Preparation for effective component of turmeric

A technology for effective components and turmeric, applied in the field of extraction and preparation of effective components of turmeric, can solve the problems of inability to large-scale production, low product purity, poor reproducibility, etc., and achieves suitable for industrialized large-scale production and small organic solvent residues. , highly reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

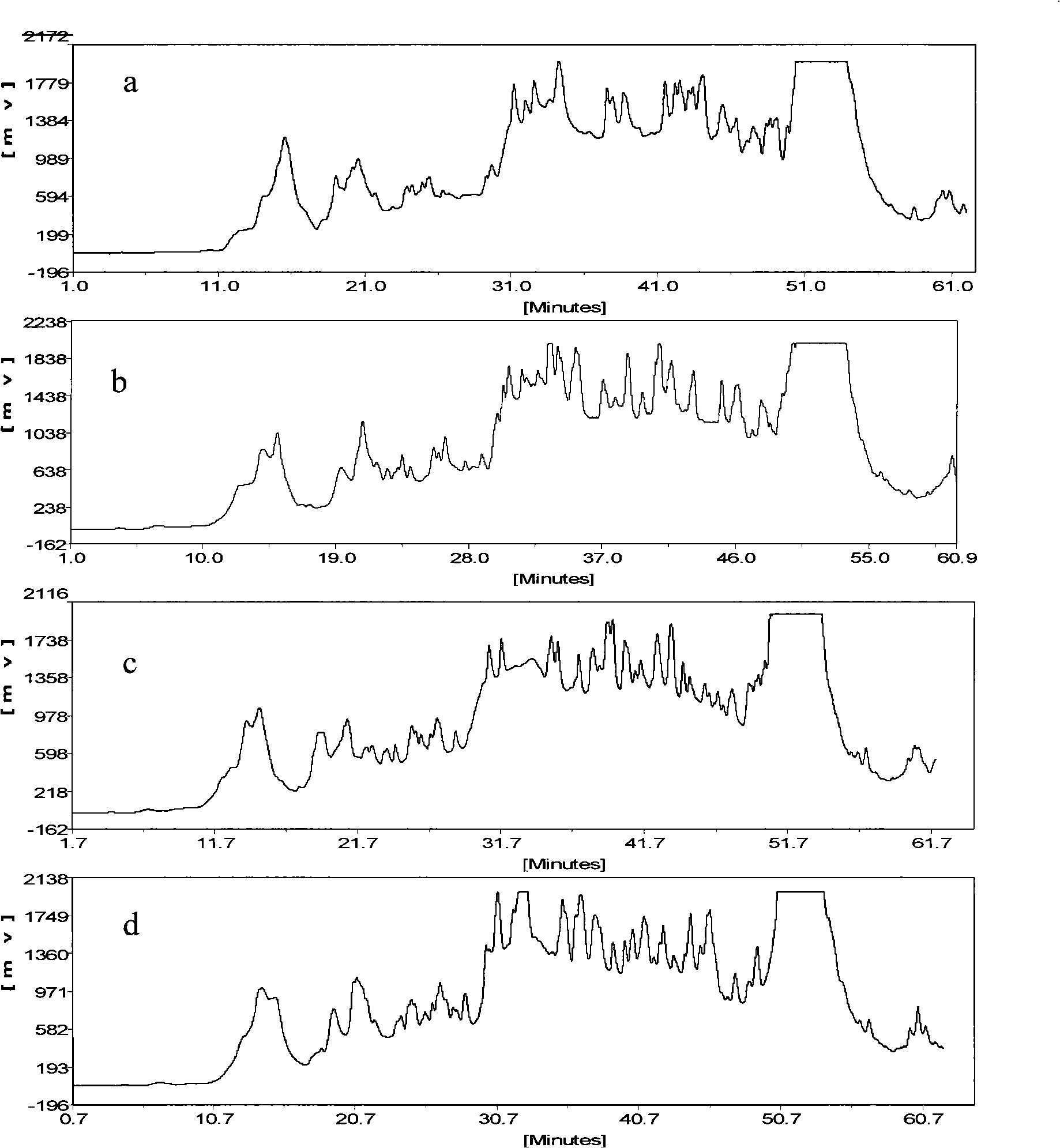

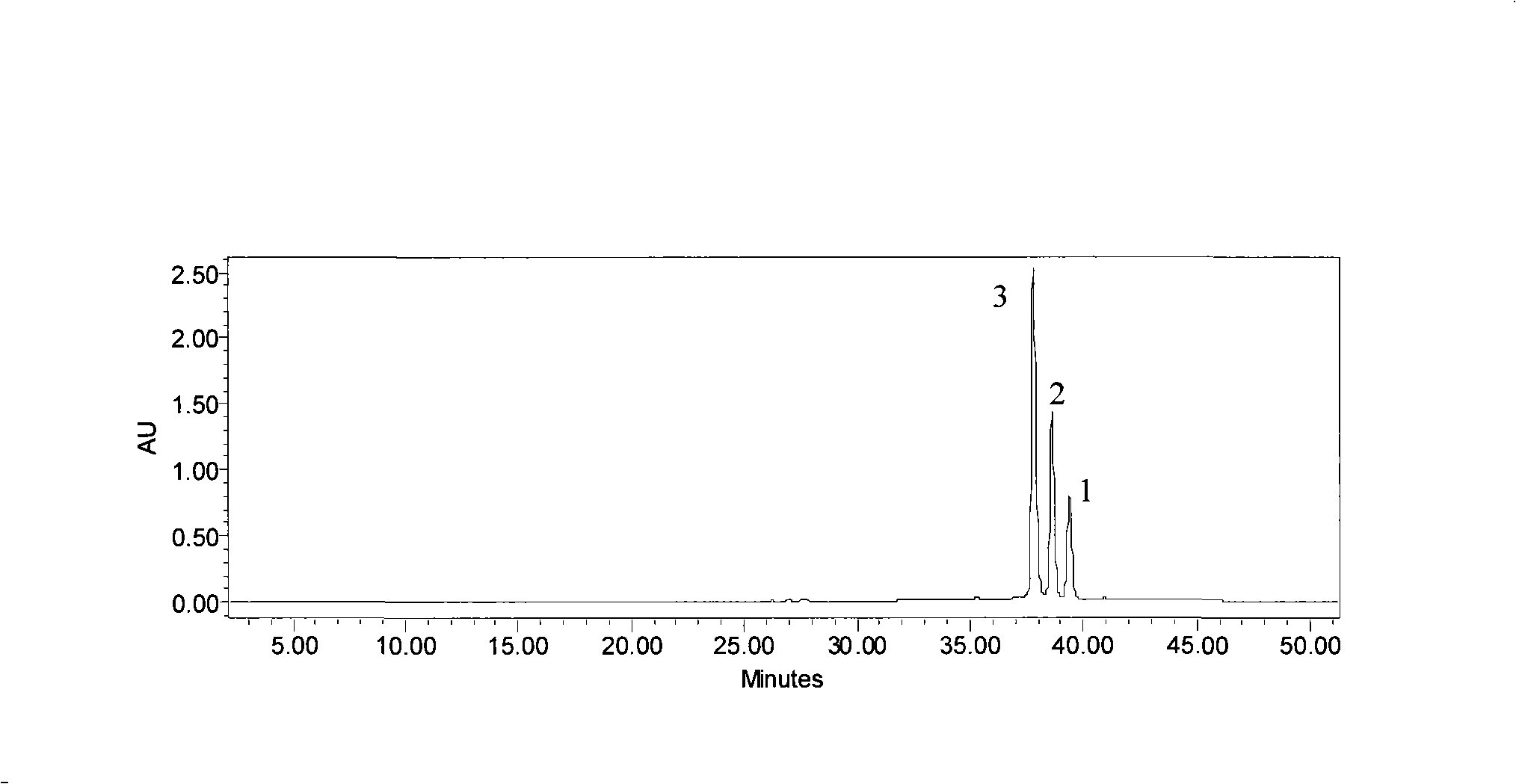

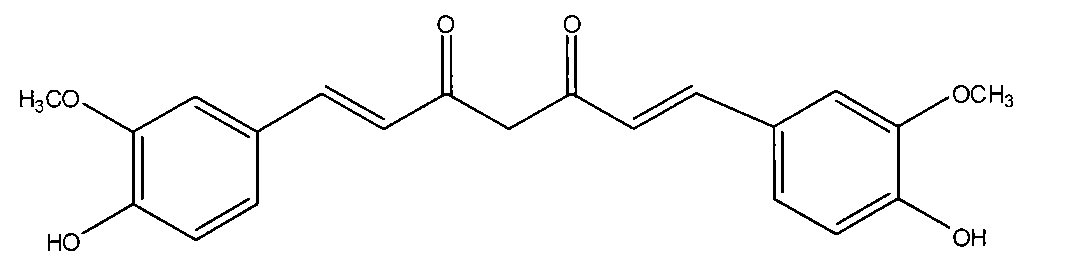

[0019] Grind the original medicinal material of turmeric, weigh 1 kg quantitatively, put it in a 20-liter extraction tank, add 10 liters of 95% ethanol to soak for 1 day, filter, save the filtrate for later use, add 10 liters of 95% ethanol to the filter residue and soak for 1 day, filter , the filtrate was combined with the first time, and the filter residue was discarded. The extract was concentrated to 150 ml by rotary evaporation to obtain the alcohol-extracted fraction of curcuma.

