Composition for reducing discharge of NOx in FCC stack gas

A technology for regenerating flue gas and composition, applied in catalytic cracking, petroleum industry, cracking and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026]The preparation method of the composition provided by the present invention can adopt any existing method, such as a dipping method, a mixing and gelling method or a combination of the two. For example, prefabricated alumina microspheres can be impregnated with phosphorus-containing compounds, compounds containing the IB and IIB group metal elements, compounds containing the metal additive elements, and compounds containing the rare earth elements, and dried and calcined. Composition particles are obtained; the above compounds can also be added to the slurry containing the oxide carrier (for example, alumina carrier), mixed and beaten, and then spray-dried to obtain microsphere particles, and the composition particles are obtained after roasting; or the above-mentioned One or more of the compounds are added to the slurry containing the oxide carrier (such as alumina), mixed and beaten to form a gel, and spray-dried to obtain microsphere particles. After the microsphere pa...

Embodiment 1-6

[0035] This embodiment illustrates the reduction of flue gas NO provided by the present invention x Preparation of Emission Composition.

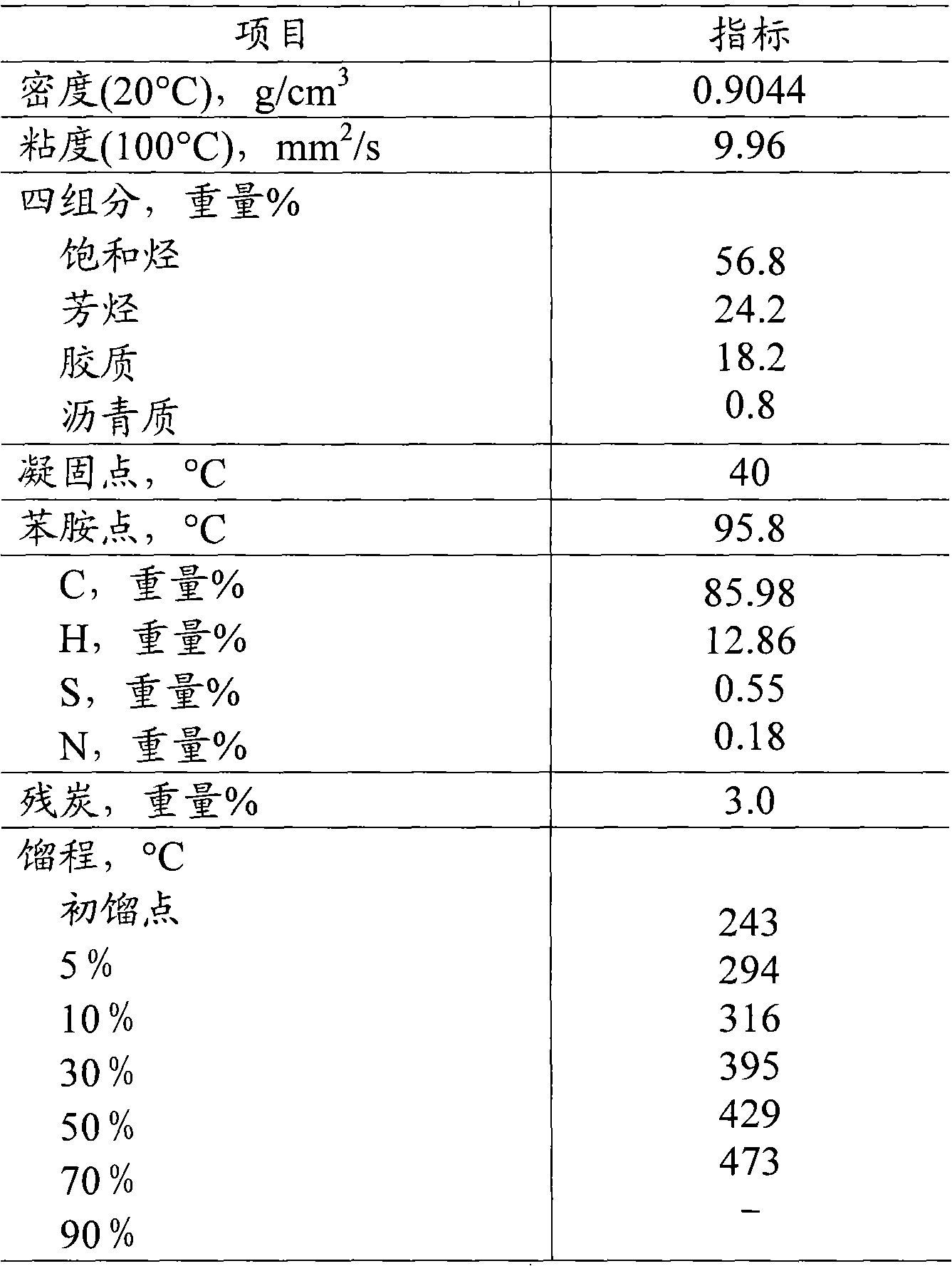

[0036] Pseudo-boehmite, phosphorus-containing compound and water are mixed and beaten (the solid content of the slurry is 12% by weight), acidified by adding hydrochloric acid at a ratio of 0.10 by weight of hydrochloric acid and aluminum oxide, beaten, and ferric chloride and / or V 2 o 5 - oxalic acid complex solution (or not), beating, adding rare earth solution, beating, and then spray drying to obtain microsphere particles.

