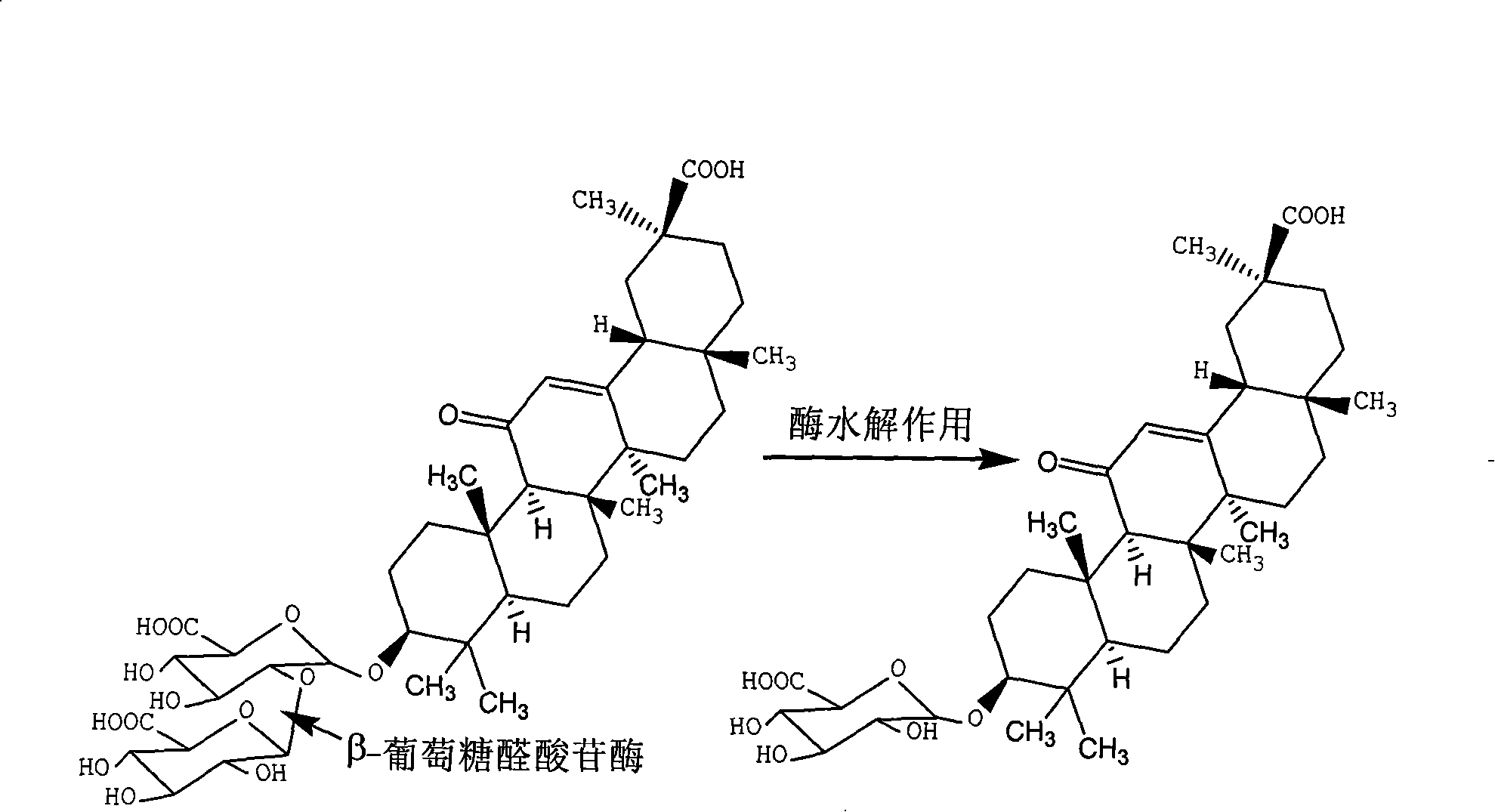

Method for continuous flow upstream abstraction purification of glycyrrhiza hypo-glycosides in glycyrrhizic acid biotransformation solution

A technology of biotransformation and glycyrrhetin, applied in the direction of steroids, organic chemistry, etc., can solve the problems of prolonged extraction reaching equilibrium, hindering the transfer of glycyrrhetin molecules, reducing the extraction efficiency of glycyrrhetin, etc., and prolonging the time to reach , easy continuous operation, fast and effective separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

