Method for preparing biological diesel oil with series double-fixed bed and catalysis of solid catalyst

A solid catalyst and biodiesel technology, which is applied in the preparation of biological raw materials, biofuels, and liquid hydrocarbon mixtures, can solve the problems of short reaction life, large waste water, and increased production costs, so as to reduce the production process and expand the scope of sources , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

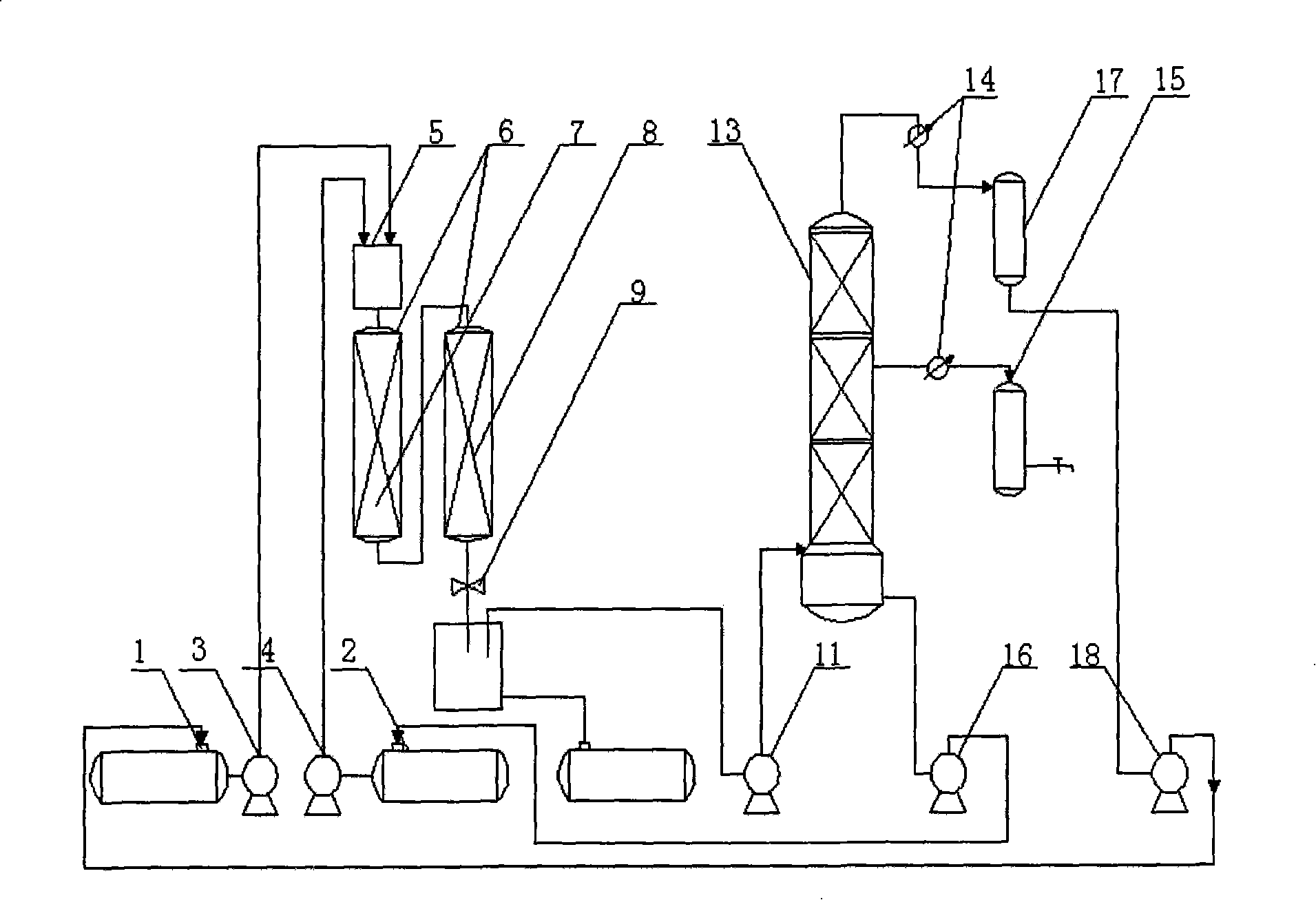

[0019] Embodiment 1: take the cottonseed oil of acid value 1.94mgKOH / g as raw material to prepare biodiesel,

[0020] (1) Cottonseed oil and methanol are filled respectively in methanol storage tank 1; in the grease raw material storage tank 2, the cottonseed oil is pumped into the premixing heater 5 through the seamless steel pipe with the flow rate of 9.75mL / min with the grease metering pump 4, At the same time, another methanol metering pump 3 is used to pump methanol into the premix heater 5 at a flow rate of 12:1 molar ratio of alcohol to oil as the initial reaction material. The preheater temperature is controlled at 60°C.

[0021] (2) After the reactant is preheated and mixed by the preheater, it enters the fixed bed 6 filled with a self-made solid acid catalyst and contacts with the solid acid catalyst 7 to undergo a heterogeneous reaction, so that the free fatty acid in the raw material oil is esterified, thereby reducing the amount of the raw material oil. acid valu...

Embodiment 2

[0024] (5) The excess low-carbon alcohol recovered at the top of the fractionating tower is directly pumped back to the oil raw material storage tank 2 for recycling, and unreacted oil or other impurities with high boiling points are collected at the bottom of the fractionating tower for removal of impurities before recycling. Embodiment 2: Preparation of biodiesel with waste cooking oil with an acid value of 38mgKOH / g as raw material

[0025] (1) Fill waste cooking oil and methanol respectively in methanol storage tank 1; in grease raw material storage tank 2, use grease metering pump 4 to pump cottonseed oil into premix heater 5 through seamless steel pipe with a flow rate of 15.3mL / min At the same time, another methanol metering pump 3 is used to pump methanol into the premixed heater 5 at a flow rate of 15:1 in the molar ratio of alcohol to oil as the initial reaction material. The preheater temperature is controlled at 60°C.

[0026] (2) After the reactant is preheated a...

Embodiment 3

[0030] Embodiment 3: take the palm oil of acid number 13mgKOH / g as raw material preparation biodiesel

[0031] (1) palm oil and methyl alcohol are filled respectively in methanol storage tank 1; in grease raw material storage tank 2, with the flow rate of 21.3mL / min, cottonseed oil is pumped into premix heater 5 through seamless steel tube with grease metering pump 4, At the same time, another methanol metering pump 3 is used to pump methanol into the premix heater 5 at a flow rate of 12:1 molar ratio of alcohol to oil as the initial reaction material. The preheater temperature is controlled at 60°C.

[0032](2) After the reactant is preheated and mixed by the preheater, it enters the fixed bed 6 filled with solid acid catalyst and contacts with the solid acid catalyst 7 to undergo a heterogeneous reaction, esterifying the free fatty acid in the raw oil to reduce the acid value. The reaction temperature is controlled at 100°C, that is, the reaction pressure is correspondingly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com