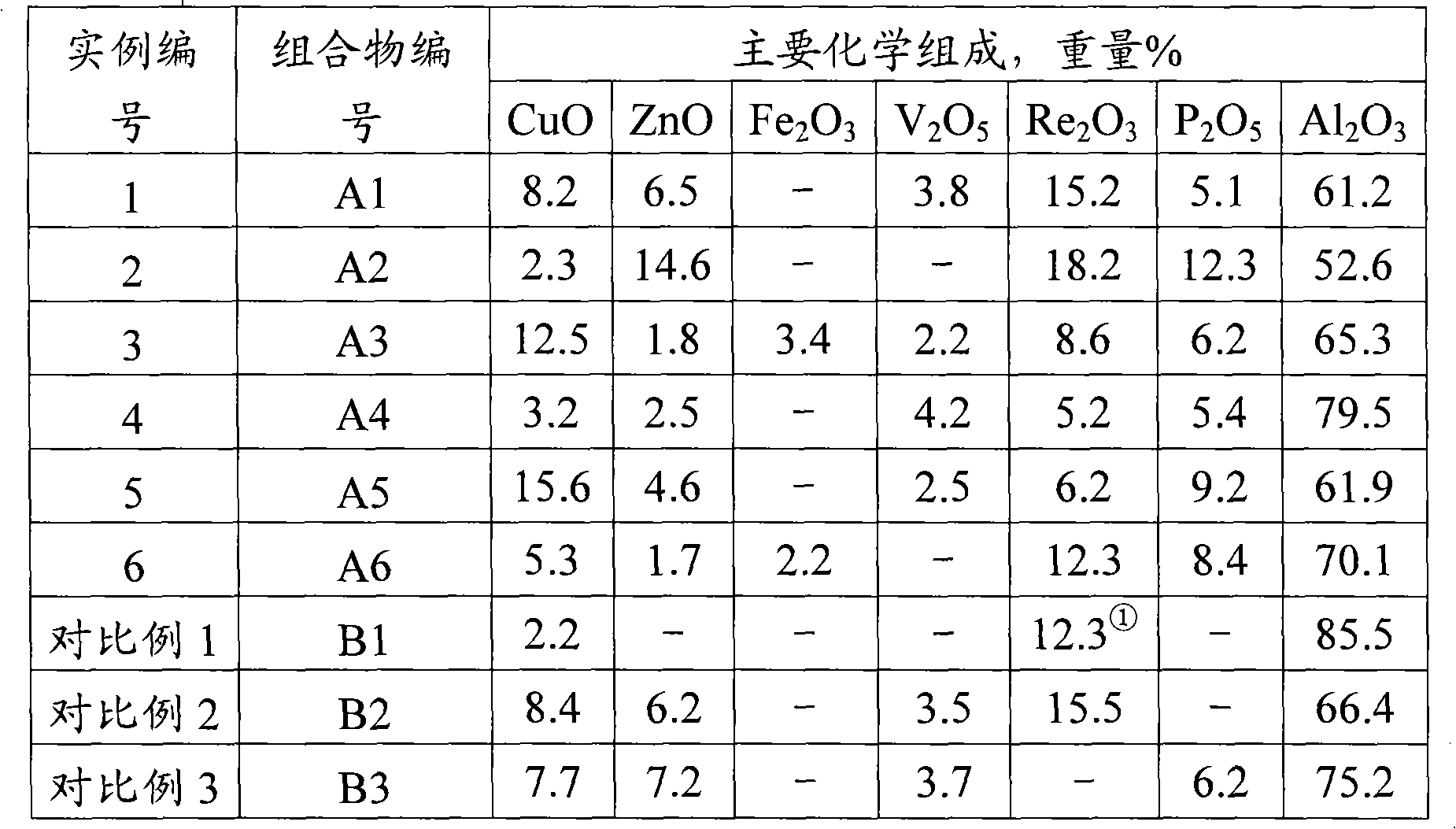

[0037] The microsphere particles are calcined at 600°C for 1 hour in a muffle furnace, then saturated with cupric chloride and / or zinc chloride solution to impregnate the microspheres, then dried at 120°C, and then calcined at 600°C for 1 hour to obtain Compositions A1-A6 provided by the present invention.

