Method for catalytic synthesis of garlic oil of different combinations by phase-transfer method

A technology of phase transfer catalysis and phase transfer catalyst, which is applied in the fields of organic chemistry, hydrogenated polysulfide/polysulfide preparation, etc., can solve problems such as residues and affect product quality, and achieve improved conversion rate, shortened reaction time, and product yield. The effect of high rate and content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

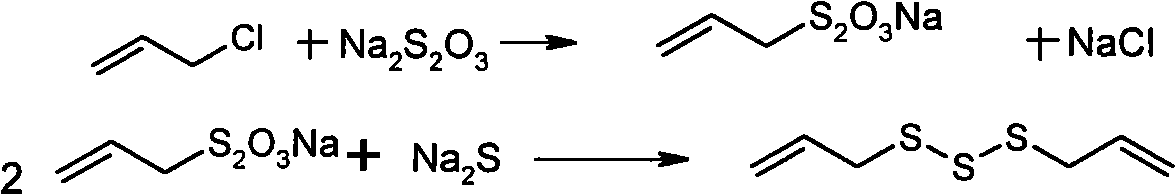

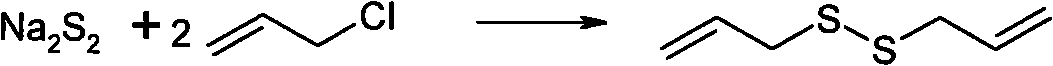

Method used

Image

Examples

Embodiment 1

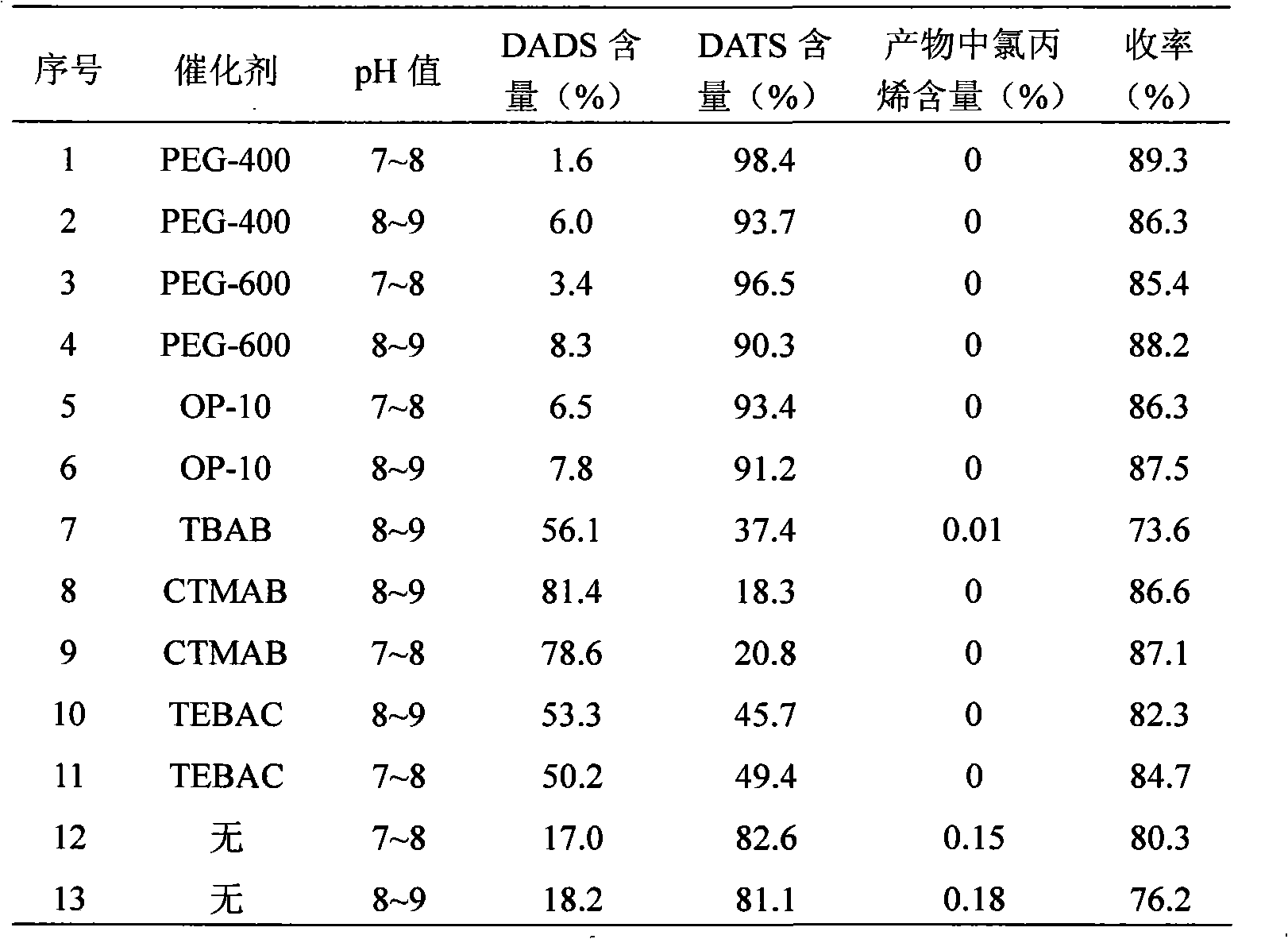

[0023] Example 1 Synthesis of garlic oil based on diallyl trisulfide by phase transfer catalysis

[0024] Put 110g (0.44mol) sodium thiosulfate, 350ml water and 0.5gPEG-400 into the reaction flask equipped with mechanical stirrer, thermometer, dropping funnel and reflux condenser, heat to 40°C, add dropwise 30ml (0.37mol ) chloropropene, reacted at this temperature for 2 hours after dropping; cooled to room temperature, added formaldehyde-disodium hydrogen phosphate buffer solution to adjust pH7, added dropwise 100ml of 50% sodium sulfide solution at 20°C and stirred for 1 hour after the dropwise addition, and stood to separate layer, and the oil layer was dried with anhydrous sodium sulfate to obtain 29.4 g of a light yellow clear transparent oil, with a yield of 89.3% (in terms of chloropropene). The product was analyzed by gas chromatography wherein the content of diallyl trisulfide reached 98.4%, and the content of diene Propyl disulfide content reaches 1.6%.

Embodiment 2

[0025] Example 2 Synthesis of garlic oil based on diallyl trisulfide by phase transfer catalysis

