Process for extracting two kinds of yeast bilesalt hydrolase and production technology of functional posset

A technology of bile salt hydrolase and extraction method, applied in the production field of functional milk wine and kefir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

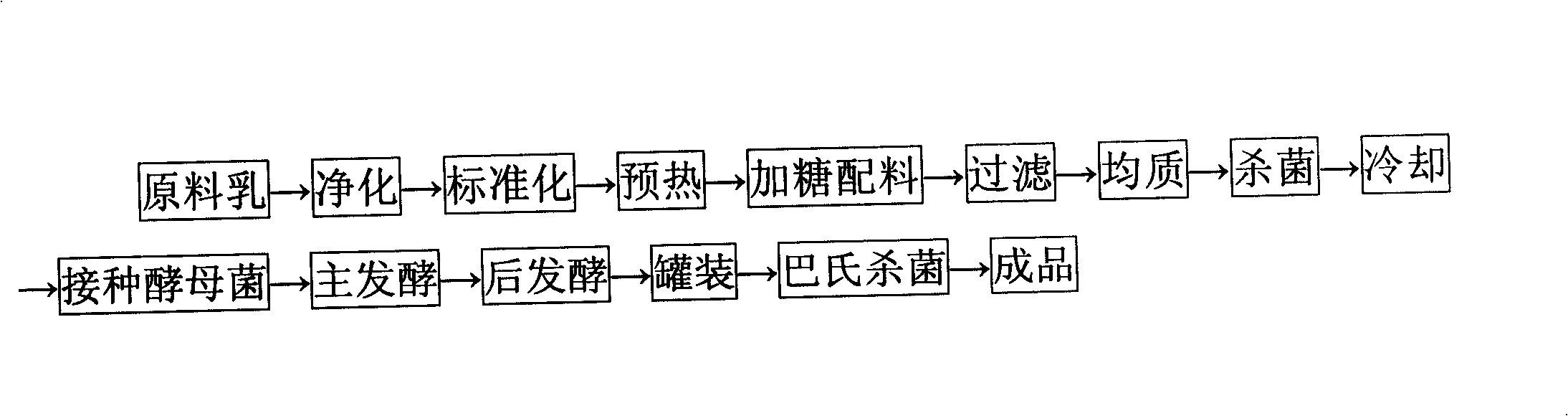

Method used

Image

Examples

Embodiment 1

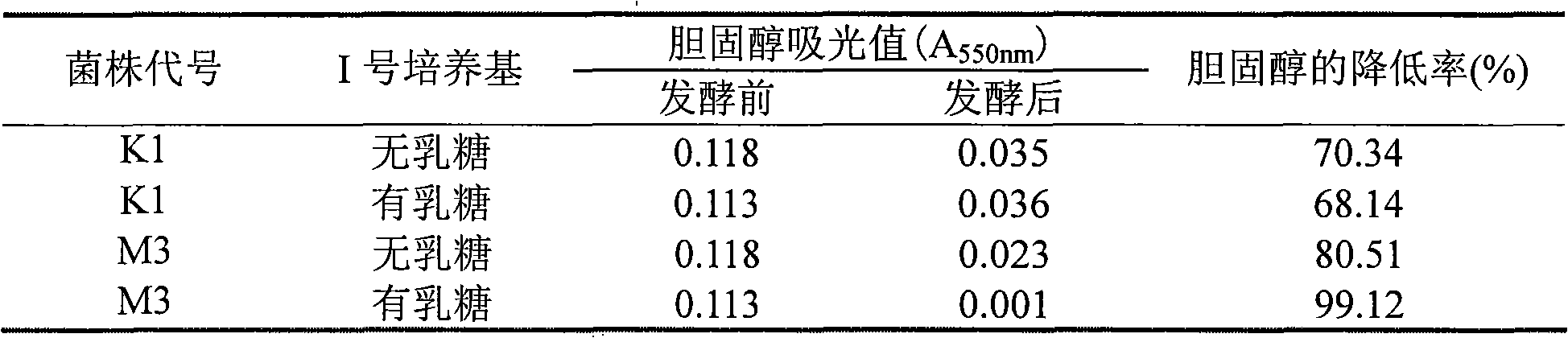

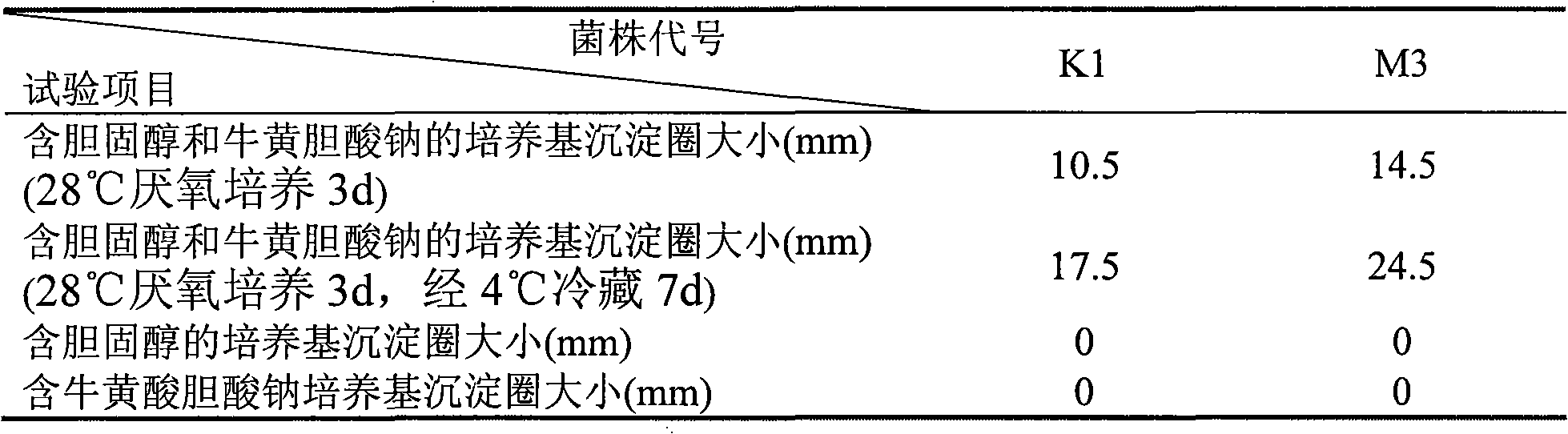

[0029]Example 1. Screening and Identification of Kluyveromyces marxianus K1 and M3 Strains with High Efficiency in Lowering Cholesterol and High Production of Bile Salt Hydrolase

[0030] 1. Screening of high-efficiency cholesterol-lowering and high-production bile salt hydrolase strains

[0031] Take 5mL of the filtrate of Zangling mushroom and pour it into 45mL sterile saline with glass beads, shake it fully for 30min to make a bacterial suspension, and then dilute it 10 times to 10 -4 ~10 -6 diluted bacterial solution. The plates were inoculated by the dilution pouring method, poured into the potato lactose selective medium containing antibiotics, and cultured at 28°C for 2-3 days. According to the colony characteristics of the yeast and the results of microscopic examination of the water immersion slides, the target colonies on the above plate were streaked and inoculated on the corresponding slant medium, and cultured at 28°C for 2-3 days. Transfer to inoculate in pota...

Embodiment 2

[0051] Example 2, Utilizing Kluyveromyces marxe K1 and M3 to Extract Bile Salt Hydrolase

[0052] 1. Fermentation process conditions for high production of bile salt hydrolase