[0020] Load 10 L of processed Rohm and Haas XAD-4 macroporous resin into the macroporous resin chromatography system, and dry-load the curcumin alcohol extraction fraction on the macroporous resin chromatography column. First use 4 times column volume 40L 50% ethanol to elute the column body, discard the eluate, then use 4 times column volume 40L 80% ethanol to elute, save the eluate, and concentrate to a solid content of 0.3 g / ml, pass 0.22 micron filter membrane, obtains 50 milliliters of t...

Embodiment 2

[0031] Grind the original turmeric medicinal material, weigh 0.5 kg quantitatively, put it in a 10-liter extraction tank, add 6 liters of 70% ethanol to soak for 2 days, filter, save the filtrate for later use, add 6 liters of 70% ethanol to the filter residue and soak for 1 day, filter , the filtrate was combined with the first time, and the filter residue was discarded. The extract was concentrated to 70 ml by rotary evaporation to obtain the alcohol-extracted fraction of curcuma.

[0032] Put 5 L of processed Rohm and Haas XAD-4 macroporous resin into the macroporous resin chromatography system, and dry-load the curcumin alcohol extraction fraction on the macroporous resin chromatography column. First, the column was eluted with 6 times column volume of 30L 40% ethanol, and the eluate was discarded, then eluted with 6 times column volume of 30L 85% ethanol, and the eluate was stored and concentrated to a solid content of 0.2 g / ml. Cross 0.22 micron filter membrane, obtain ...

Embodiment 3

[0035] Grind the original medicinal material of turmeric, weigh 5 kg quantitatively, put it in a 100-liter extraction tank, add 60 liters of 80% ethanol to soak for 2 days, filter, save the filtrate for later use, add 60 liters of 80% ethanol to the filter residue and soak for 2 days, filter , the filtrate was combined with the first time, and the filter residue was discarded. The extract was concentrated by rotary evaporation to 700 ml to obtain the curcumin alcohol-extracted fraction.

[0036] Load 50 L of processed Rohm and Haas XAD-4 macroporous resin into the macroporous resin chromatography system, and dry-load the curcumin alcohol extraction fraction on the macroporous resin chromatography column. First use 3 times the column volume of 150L 60% ethanol to elute the column body, discard the eluate, and then use 3 times the column volume for 150L 95% ethanol to elute, save the eluate, and concentrate it to a solid content of 0.5 g / ml. 0.45 micron filter membrane, obtains...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com