirring, form a transparent liquid, transfer it to a high-pressure reaction kettle, and take it out after standing at 200°C for 6 hours, and the bottom of the kettle can be seen There are black precipitates, which are the required magnetic nanoparticles. Wash the obtained magnetic powder particles with hot water and ethanol (3 times), wash away the residual solvent and 1,6-hexamethylenediamine, dry at 50°C, and set aside.

Embodiment 3

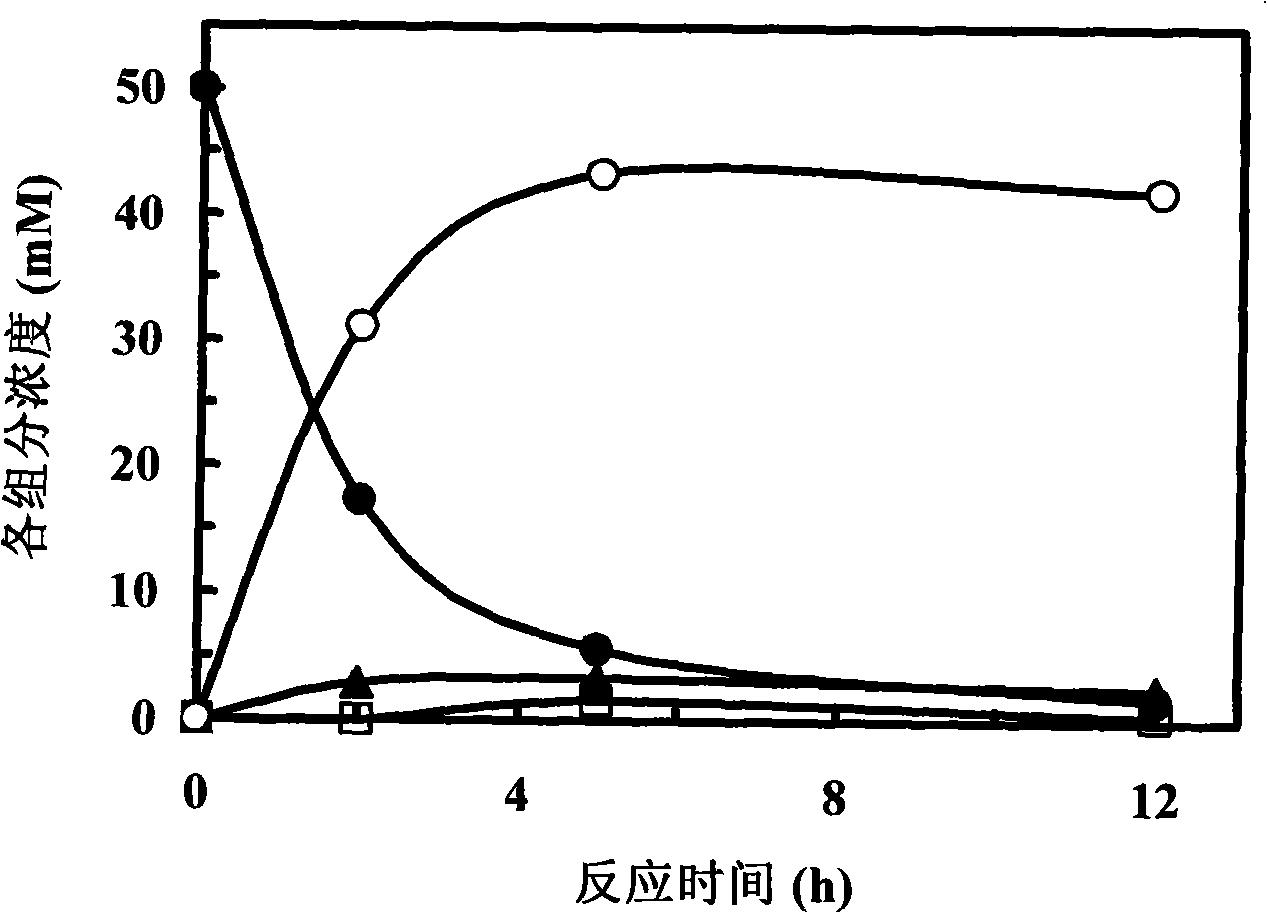