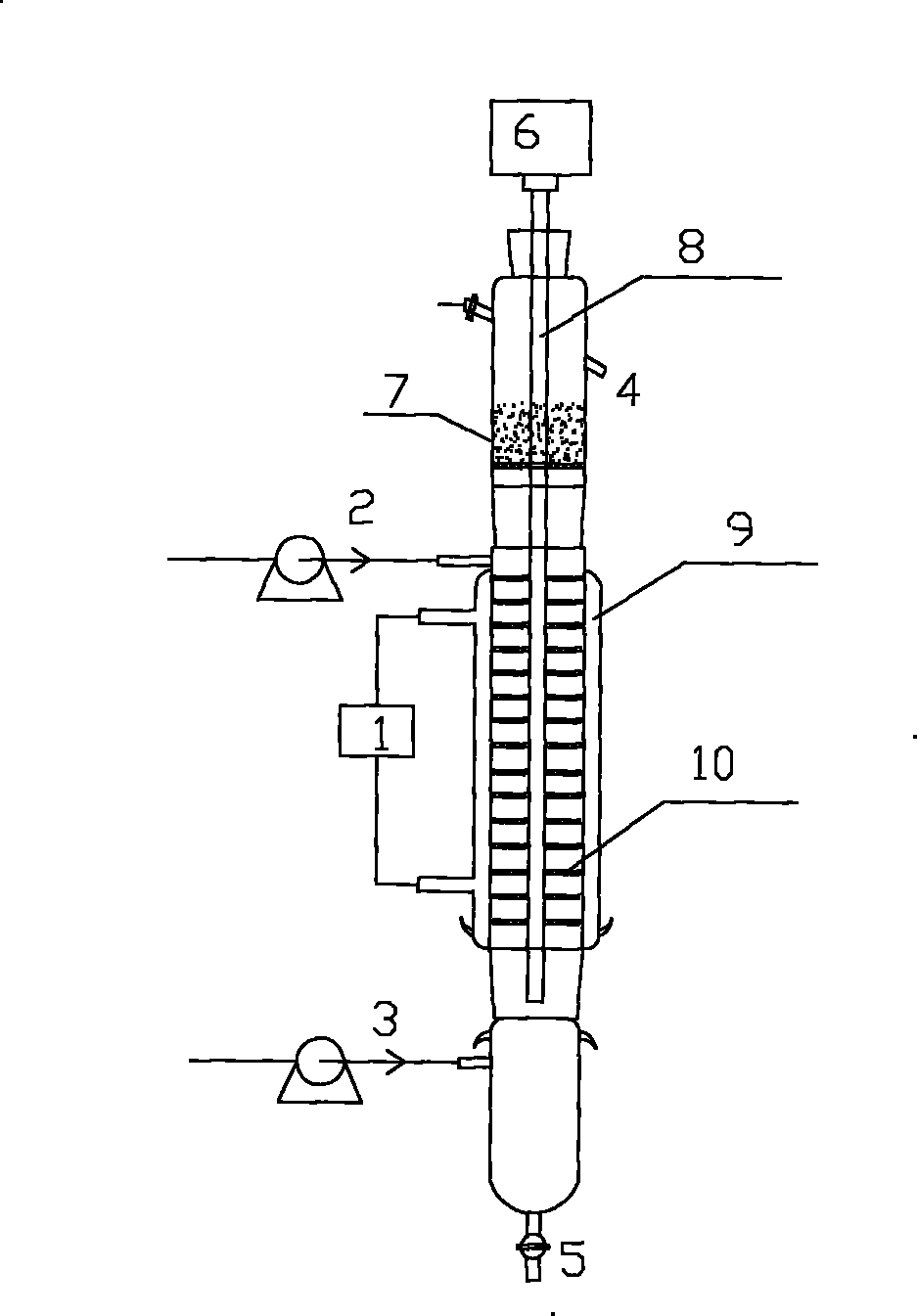

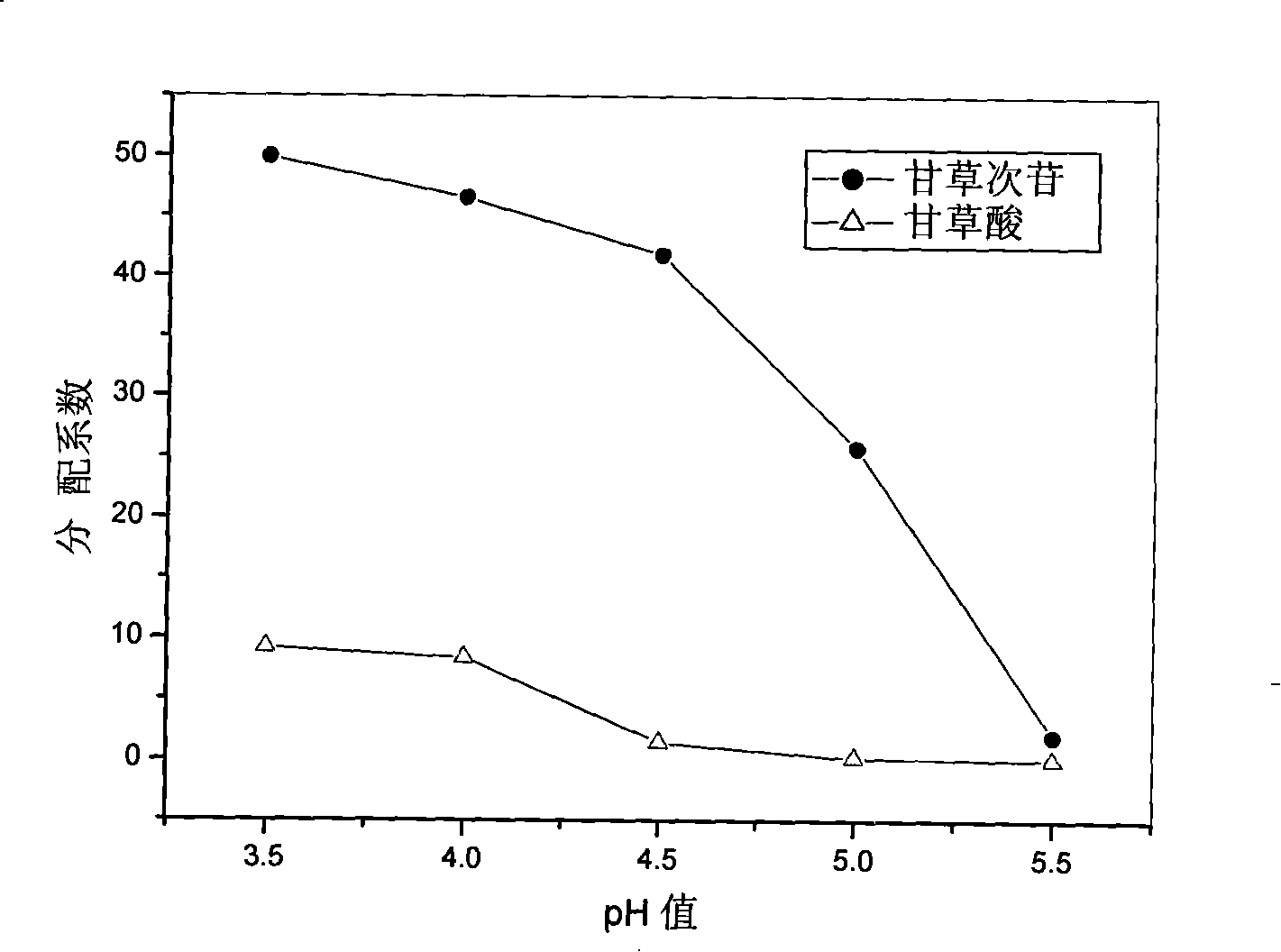

[0033] For the process of continuous countercurrent extraction and purification of glycyrrhetin, refer to the attached image 3 : the circulating water 1 of certain temperature is pumped into the turntable tower jacket 9 to keep the constant temperature; after adjusting the pH value of the glycyrrhizic acid biotransformation liquid with a certain glycyrrhetin content, it is added to the turntable tower with a certain flow rate from the heavy phase feeding port 2 At the same time, the extractant is fed into the tower body from the light phase feed port 3 at a flow rate corresponding to the heavy phase and is in countercurrent contact with the heavy phase. At the same time, the motor 6 drives the rotating shaft 8 and the turntable 10 to rotate to control a certain speed to promote the two-phase liquid. Fully mixed, Glycyrrhizin is separated from the aqueous phase solution and enters the organic extractant to form the upward aggregation of the extraction phase; after the extractio...

Embodiment 2

[0038] The implementation method and detection method of the present embodiment are the same as in Example 1, and the concrete parameters of implementation are as follows:

[0039] The extractant is ethyl acetate, the content of glycyrrhizin is 1.0g / L, the pH value is 4.5, the extraction temperature is 45°C, the flow rate of glycyrrhizic acid biotransformation solution is 15L / h, the flow ratio of extractant and glycyrrhizinic acid biotransformation solution is 1.5, the rotary speed of the turntable is 300rpm, and the solvent recovery method is vacuum distillation.

[0040] The yield of the product glycyrrhizin is 87.1%, and the purity is 95.2%.

Embodiment 3

[0042] The implementation method and detection method of the present embodiment are the same as in Example 1, and the concrete parameters of implementation are as follows:

[0043] The extractant is propyl acetate, the content of glycyrrhizin is 1.5g / L, the pH value is 4.8, the extraction temperature is 50°C, the flow rate of glycyrrhizic acid biotransformation solution is 20L / h, the flow ratio of extractant and glycyrrhizic acid biotransformation solution is 0.5, the feed liquid flow rate is 10L / h, the turntable speed is 200rpm, and the solvent recovery method is distillation.

[0044] The yield of the product glycyrrhizin is 89.2%, and the purity is 96.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com