[0053] Medium components (w / v) for cultivating Kluyveromyces marxii K1 and M3 high-yielding bile salt hydrolase: lactose 2%, potato 20% (potatoes are peeled and cut into pieces, boiled with water for 10-20min, covered with double gauze) filter), agar 1.5%, distilled water 1000mL, 0.07MPa sterilization for 20min.

[0054] Fermentation process conditions for high production of bile salt hydrolase:

[0055] M3 strain: the fermentation temperature is 32° C., the fermentation time is 24 hours, the initial pH value of the medium is 6.0, and the inoculation amount is 1%.

[0056] K1 strain: the fermentation temperature is 32° C., the fermentation time is 18 hours, the initial pH value of the medium is 6.0, and the inoculation amount is 2%.

[0057] Under the optimized fermentation conditions, the enzyme ac...

Embodiment 3

[0067]The activity of the bile salt hydrolyzing enzyme is measured by the amount of amino acids released after the degradation of the combined bile salt. That is, the enzyme activity is directly proportional to the amount of amino acid produced. The content of amino acids can be determined by ninhydrin chromogenic method. Take 2mL of enzyme reaction solution, add 1mL of ninhydrin color reagent, mix well, heat in boiling water bath for 16min, cool with tap water, add 5mL of diluent, shake well, and use 2mL of distilled water instead of enzyme reaction solution as the blank control to adjust to 0 , Measure the absorbance value A at 570nm (the generated color is stable within 60min, preferably completed within 30min). The amino acid produced by bile salt hydrolase at 1 μmol per minute was defined as an enzyme activity unit. Example 3. Production of functional milk wine by utilizing bacterial strains that are highly effective in lowering cholesterol and producing bile salt hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com