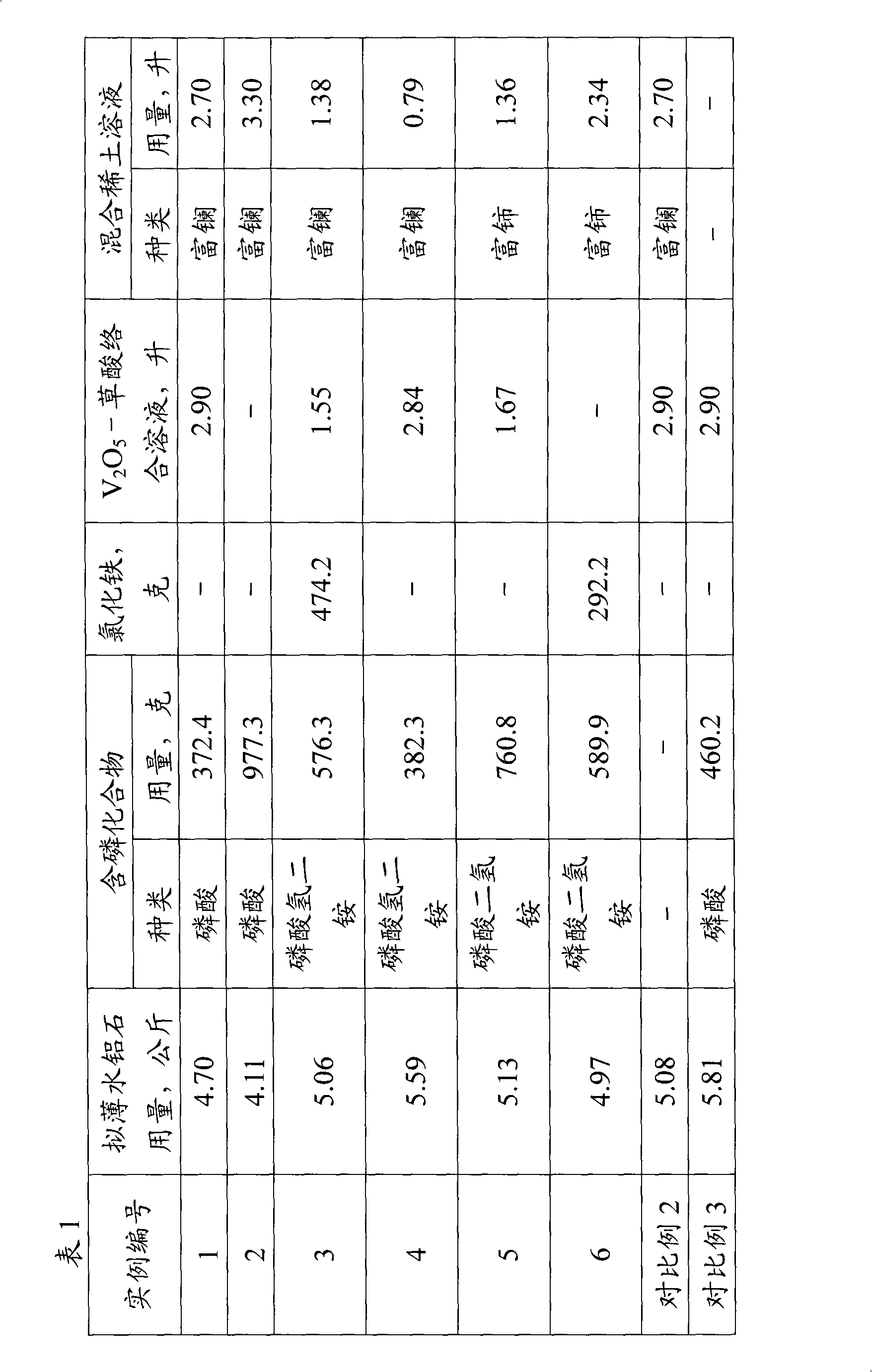

[0038] During the preparation of compositions A1-A6, pseudo-boehmite, types and amounts of phosphorus-con...

Embodiment 7-12

[0062] This group of examples illustrates that compositions A1-A6 provided by the invention have a significant effect on NO in catalytic cracking regenerated flue gas. x Effects on emissions and product distribution.

[0063] Compositions A1-A6 were aged for 12 hours at 800° C. under 100% water vapor atmosphere, then mixed with the industrial balancing agent respectively, and evaluated in a small fixed fluidized bed device. In the mixture, the content of the composition of the present invention accounts for 4% by weight of the total weight of the mixture.

[0064]NO in flue gas x The concentration and its changes are listed in Table 5, and the distribution of catalytic cracking products is listed in Table 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com