Calcium adsorbing material and its preparation method

An adsorption material, calcium-based technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of long decolorization cycle, etc., achieve the effect of low processing cost, simple preparation method, and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

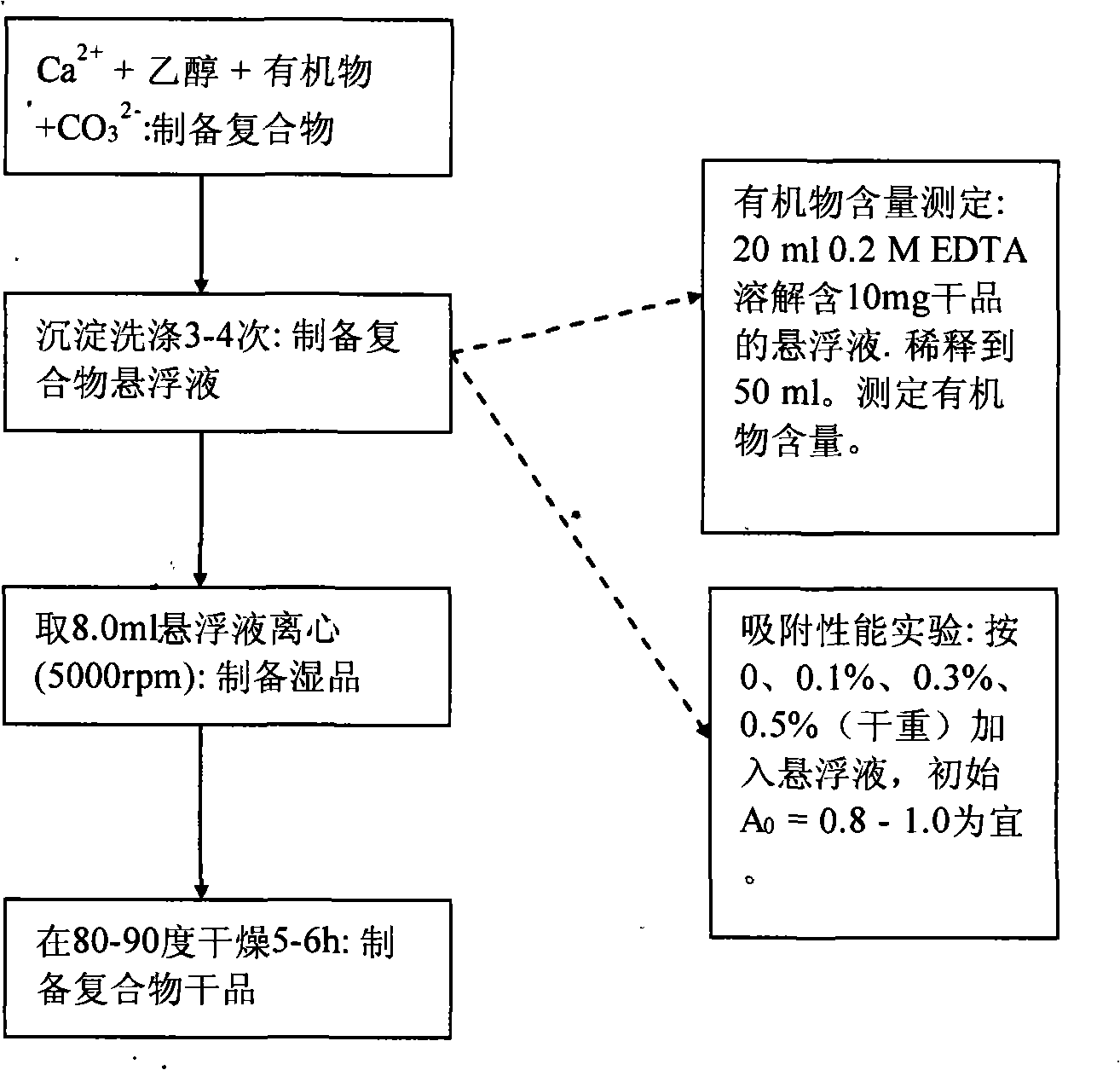

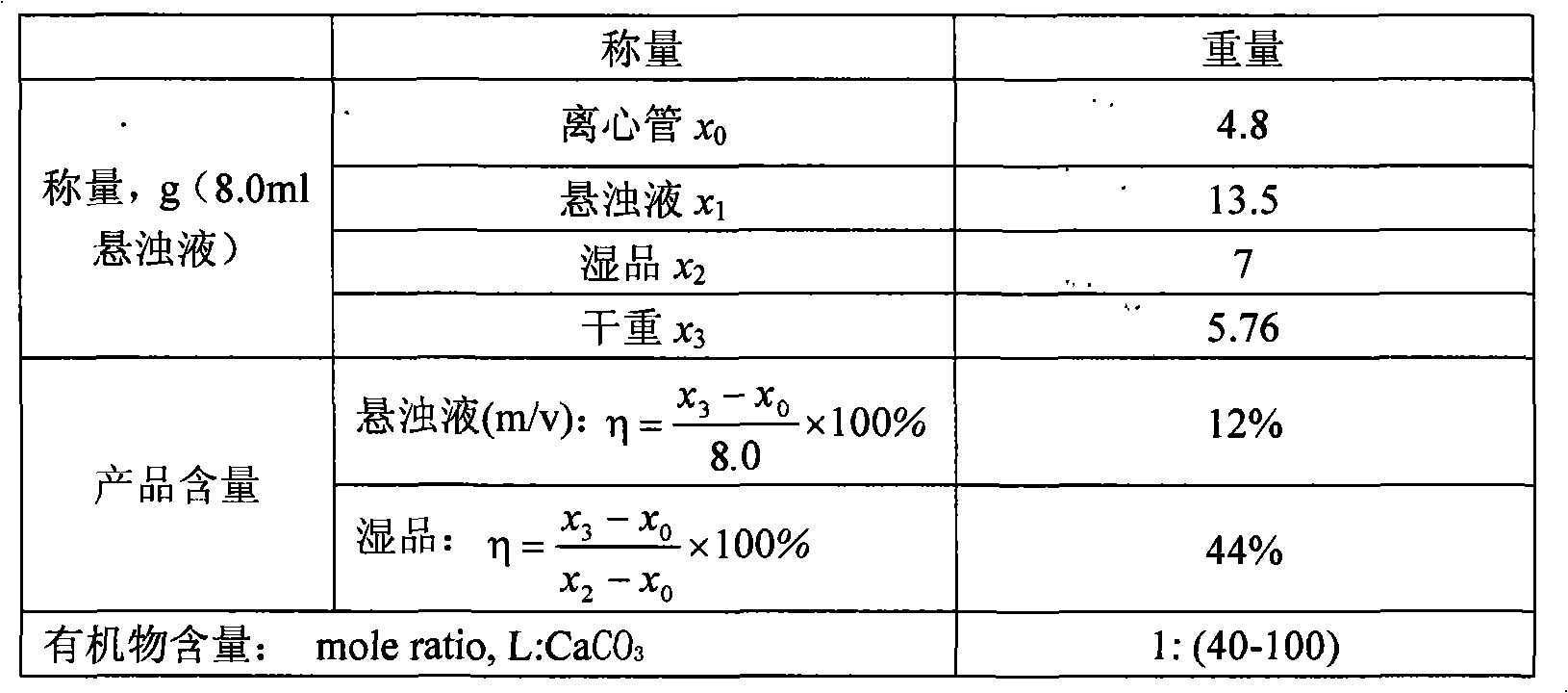

Method used

Image

Examples

example 1

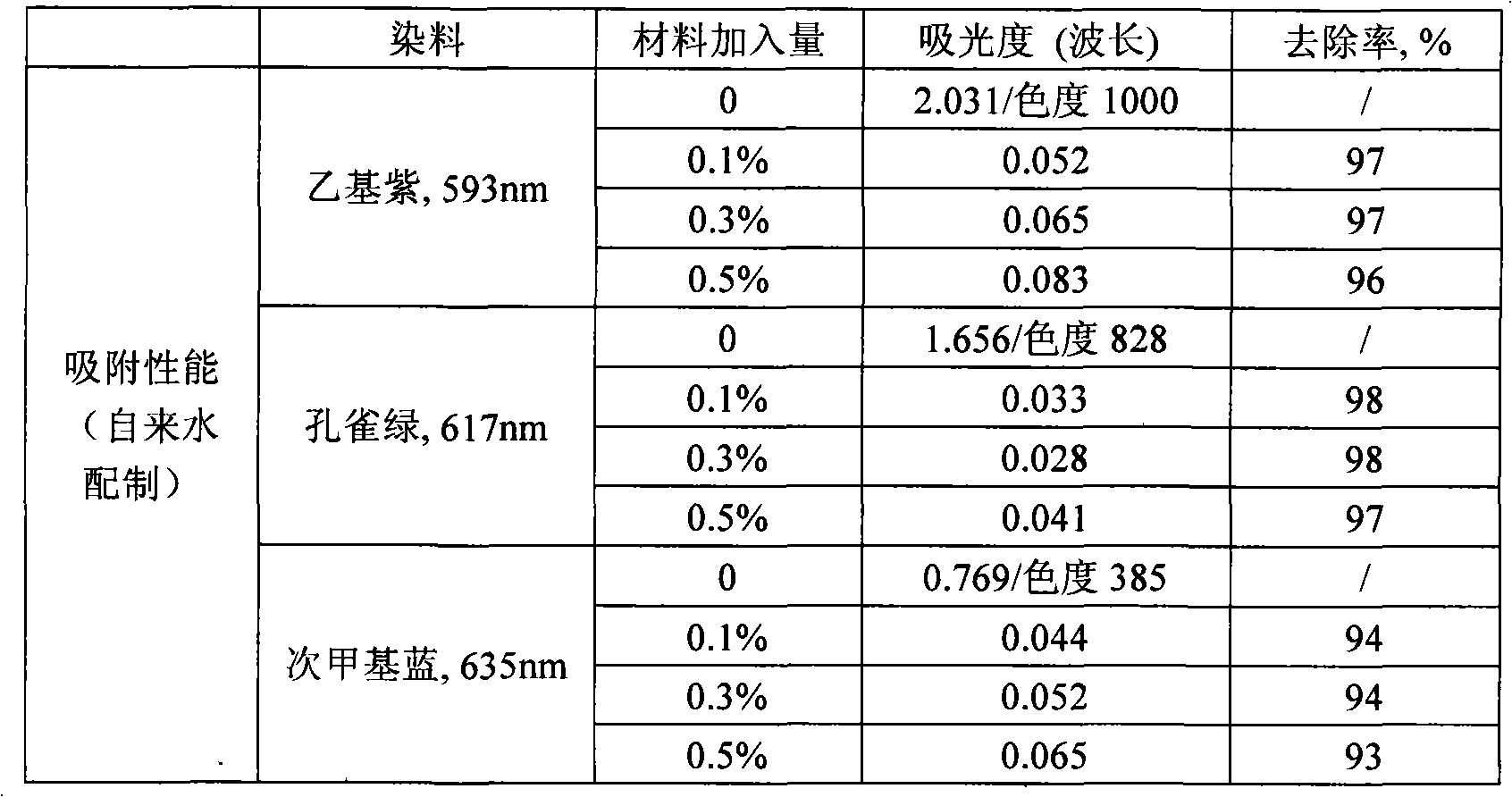

[0020] Example 1: Cationic dye wastewater treatment

[0021] Prepare 3 basic dye samples in a 10ml colorimetric tube: malachite green (chroma 828), ethyl violet (chroma 1000), methylene blue (chroma 385), add 0.1%, 0.3%, 0.5% respectively % adsorption material, after precipitation for 30min, the measured data are shown in Table 1. It can be seen that only 0.1% of the material can absorb more than 94% of the color, and the sedimentation is fast.

[0022] Table 1 Adsorption experimental data of three dyes

[0023]

example 2

[0024] Example 2: POPs wastewater treatment

[0025] Three mixed samples of PAHs were prepared in a 10ml colorimetric tube: 1.49ppm phenanthrene, 1.69ppm fluorene, 1.36ppm biphenyl. Add 0.1%, 0.3%, and 0.5% of adsorbent material respectively, and after 1 h of precipitation, analyze each component, and the calculated data are shown in Table 2. It can be seen that the removal rate of biphenyl is lower than that of phenanthrene and fluorene. Adding 0.5% material can adsorb more than 60% PAHs organic matter. Therefore, the material has a good adsorption effect on hydrophobic organics.

[0026] Table 2 Chromatographic determination data of each component of PAHs

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com