Process for preparing high-purity metallic nickel target of superfine crystal particle

An ultra-fine grain, high-purity technology, applied in the field of metal material pressure processing and heat treatment, can solve the problems of high impurity content, large grain size, coarse grain size, etc., and achieve uniform structure composition and fine grain size , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] For the raw material electrolytic nickel plate with a purity of more than 99.9%, the surface is polished to remove the oxide scale to present a metallic luster, and it is directly cut for rolling.

[0018] The surface-milled slab is cold-rolled at room temperature, and the rolling deformation exceeds 50%, ensuring sufficient deformation to achieve sufficient crushing and uniformity of the internal structure of the nickel ingot.

[0019] The cold-rolled nickel plate was annealed at 600° C. for 30 minutes, and then taken out from the furnace for water cooling to obtain the required nickel target blank. The billet is machined to obtain the required size, and then the required high-purity ultra-fine grain nickel target is obtained.

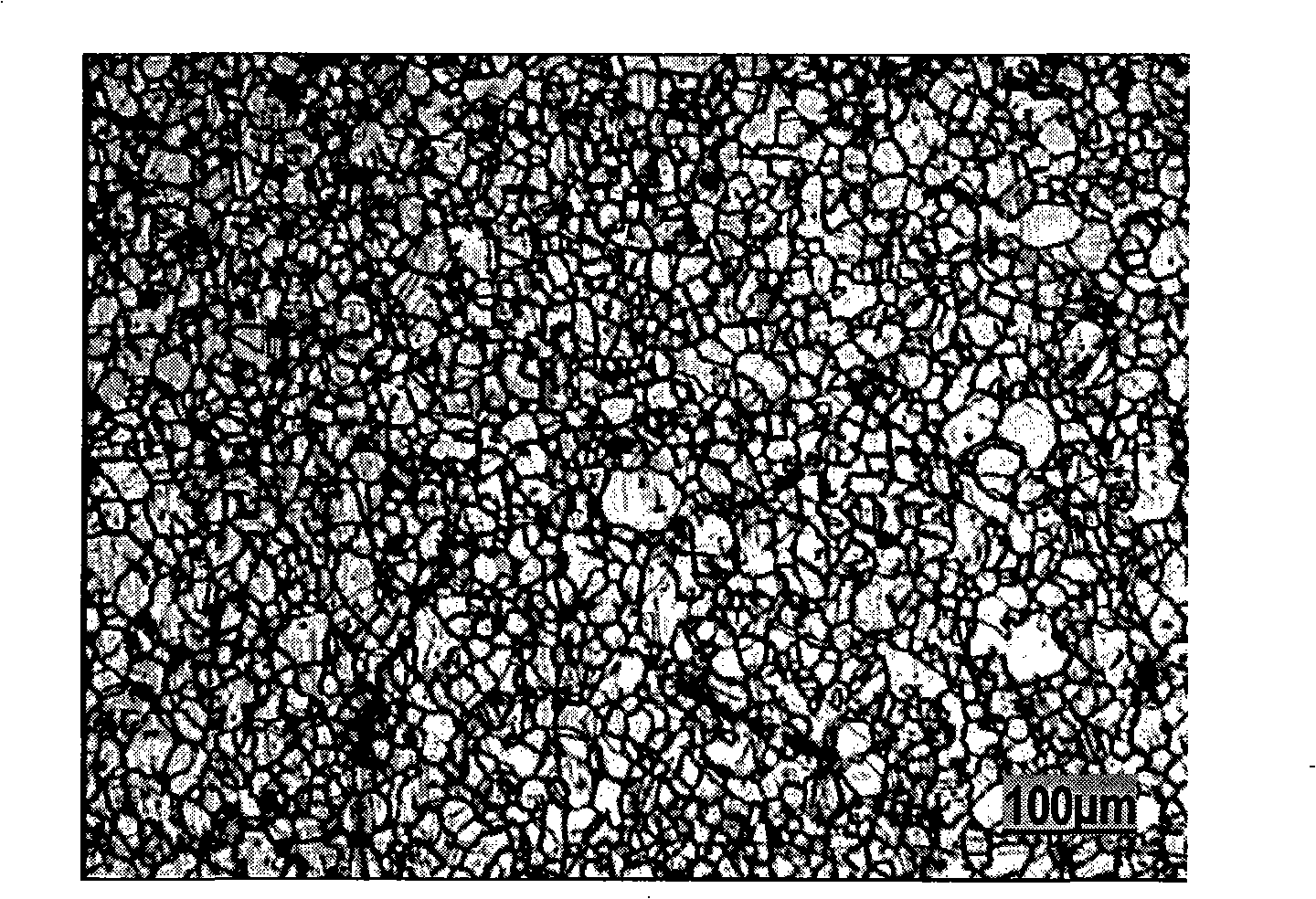

[0020] The obtained nickel target has a purity of 99.96% and an average grain size of 24 μm.

Embodiment 2

[0022] For the raw material electrolytic nickel plate with a purity of more than 99.9%, the surface is polished to remove the oxide scale to present a metallic luster, and it is directly cut for rolling.

[0023] The surface-milled slab is cold-rolled at room temperature, and the rolling deformation exceeds 50%, ensuring sufficient deformation to achieve sufficient crushing and uniformity of the internal structure of the nickel ingot.

[0024] The cold-rolled nickel plate was annealed at 700° C. for 60 minutes, then taken out from the furnace, and cooled to room temperature in air to obtain the required nickel target blank. The billet is machined to obtain the required size, and then the required high-purity ultra-fine grain nickel target is obtained.

[0025] The obtained nickel target has a purity of 99.95% and an average grain size of 27 μm.

Embodiment 3

[0027] For the raw material electrolytic nickel plate with a purity of more than 99.9%, the surface is polished to remove the oxide scale to present a metallic luster, and it is directly cut for rolling.

[0028] The surface-milled slab is cold-rolled at room temperature, and the rolling deformation exceeds 50%, ensuring sufficient deformation to achieve sufficient crushing and uniformity of the internal structure of the nickel ingot.

[0029] The cold-rolled nickel plate was annealed at 800° C. for 120 minutes, and then taken out from the furnace for water cooling to obtain the required nickel target blank. The billet is machined to obtain the required size, and then the required high-purity ultra-fine grain nickel target is obtained.

[0030] The obtained nickel target has a purity of 99.97% and an average grain size of 29 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com