Novel oilfield sewage disposal coagulant

An oilfield sewage and coagulant technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of substandard water quality, short residence time, harsh hydraulic conditions, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

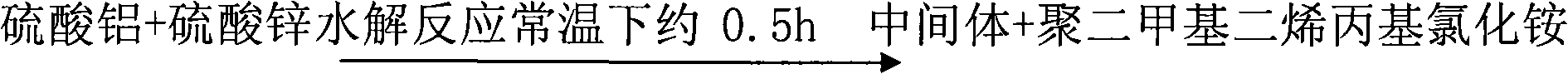

Method used

Image

Examples

Embodiment 1

[0024] The weight percent composition of the coagulant is 20% of aluminum sulfate, 4% of zinc sulfate, 0.5% of polydimethyl diallyl ammonium chloride, and the rest is water. This formula is suitable for the purification treatment of general oilfield sewage, and the effect is stable. Table 1 shows the results of a field application test in a certain unit of Xinjiang Oilfield Company. After treatment, the suspended solids content, oil content, and concentration of the drug added to the water all decreased significantly (the dosage of the drug was calculated according to the effective content).

[0025] Table 1 Comparison of water quality in field application tests of different agents

[0026]

Embodiment 2

[0028] The weight percent composition of the coagulant is 10% of aluminum sulfate, 10% of zinc sulfate, 0.5% of polydimethyl diallyl ammonium chloride, and the rest is water. This formula is suitable for the purification treatment of oily sewage containing hydrogen sulfide (<10mg / L), and the effect is stable. Table 2 shows the results of the simulated test of produced water purification in a certain unit of Xinjiang Oilfield Company. The results show that, compared with polyaluminum chloride (PAC), the dosage concentration (the dosage of the dosage is calculated according to the effective content) is reduced. Under these conditions, the suspended matter content, oil content and oil content of the treated water are significantly reduced, and it also has desulfurization effect.

[0029] Table 2 Comparison of water quality in field simulation tests of different agents

[0030]

[0031]

Embodiment 3

[0033] The weight percent composition of the coagulant is 20% of aluminum sulfate, 2% of zinc sulfate, 0.2% of polydimethyl diallyl ammonium chloride, and the rest is water. This formula is suitable for purification treatment of heavy oily sewage with high temperature. Table 3 shows the evaluation results of this coagulant on the purification effect of heavy oil sewage in a certain unit of Xinjiang Oilfield Company. The results show that when the dosage of the new oilfield sewage coagulant exceeds 120mg / L, the water quality after treatment has little difference, and the suspended solids The content and oil content have been reduced to a very low level. Compared with polyaluminum chloride (PAC), the content of suspended solids in the treated water is obviously lower under the same dosing concentration.

[0034] Table 3 Comparison of purification effects of different agents on heavy oil sewage

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com