[0026] Put 75g (0.30mol) of sodium thiosulfate, 250ml of water and 4g of OP-10 into a reaction flask equipped with a mechanical stirrer, a thermometer, a dropping funnel and a reflux condenser, heat to 45°C, and drop 20ml (0.25mol) Allyl chloride, react at this temperature for 1 hour after dropping; cool to room temperature, add ammonia-ammonium chloride buffer solution to adjust pH8, add 50ml of 40% sodium sulfide solution dropwise at 20°C, stir for 1 hour after dropping, let stand and separate , the oil layer was dried with anhydrous sodium sulfate to obtain 19.2 g of light yellow clear and transparent oily matter, and the yield was 86.3% (in terms of allyl chloride). The product was analyzed by gas chromatography wherein the content of diallyl trisulfide reached 93.4%. The base disulfide content reaches 6.5%.

Embodiment 3

[0027] Example 3 Synthesis of garlic oil based on diallyl trisulfide by phase transfer catalysis

[0028] Put 124g (0.5mol) sodium thiosulfate, 250ml water and 0.3g PEG-600 into the reaction flask equipped with mechanical stirrer, thermometer, dropping funnel and reflux condenser, heat to 50°C, add dropwise 40ml (0.5mol ) chloropropene, react at this temperature for 1 hour after dropping; cool to room temperature, add formaldehyde-disodium hydrogen phosphate buffer solution to adjust pH8, add dropwise 150ml of 40% sodium sulfide solution at 20°C and stir for 1h after the dropwise addition, and let stand The layers were separated, and the oil layer was dried with anhydrous sodium sulfate to obtain 38 g of a light yellow, clear and transparent oil, with a yield of 85.4% (calculated as allyl chloride). The product was analyzed by gas chromatography wherein the content of diallyl trisulfide reached 96.5%, and the content of diene The content of propyl disulfide reaches 3.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com