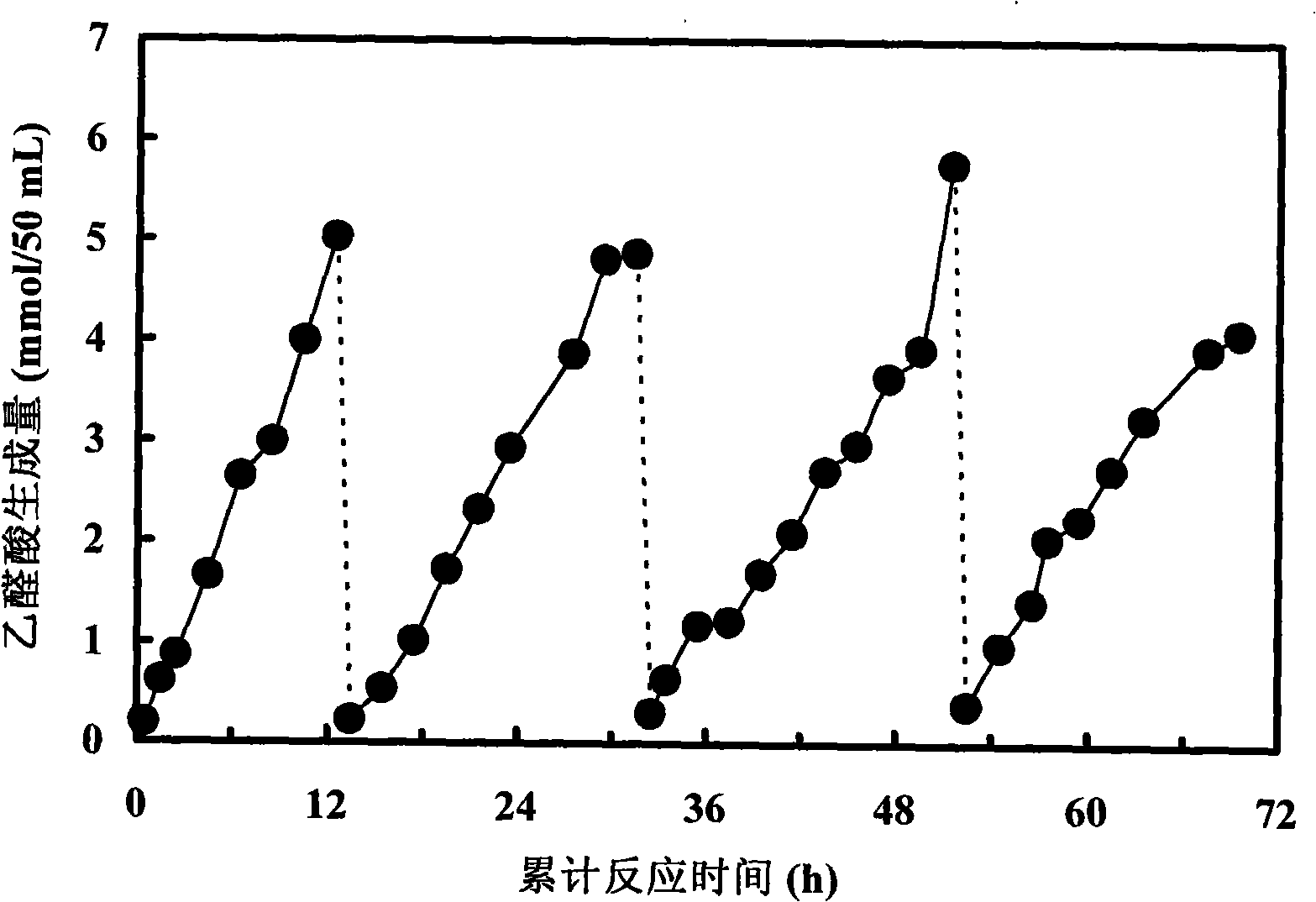

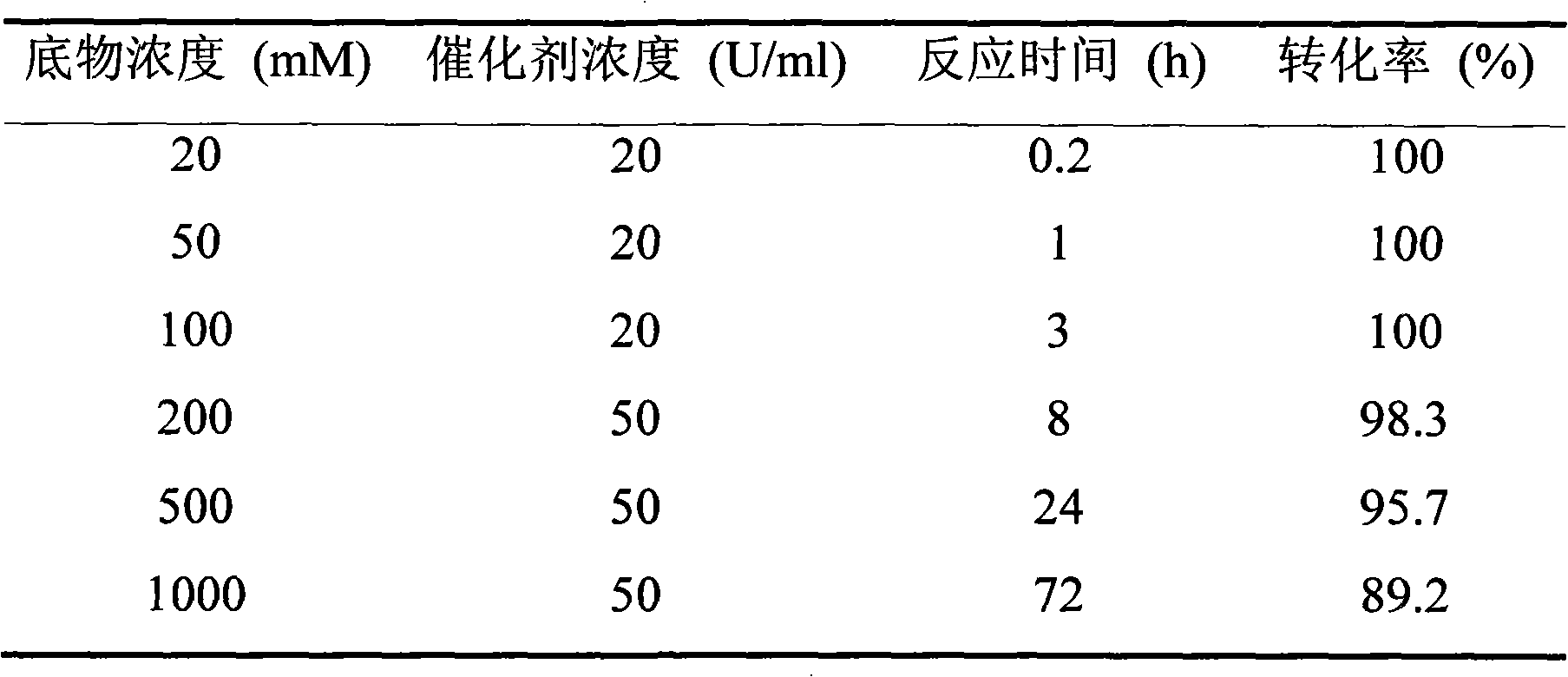

[0035] Example 3 Magnetic Nanomaterials Immobilized Glycolate Oxidase

[0036] Weigh 500mg of magnetic powder, place it in a 100ml round bottom glass flask, add 50ml of Tris-HCl buffer (pH9.0, 100mM, containing 0.1mM FMN), suspend the magnetic powder by ultrasonication, then add 1.0g of glycolic acid oxidase crude enzyme powder (about 297 U), stirred slowly at 15°C and 160 rpm for 24 hours, sucked the obtained immobilized enzyme to the bottom of the container with a magnet, and removed the supernatant with a pipette. The obtained immobilized enzyme was repeatedly washed with 100 ml Tris-HCl buffer solution (pH 9.0, 100 mM) containing 0.1 mMFN until no protein was detected in the washing solution, and stored at 4°C. The immobilized enzyme activity is about 214U / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com